With over 60 years of experience, BENERI has the expertise, knowledge, production, and commitment to quality, to meet the retaining ring and washer needs of the global market.

BENERI SpA is still a family-owned company, with the third and youngest generation now fully involved in the business and looking to the future. As a leading manufacturer of standard retaining rings and washers, both in metric and inch dimensions, the company is able to supply products that comply with DIN standards, as well as a variety of special solutions.

“In the last decade, we have invested a lot in quality and have introduced several additional quality checks in each step of the production process to guarantee the highest quality levels for our products,” states BENERI. “We have also ensured we have a huge stock of our product range that can be delivered quickly to customers globally.”

Thanks to its know-how, and constant technical research and investment in the optimisation of the production processes, BENERI has also been able to develop new products – such as its new ‘Automotive’ range of retaining rings, which is a top selection of standard retaining rings (DIN 471/DIN 472) that have successfully passed strict quality checks regarding dimensions and flatness. “We highly recommend this range for applications with automatic feeding systems (automotive or electronic devices industries),” points out BENERI.

Thanks to its know-how, and constant technical research and investment in the optimisation of the production processes, BENERI has also been able to develop new products – such as its new ‘Automotive’ range of retaining rings, which is a top selection of standard retaining rings (DIN 471/DIN 472) that have successfully passed strict quality checks regarding dimensions and flatness. “We highly recommend this range for applications with automatic feeding systems (automotive or electronic devices industries),” points out BENERI.

Other products that BENERI has used its expertise to develop include the design of its original toothed washers type DIN 6798 A with overlapped teeth and knurled washers, with milling on both bearing surfaces. “We have been producing standard washers since 1958 and even with the low prices available from Asia, we have been able to stay a key player within the market thanks to the high-quality we produce and our ability to manufacture products that meet customers’ needs,” explains BENERI. “We hope that the recently announced anti-dumping duties will bring back some of the old business that we lost to Asia over the last two decades. Thanks to the investments that we have continued to make over the years, we are ready and well equipped to support this new increase in demand.”

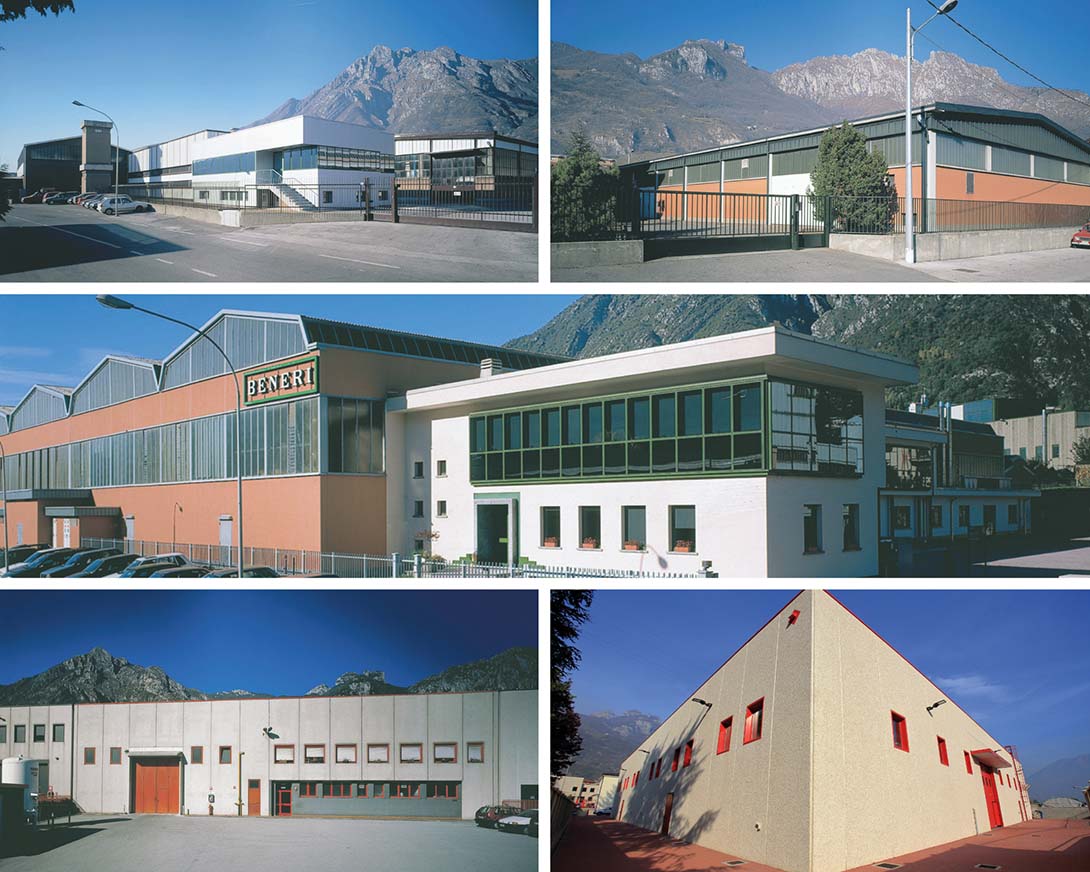

BENERI has a wide production capacity, with parts designed and produced in five production units located in Valmadrera (LC), Italy. These different units also played a significant part in the company being able to quickly adapt to the challenging Covid-19 pandemic and guaranteed that the necessary protocols could be introduced. “Our top management soon recognised the potential risk of the virus and immediately set-up an internal protocol in order to keep working whilst avoiding any possible infection. This included distance between employees, masks, deep sanitisation of workspaces and tooling, etc,” points out BENERI.

During the Covid-19 pandemic BENERI also noticed a shift in customers’ buying habits, with the company’s huge stock putting it in a strong position to meet customers’ needs. “We saw demand increase quickly, as competitors were finding it hard to get raw material and transportation – especially sea freight – it was a big mess,” points out BENERI. “Thanks to our huge stock we were able to supply our finished parts to customers and this helped many businesses. We believe the pandemic underlined the benefits of having a local supplier and we hope it will lead to a change in buying habits for the future.”

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.