Daniel Suárez became CEO at Bralo Group in July 2019. Here Editor Will Lowry speaks to him about how he has settled into his role and the steps Bralo, as a global company, has taken in handling what has been an exceptionally challenging 18 months.

What made you decide to join Bralo Group and what have been the key developments at the company since you became CEO?

“Bralo is a family company that was founded 40 years ago by Basilio Lopez – who was CEO throughout this time. Three years ago, he decided to take a step back from the day-to-day management and therefore wanted somebody, from outside of the family, who could help the company take the next step in terms of professionalisation, development and growth. However, the family is still very present in the management team and regularly reviewing business performance.

That is how I joined Bralo and I must say I foolishly believed working with rivets, and the fastener industry, would be relatively straightforward, especially as I was coming from the automotive sector where there is a lot of complexity. However, I soon realised when it comes to the fastener industry there is also a lot of complexity, as well as a lot of engineering and work behind everything.

Over the last 18 months Bralo has developed a lot and has taken big steps in a number of areas, which has put us in a strong position within the market. An example is that we are an IATF 16949 certified company, which is mandatory if you want to deliver parts into the automotive market and work closely with these customers as tier 1. There have also been a lot of developments in our product portfolio and our machines, as well as how we work alongside our customers.

At Bralo we look to solve the necessities and problems of our customers. For us the best customer is the one that comes to us with a fixing request with certain elements or has specific requirements. When this happens, we can work with the customer on finding the most adequate product or even run a complete development process. We can do this thanks to the strength and knowledge within our R&D team – enabling us to deliver the most targeted solution for every customer.”

Tell me a little bit more about Bralo’s R&D department and how it helps you support customers?

“In our R&D team we have people working on designing the products, designing the tools and designing the machinery, therefore, meeting the complete need of our customers. They are very well trained and have a lot of experience, which means we can provide the right solution for every customer.

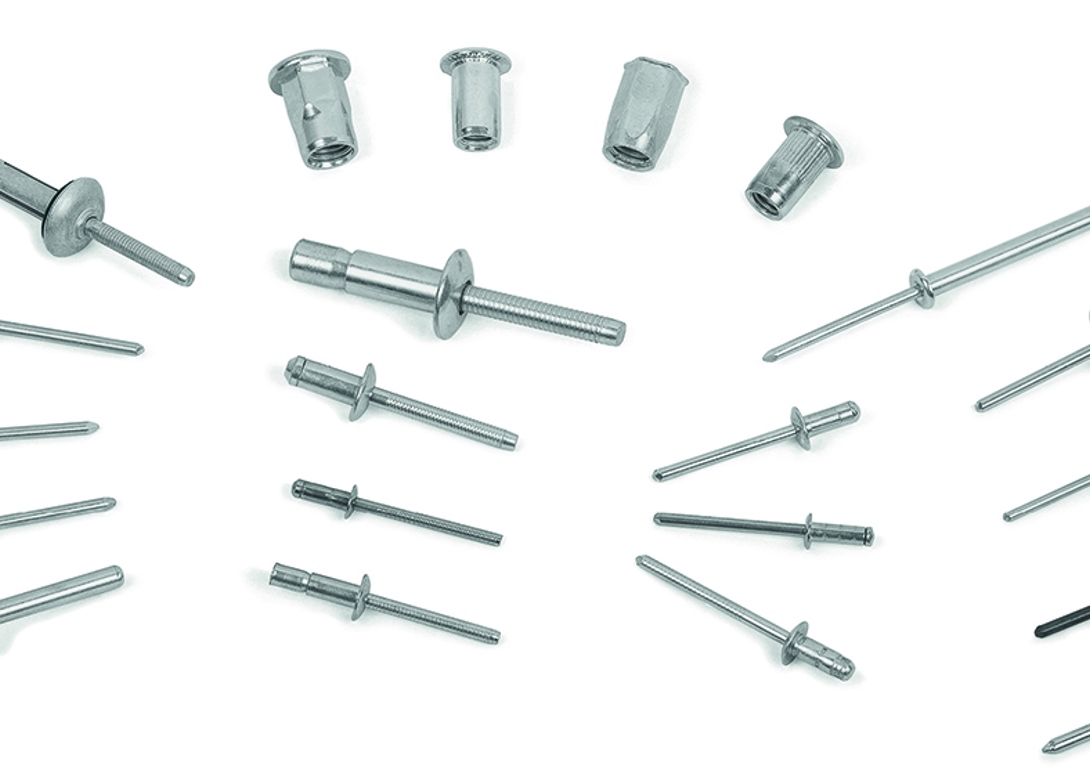

Normally customers come to us with a very concrete demand, but when we need to develop solutions, we try to make sure we get a bespoke product that meets the customer’s needs. A blind rivet is very easy to select, you just need to know the diameter and the thickness of the plates to join. However, there are a lot more particularities to consider when designing something special. For instance, in the automotive sector there a lot of parts made from plastics and the behaviour of a rivet in plastic is not the same as in metal, so this is something you need to consider when designing a solution.

