Almost 60 years of growth and investments has enabled Bontempi Vibo to become an international leader in advanced industrial fasteners – producing over 25,000 tonnes of screws and 1 billion parts annually – all whilst still upholding the characteristics of a family business, including a personal touch.

Raoul Bontempi, CEO at Bontempi Vibo, explains: “Ever since my father started the company in a small workshop in Berzo Inferiore, Italy, in 1961, we have kept the same passion for both the quality of our products, as well as ensuring a reliable service to our customers. Thanks to our commitment to a family ethos we have been able to build long-lasting partnerships with our customers, which has been a key to our success.”

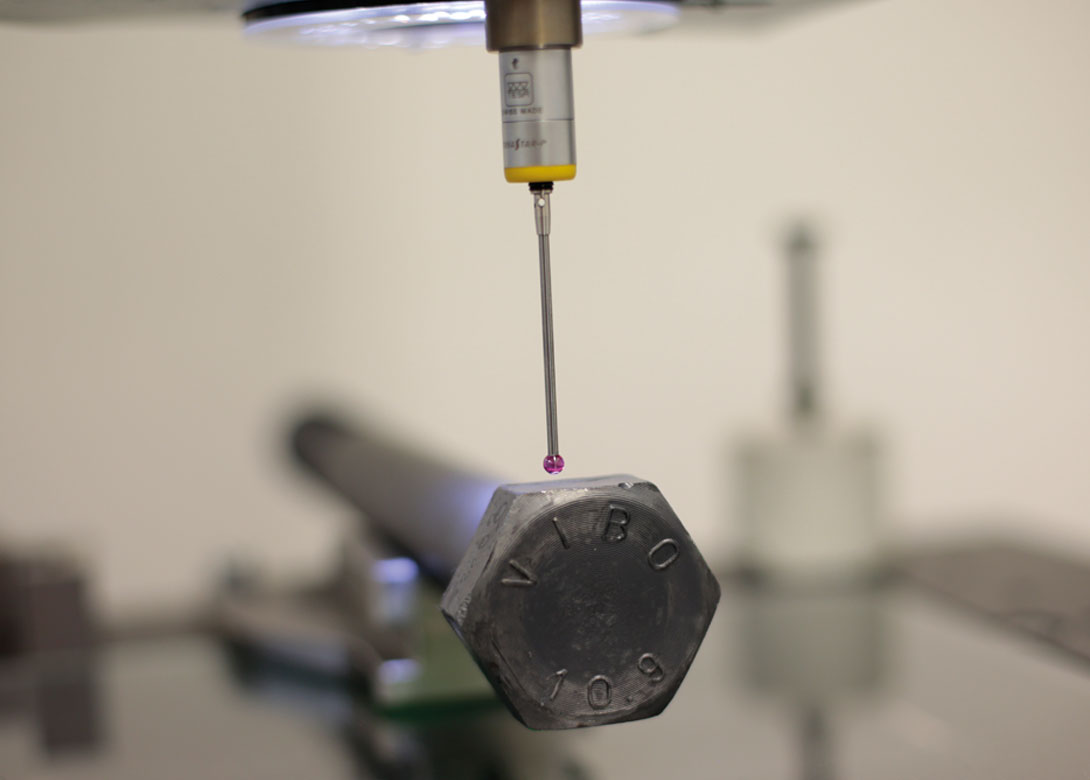

Bontempi Vibo offers a wide variety of screws and bolts and specialises in the production of hex head and hex socket head fasteners by cold forging carbon and stainless steel, in diameters M5 up to M36, as well as supplying several top quality surface coatings.

The company has three production plants in Rodengo-Saiano, Calabritto and now in Bellusco, after Bontempi acquired FRAM Srl and intergrated it into the single organisation structure at the end of 2019.

From 2020 under the Bontempi Vibo name, the production facility in Bellusco will hot forge lengths greater than 300mm and diameters up to M64. Also based at this modern, high specification production plant are three latest generation screw presses with pre-heating by induction, three rollers, and an inspection laboratory.

