Amanda True became managing director of Fastbolt UK at the end of 2018, having taken over from previous MD Graham Joyce. Editor Will Lowry caught up with Amanda to see how the last 18 months have developed and the plans she has for the future.

Having joined Fastbolt UK in 1997 and been appointed IT director in 2011, Amanda has a vast amount of experience and knowledge of Fastbolt, and the industry, which she needed to call upon when becoming MD. “The last 18 months seem to have gone by in a blink of eye, with a never-ending list of surprises and challenges – whether it has been BREXIT, Covid-19, or other unexpected topics and projects,” says Amanda with a smile. “I am hoping things will eventually calm down, but it hasn’t happened yet. However, I have enjoyed every minute and I have received fantastic support from the team at Fastbolt. This has enabled me to handle these big topics, settle into the role and move the business forward.”

Whilst BREXIT might be at the back of people’s minds, Amanda believes it will soon return to the forefront. “BREXIT has been a big topic that we have been working on and we can already see things changing. For instance, I know there are a lot of commodity code changes happening in preparation for next year, so we have been working with our clearing agent who has been very helpful. It is difficult to plan a certain path, when you don’t know where that path will end up, but it is about positioning ourselves to whatever changes may occur or documentation that may be needed. By doing this we can quickly introduce the necessary steps to our processes and practices as and when necessary.”

Amanda continues: “As a business we are in a strong position because we have the support of the head office in Germany – so we have solid foundations both in Europe and in the UK. This means whatever the final ‘deal’ we should be able to react positively. The key now is for a decision to be made and clear guidelines given so we can manage the situation.”

In the last 18 months Fastbolt UK had to also bring in a new freight forwarder, after its previous forwarder went into administration. “We only had a week and a half to introduce a new forwarder, but thanks to our SAP system we had a lot of the structure and required data in place, so it was made a lot simpler,” explains Amanda. “The automatic inputting of data and the organisation of the entire process has always been held in the system, so it was vital this remained the same with the new forwarder. If the warehouse had to start inputting data, it would be a big step back, so it was a key factor in the considerations.”

After finding the right forwarder it was then a case of connecting the two systems. “The ‘onboarding’ process was very quick and we were able to stage the process over a couple of days – before the old forwarder went fully into administration – which was a big positive for us. We were able to introduce the new forwarder and there was minimal impact on customers’ deliveries.”

The next challenge for Amanda and the team at Fastbolt UK was the outbreak of Covid-19. “Again, I think this is where we benefitted from having a company in Germany, because it meant we already had a lot of remote access in place,” mentions Amanda. “Due to the connectivity between the two branches, we were already established on Microsoft Teams with certain members of staff and we also had the relevant connections, set-up, and back-ups, for accessing the systems offsite. This meant it was simply a case of giving more people access to these services and we could then carry on running the office and sales. This enabled us to have a mixture of people working from home and some in the office. It was also necessary to furlough some of the staff.”

Due to the size of its warehouse, the company was able to quickly introduce social distancing for warehouse staff. “This was another big positive as it meant we could keep our staff safe, whilst also sticking to our cut off times for orders and meant we could still provide the service our customers expect,” points out Amanda.

Fastbolt UK has also been able to successfully manage its supply chain throughout the pandemic – through its inter-company deliveries. “We get a mixture of products from the Far East and from our head office in Germany, so this helped us manage our stock levels,” explains Amanda. “When Covid-19 hit the Far East, there were some delays, but we were able to manage this situation and these have now been resolved as lockdowns have eased. Throughout the period we kept in contact with our suppliers to see how they were handling the situation. With our inter-company deliveries, we initially reduced the frequency, so instead of one every week we had a fortnightly delivery. However, that has changed again, and we have gone back to our weekly delivery. We are therefore back to normal regarding stock and we are at a similar stock level as prior to Covid-19.”

