Thanks to its highly skilled technical staff, Regg Inspection Srl is able to design and manufacture high-quality inspection systems.

Regg Inspection designs and manufactures inspections systems with modular design that can be equipped with vision systems, mechanical recess control, 360 degree profile check, eddy current crack detection, hardness control, and other special applications.

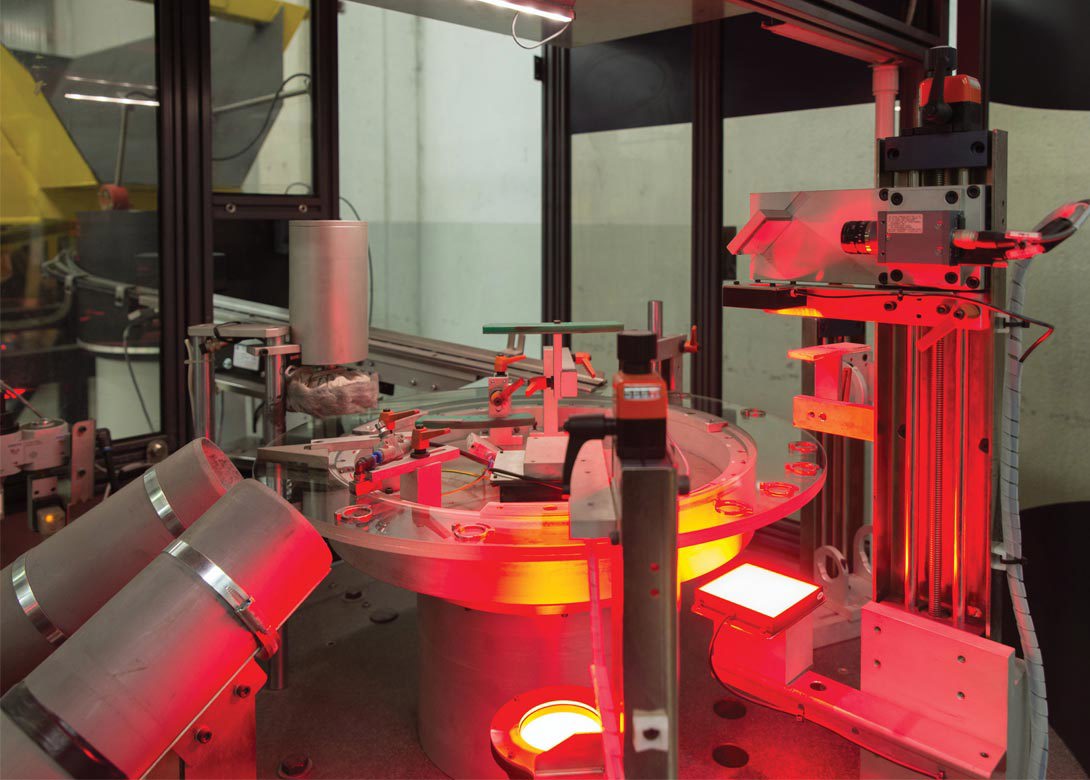

Regg Inspection’s machine range includes the i300 machine series, which has been designed for fast and accurate vision inspection needs. The main features include the latest vision technology, up to five high resolution cameras for the most comprehensive part inspection, as well as patented 360 degree thread integrity control.

The company is also able to offer the i600 machine series. In addition to five high resolution cameras and 360 degree thread integrity control, the series also offers a two tier granite base foundation for strength and stability – which Regg Inspection says makes it the most robust machine in the industry. Other features include a wide rotary table for fast and accurate inspection for up to eight inspection modules, as well as patented mechanical recess control and non-visible crack control with eddy current.

The final series is the i900 linear machine, which has been designed for fast and accurate vision inspection needs of flat or headless parts. This series includes up to four high resolution cameras for the most comprehensive part inspection.

Each series also includes a fully integrated feeding system for smooth and fast inspection, as well as fast and easy set-up and changeover design. An intuitive Man Machine Interface (MMI) also makes it easy for both operators and programmers to use.

The vision system instruments replace several expensive, traditional measuring tools such as callipers and dedicated benches. For instance, Regg Inspection’s i360 is independent from temperature variations. The measuring is reliable and free of potential manual mistakes of operators. Designed and developed by the company in close cooperation with its customers, the i360 is also manufactured to be a reliable and precise measuring instrument, while being designed to be easy to use. All measurements are taken all at once in less than a second.

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.