Based in Keighley, UK, GESIPA UK was first established as a subsidiary for German-based GESIPA Group in 1971. Today it is the Group’s centre of excellence for threaded fasteners, and structural rivets, and is constantly looking to increase capacity and produce new innovative products.

By looking at the trends of the markets, such as lightweight fasteners, GESIPA UK is focused on producing innovations and new products developed internally. “Innovation is the lifeblood of our business and comes from listening to the markets you serve. This includes looking at new applications, changes to manufacturing processes and/or new ideas for cost savings.”

“Within the Group we also look at market trends and future needs for the fastening technology – such as asking ourselves what we need to change with our current fasteners to meet these requirements. Obviously, this is not just related to products but also the way we engage with our customers,” comments GESIPA UK. “That is why we have launched a new online ‘chat’ function, as a way of connecting with current and potential customers.”

The difficulties in the automotive market over the last nine months, and the uncertainty of BREXIT, has made it a challenging time in the riveting market. “Our strategy for BREXIT has been to manage the ever-changing situation and ensure that we make it as easy as possible for our worldwide customers to trade with us,” explains GESIPA UK. “We need to stay one step ahead as potential tariffs and extra export paperwork going forward could cause issues.”

With BREXIT being a key focus for most UK businesses over the last 3 years, GESIPA UK is also keen to point out the benefits of being a UK manufacturer, such as its employees. “We have a very strong, reactive, loyal and stable workforce who align to the values of the business. Our employees are highly skilled and this ensures we can support our customers with sample design. We also offer technical advice direct to our customers.”

Demonstrating its range

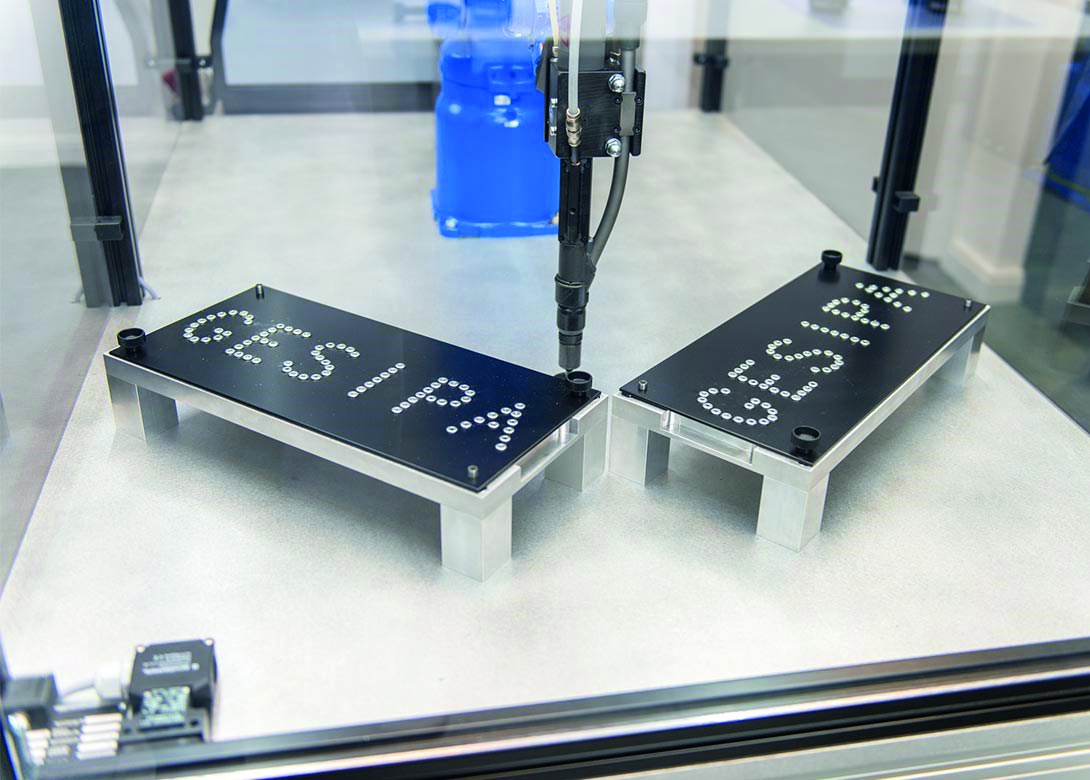

To showcase its wide variety of tools, GESIPA UK has a demonstration centre at its Keighley site, which includes battery powered hand tools in its Bird Series – including AccuBird® and PowerBird® – as well as its popular Taurus® series of pneumatic hydraulic blind rivet setting tools. There are also robotic riveting systems on display, such as the GAV range of automatic riveting machines.

Also included in the centre is a flow drill riveting tool – FDR® – which is a pre-punch-free riveting method that GESIPA says will revolutionise mechanical joining technology. Designed as an automated process, with full process monitoring, the FDR method requires no pre-punching and no hole finding – combining drilling and riveting in one process. With a rotation of 6,000 revolutions a minute the FDR system’s specially designed rivet head, rotation, and joining force, allow the blind rivet to penetrate into both light metals and plastics.

“The FDR system is perfect for working with aluminium material and is an example of how we are constantly moving forward with new technology,” points out GESIPA UK. “This is the forefront of design. It might not be something for every company, but it shows we are offering brand new technologies for the leading players.”

Having the demo centre enables GESIPA UK to show customers the range of tools it is able to supply. Customers can also get ‘hands on’ experience of using the tools and see how the automated systems will benefit their operation. “We love showing people around, so they can fully understand the products and services. We often find customers will come to us with a set idea with what they want, but after using the tools and understanding the different capabilities, they often decide on a different type.”

“We offer the complete solution – fasteners, tools, process control and automation – with our technical teams working directly with the customers. GESIPA is a respected brand manufacturer with excellent relationships, which we pride ourselves on.”

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.