A key factor that has enabled Fastbolt UK to handle all these situations, and ensure it is able to supply the products and services customers expect, is the SAP system that has been in place for almost 20 years. “The decision to go with the SAP system was definitely the correct one and it has helped us develop as a business significantly,” points out Amanda. “Through upgrades we are able to keep the system up to date and it enables us to streamline processes significantly and drill down into the relevant data. We can also transfer data or download data in the correct format and it has helped us get rid of a lot of ‘paper processes’. Put simply, it provides the visibility we need as a business to make the right decisions.”

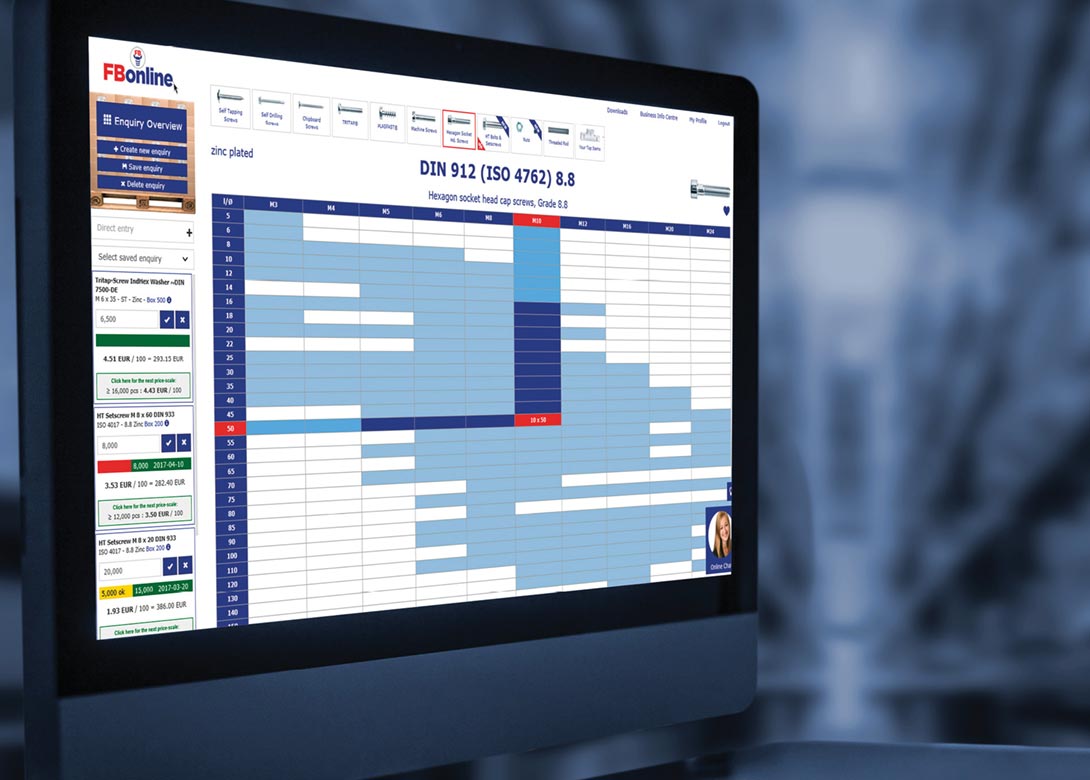

Another platform Fastbolt has developed over recent years is FBOnline – where customers can access the latest stock details and place orders 24/7. “We have been active online for a long time and have developed the platform so it provides all the necessary information and details customers require. It doesn’t matter where the customers are, they can access this information and see our stock levels, as well as their own account details – previous orders, etc,” mentions Amanda. “Customers can even load data from a Microsoft Excel spreadsheet and it will go straight into our system.”

Amanda adds: “We already had a large number of customers that carried out their entire order process via the online platform, but with the outbreak of Covid-19 we have seen the number of people accessing the platform increase and we believe this will continue in the future.”

However, for the remainder of the year it will be Covid-19 and BREXIT that will be the centre of Amanda’s focus. “Going forward, it is about being able to react quickly in terms of lead times and ordering. That is an area we are focusing on and always looking to improve, as well as procedures and processes. We will also continue to look at the different product ranges we can offer. We have a wide range of products, but we are always reviewing them according to customers’ needs.”

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.