“Customer demand is constantly changing, and we have to be on top of that. It’s this strategy of continuously enlarging our range of products that led us to establishing FRAM three years ago,” comments Raoul Bontempi. “The founding of the business actually took us back to my father’s hot forging roots.”

FRAM was originally created to add expertise in hot forged bolt manufacturing to Bontempi’s existing wide range of cold forming capabilities. “As a business we want to continuously evolve and obtain the highest customer satisfaction levels, which is why we incorporated FRAM within the Bontempi Group. We will now continue to lead the fastener industry for cold forming and hot forging – all under the Bontempi name,” points out Raoul Bontempi.

Whilst making these changes in-house it was important for Bontempi to also retain the expertise and experience within FRAM. Marco Polato – co-founder of FRAM – is now commercial director for Bontempi Group, to help grow the business. This is not the only change to the Group management, with Vittoriano Calomeni, sales manager at Bontempi Vibo for over 15 years, the new general manager.

Based at Bontempi’s headquarters in Brescia, the Rodengo Saiano plant is also home to the sales purchasing and administrative offices, as well as the logistics, IT systems and management teams. This plant is set-up to continuously produce screws and bolts of different types, with diameters from 12mm to 36mm. The Group’s central automated warehouse, which has a capacity of over 15,000 pallet bays, is also located on the same site.

“The only way to compete with worldwide players is with automisation,” says Vittoriano Calomeni, general manager at Bontempi. “So in 2009, a fully automated warehouse with 15,000 pallet spaces was built, and there is still room to expand.”

Vittoriano continues: “We are very proud of what we have achieved at Bontempi Group. 10 years ago, at a time when the market conditions were extremely volatile, Bontempi was investing. It’s paramount we keep this level of investment and commitment in order for us to compete at not just a European level, but on a worldwide scale.”

Raoul Bontempi adds: “The warehouse itself is our main advantage when competing worldwide. It enables us to have a wide range of products and strengthens our position in the market. Our service to our customers is key and our time to market is a huge selling point.”

Bontempi has also been investing in its second plant – based in Calabritto and equipped for cold forging hex head and socket head screws with diameters from 6mm to 12mm. “Recent investments at this site include the installation of a new modern heat treatment line with a capacity of up to 1,500kg/h, as well as new machinery to enable it to produce screws with captive washers,” mentions Vittoriano. “The addition of these new machines also enables us to reduce lead times and produce the part in both carbon steel and stainless steel.”

Also housed at the Calabritto site is a raw material warehouse with over 3,000 tonnes stored on-site, along with a wire rod sandblasting and polymerisation department, polishing department, packaging department and the inspection laboratory.

Quality is at the forefront for Bontempi Vibo – with an integrated system running across all three of its production plants. “Bontempi stands for quality and is recognised on the market for this commitment. This is one of the main advantage we have – the importance of a quality product is in the product itself,” proudly states Vittoriano.

Bontempi supplies standard and special parts into a number of safety critical applications, with customers requiring in-depth documentation and specifications. Therefore investment in a new MES was of paramount importance to Bontempi Vibo to ensure a consistent high-quality approach. “The new MES collates all the production data, quality specifications, and manufacturing information, to one central system,” explains Vittoriano. “This system also enables customers to receive information, updated in real time, about stock and able to access ‘virtual stock’.”

The company can also arrange visits for end users in order to gain approval as a quality supplier. “Industries such as nuclear need us to work with the end user from the design stage for the bespoke critical parts. Our aim is clear,” comments Raoul Bontempi, “quality, quality, quality”.

Vittoriano adds: “We must also now concentrate on Industry 4.0. This philosophy will enable us to continue to grow and make our offering even more desirable. To us, the product we sell is the screw and our service. Its a whole complete package in order to fulfil our customers’ needs.”

“There’s plenty of opportunities for Bontempi Vibo to invest in not only our operations, but also our people and services. We’re open to all possibilities and we will continue to grow. We’ll still be here in another 10 years and we’ll be bigger than we are today – both through our product offerings and our worldwide reach. It’s an exciting time for us here at Bontempi Vibo.”

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.