Through its knowledge and experience within the market, as well as its commitment to continuously innovate its products and service, JCP Construction Products has established itself as a technical expert within the fixings sector.

A specialist supplier of construction fixings to distributors, JCP Construction Products (JCP) has developed a reputation for its technical insight and experience in applications and fixings.

“Whilst our target market is fixing distributors, we have created close relationships with engineers and end users on construction sites, so we can demonstrate the capabilities of our solutions,” states Nick Beardon, general manager at JCP Construction Products.

By talking directly to the engineers on-site, JCP can demonstrate the features and benefits of its products and how they can help save installation time and improve applications. “The user can see first-hand the capabilities of the fixing, which can be especially helpful when you come across somebody who is accustomed to using a particular part,” points out Nick.

“By talking to them face-to-face, and carrying out demonstrations, they can see the advantages of our solution. It is only by having this connection with end users that you can ensure your range is meeting their needs. We can then be confident the portfolio we are supplying to our fixing distributors are right for the market.”

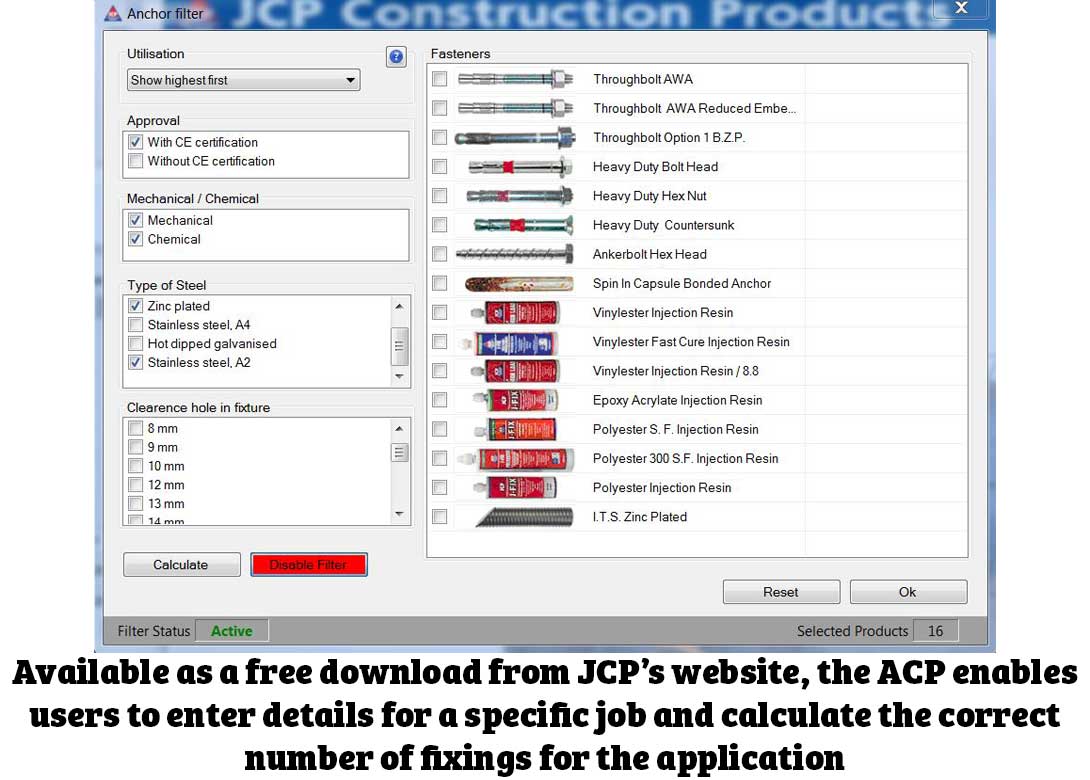

Anchor calculation program

JCP also looks to provide the right services to end users, such as its Anchor Calculation program (ACP). Available as a free download from JCP’s website, the ACP enables users to enter details for a specific job and calculate the correct number of fixings for the application. “There are a host of data sheets that provide the necessary information for applications that fall within set boundaries,” explains Nick. “However, it is when you get outside of these scenarios – regarding edge distance, anchoring spacing, and various embedment depths – that end users need help and that is where the ACP comes in.”

The ACP includes a wide range of information and data, including fire and seismic requirements, and can accurately suggest suitable anchors and base plate configurations – making calculations according to European guidelines. “We have recently updated and reformatted the software so it is more efficient and we have also added an additional program for rebar, which can calculate the amount needed for an installation,” mentions Nick. “We are also looking to develop the ACP further by introducing a program for façade fixings in the future.”

Nick adds: “If you are going to compete with the leading players with the fixing sector, you need to be able to offer a competitive service. An anchor calculation program is becoming an important part of that service and is crucial if you are going to appeal to the decision makers on-site. By doing this you get the pull through demand from the engineers, who go to the fixing distributors and ask for our products – as they know they will get a high-quality solution and a first-class support service.”

Reliable quality

Whilst additional services are important, the need for quality is still the leading factor in meeting end users’ needs. “Without doubt the market has become a lot more aware of quality and certification, especially regarding health and safety,” states Nick. “As a company we are committed to quality and we are confident in the performance of our products, with several being supported by European Technical Assessments.”