The EV market is another interesting sector for us. For instance, many of the battery supports for EVs require a lot of fastenings. Thanks to our R&D capabilities we are able to work on solutions and we have a wide range of insert nuts that are perfect for these types of customers.”

What challenges did the Covid-19 pandemic present to you as a company over the last 12 months?

“The first thing for us was the safety of our team, so straight away we created protocols to keep all our employees safe. The second big thing was to keep our production in Spain running, which we managed to achieve from the very first moment. The plant was closed for only two weeks and this was due to the fact it was made mandatory across the whole of Spain. Even during that time we still committed to supplying product to essential business that were running (for instance hospitals or maintenance of essential facilities).

In fact, I remember the weekend when the government in Spain announced the lockdown of the complete economy. The first thing we did at 10pm at night on the Saturday was discuss how we were going to continue supporting our customers. 14 hours later, at 2pm Sunday, we had trucks departing from Spain to create a special stock for key customers in our warehouses across Europe. This guaranteed they had the products in case there were any issues during the national lockdown in Spain.

Whilst the Covid-19 pandemic was very serious and a difficult time for everybody, it did also bring us some opportunities. As we all know there are a lot of companies that buy their products from the Far East, because of the price. However, with the impact of Covid-19 there was a lack of availability, which enabled us to step in and help new customers who could not get stock.

This created more business for us, which has continued as lockdowns have eased – due to the lack of containers currently available globally. Companies are having difficulty bringing products in from China, which means customers have stayed with us and are really starting to understand the value and quality we can deliver.

I think going forward customers will definitely think twice about going to Asia simply based on price. Longer delivery times; uncertainty in supply; container prices; sea freight availability; as well as the practicality of auditing suppliers; are all factors companies have to consider. The pandemic has also shown how global supply chains can quickly struggle due to unforeseen circumstances. All of this I am sure will provoke changes in people’s mentalities regarding sourcing fasteners in Europe.”

How important have the services you are able to provide customers been during the pandemic? How did you manage your supply chain?

“In the fastener industry what the customer wants is to get the products as quickly as possible. They want to call, make an order and get a quick delivery. That is why at Bralo we make one of our main selling points the availability of our wide range. Having seven warehouses all around Europe, as well as factories in Mexico, China, and Spain, enables us to support customers with this availability – wherever they need it.

For instance, when the pandemic first broke out in China the country stopped for 7 – 8 weeks. When this happened, we were able to move some of the production from China to Spain so we could continue to supply our customers. Also, we increased our stock in our warehouses across Europe so we could support our customers very quickly.

Something important about Bralo is that regardless of the plant – Mexico, China or Spain – they all produce to the necessary European standards. This includes the material used, the products, the machinery, everything involved in the production process. This helps ensure the products manufactured by Bralo, regardless of the plant, are of the same high-quality.”

What do you think will be the long-term impact of Covid-19 on you as a business, as well as the fastener market in general?

“It is clear the use of digital technology in the day-to-day running of a business will become more important. For a number of years, we have made sure our product portfolio is available online and that we can communicate with customers electronically. I believe going forward the whole fastener industry will develop a lot quicker when it comes to digitisation, especially when it comes to business relationships.

We will not be flying as much as we did in the past, because we have learnt we can still do business as successfully remotely. You can have a meeting with a customer in Asia in the morning, a customer in Italy in the afternoon, and in Germany at the end of the day, without leaving your desk.

Bralo has always seen digitisation as a key part of its development and we are in a good position should a customer ask us how we can work closer with them.”

What are the company’s plans for 2021 and beyond? What do you see as being the big trends for the fastener industry in the future?

“For the rest of the year it is a case of just managing the current situation and the turbulent market. Ideally, we would like to grow and in January we actually managed a 4% growth compared to 2020, when the pandemic had not yet hit.

Another key strategy for us is to introduce new products. We have recently started a big project to renew our BNT range of pneumatic riveting tools. We have reviewed all the products in the market and we have identified our lines for the next generation of tools.

As for trends, as previously mentioned I think where customers have been pressing the importance of price, this will change to focus more on quality and reliability. However, whether it is price, quality or reliability, at Bralo we are confident we can compete with anybody within the market and provide a service to customers that is unrivalled.”

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.