Ambrovit strives to be a fundamental, professional and reliable partner for its customers. It does so through investment in its production technology, as well as through investing in its human resources, which it says is the real ‘engine’ of all production activities.

Ambrovit strives to be a fundamental, professional and reliable partner for its customers. It does so through investment in its production technology, as well as through investing in its human resources, which it says is the real ‘engine’ of all production activities.

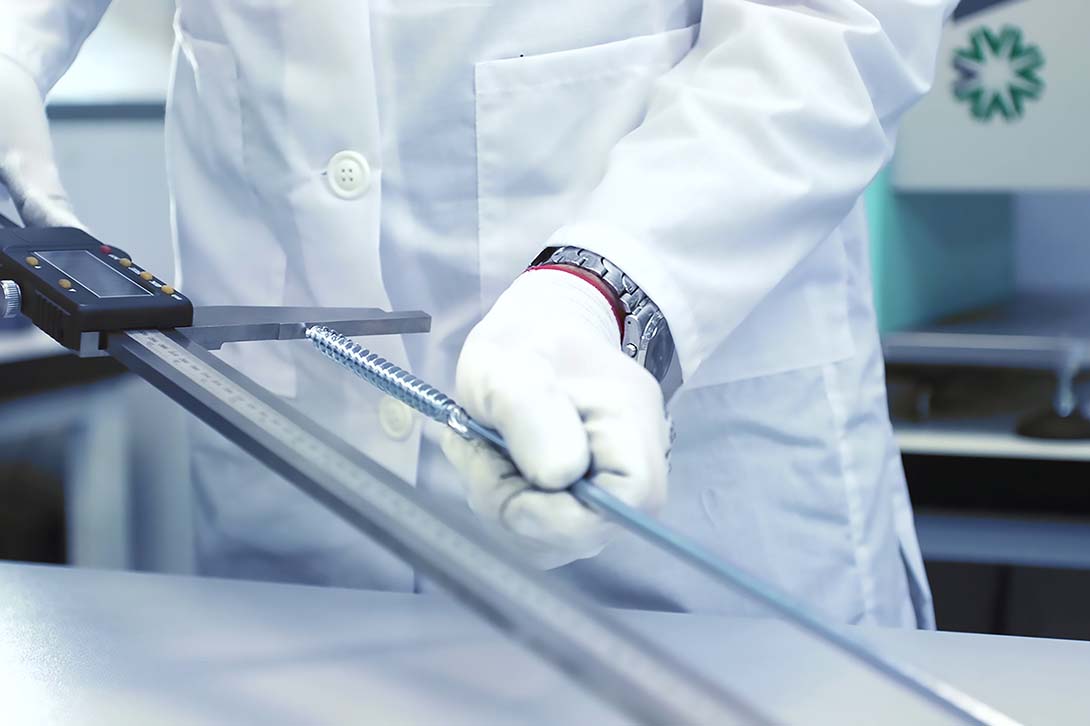

Part of Ambrovit's DNA is to constantly update its own technology, for both logistics and product management, with the aim of optimising the processing steps in order management. Every innovative project that Ambrovit carries out has a primary objective to guarantee customers an excellent service, such as prompt delivery, order control, timely shipping and aftersales assistance. This means qualified personnel assist the customer by providing information and expertise on the use and specification of products in case of special applications.

“Without presumption, we can proudly say that the inclusion of more than 10,000 items in our catalogue has enabled us to continue to meet the demands of our customers – even in these challenging times we are facing,” comments Mattia Sozzé, quality manager at Ambrovit. “The rising costs of raw material and anti-dumping duties are among the factors that have contributed to the challenges faced by distributors but, while feeling the burden, we believe that maintaining the high standard of product quality and the quality of customer service is the winning strategy. It must also be said that, so far, the market understands the necessary variables and maintains a strong demand.”

It is this demand that has seen Ambrovit have a strong first half of 2022 – giving hope for an interesting year. “In recent years from a commercial point of view we had no particular market declines, but have maintained positive numbers, increasing year by year. Logistical problems such as in the production and commercial sectors, have been addressed by effective and objective programmatic reorganisation, which has allowed us to respond exhaustively to market demands. For now, everything gives us hope that the growth in logistics issues will stabilise, because only by finding a balance we will avoid seriously compromising the market in our industry.”

“For the future we have many plans - Ambrovit is always in constant evolution,” concludes Mattia Sozzé. “In the world of fastening, where the main material is metal, sustainability is important within the supply chain. Because of this, Ambrovit is particularly sensitive and attentive to product finishes, packaging, quality of the working environment, as well as the use of sustainable in-house operating products. Ambrovit will continue to do its part.”

www.ambrovit.it/en

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.