Nick continues: “The introduction of the Construction Products Regulation (CPR) over three years ago put quality at the forefront of people’s minds and did lead to engineers looking at the quality of the overall process. However, we are now getting to the stage where it has become more of a ‘tick box’ routine, rather than end users continuing to focus on the quality benefits. For instance, site tests are now an essential part of our service. Going back even just a decade you would normally do site tests on just the bigger projects or for new customers – when the specification had been changed and they wanted the quality reassurance. Now we are doing pull out tests five or six times a week – primarily for parts that are already being used on-site. The end user just wants the certification to say it has been carried out. In fact, we are even being asked to visit sites to test ETA certified fixings, which we shouldn’t need to do as the certification proves the capabilities of the products.”

“As a business going to sites has always been part of our service, so we are happy to meet customers’ needs. We have always carried out these tests and we will continue to do so in the future.”

New pouch bag range

Whilst JCP looks to work closely with the end users and engineers, it is also focused on offering a complete service to its fixing distributors, which is underlined by the introduction of a new pouch bag packaging line – covering popular products and sizes for a wide selection of fixings. “The new JCP pouch bags offer the highest level of quality, with the bags being strong and robust, as well as resealable, drop-proof, water resistant and easy to identify – making them ideal for working on-site,” explains Nick. “The pouch bag line also includes an updated labelling system on the bags, which provides a lot more information, such as hole diameter, fixture thickness, range available, capabilities, etc. There is also a picture of an installed product on the front, as well as a QR code that takes the user to the technical data on the website.”

In addition to the pouch bag, JCP has also introduced a retail range that offers a similar offering as the pouch bag, but in small pack quantities. “We have already introduced the pouch and retail packaging lines to our existing fixing distributors and they have been very well received,” points out Nick. “With the bags the first thing you see is the JCP logo and then the product, as well as the informative label giving the customer all the information they need – making the choice for customers quick and easy.”

Endless development

The new pouch bag range is just another example of JCP always looking to innovate and introduce new developments and products where possible. “As a business we are focused on new ideas that will benefit the end users,” says Nick. “We carry out in-house research, work closely with engineers, and study upcoming regulations and standards, to see what opportunities there may be in the future. In addition to new products lines, we have found adding additional benefits and improving an existing range is just as important. It shows as a business you are in a constant process of development.”

A prime example is the recent introduction of JCP’s range of premium nylon plugs. “We took the existing range and added extra benefits such as additional pull out test results on various substrates – brick, concrete and blocks – so we now have loading data for this range,” mentions Nick. “We also have two or three new lines we are planning to introduce in the coming months, which will further extend our existing range.”

Another area that has been successful for JCP is getting products confirmed in projects. “We are starting to see our solutions specified in projects, which is a real ‘feather in our cap’,” states Nick proudly. “The bigger companies have engineers working in drawing offices day in and day out, but we don’t have the man power to do this. Therefore, to see the drawings say ‘JCP’ and our codes, is a real achievement and shows the level of service and technical knowledge within the business.”

Preserving technical knowledge

As with many sectors, keeping the technical knowledge within a business and introducing the next generation is a big task, but it is something JCP is already working on. “As a business you need that understanding if you are speaking to the end user, you can’t just know the product number and the catalogue price,” explains Nick. “That is why we have already taken steps to start the knowledge transfer.”

Firstly, JCP has replaced experience with experience, with Karl Greenwood joining the business as area sales manager – replacing Pete Gaster who recently retired. “Pete had virtually been with the business since the beginning and had a lot of knowledge of the products and the industry,” points out Nick. “It was therefore vital his replacement also had a similar longevity within the fixing industry. Karl Greenwood is vastly knowledgeable and will be a good addition to the team.”

JCP has also introduced an extra employee within the technical department to learn and understand the technical aspects of the business. “Brian Deluce, our technical manager, was 70 years old in August but he is still working with us. Over the last two years Reza Jafari has been working alongside him and developing the understanding of the business and products – helping keep the knowledge within the business. The key is finding people that are enthusiastic about the product and the job they are doing, which is not as easy as it sounds.”

Targeting growth

JCP is currently focused on the UK market, but moving into Europe is a growth target for the future. “In the UK we believe we are number three in the market when it comes to supplying industrial fixings to distributors,” states Nick. “Some companies might have a higher turnover, but a large part of that is into the DIY sector. Whilst we are established within the UK fixing sector, we are still relatively unknown in Europe. However, we know we have the products and service to compete, so it is a case of getting involved and making European customers aware of what JCP has to offer.”

A big advantage for JCP is that not only does it benefit from being an SME – flexible, responsive, personal service – it also has the added benefit of being part of Hexstone Group. “Being part of a bigger organisation such as Hexstone enables us to invest in JCP and in new opportunities. We have the financial resource that allows us to invest in new products, as well as research, testing and certifications – such as European Technical Assessments and fire regulations.”

“As a business we will continue to look to develop where possible, whilst always ensuring we are providing our distribution partners with the right products, as well as working closely with engineers on applications.”

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.