In 2021 Bodegraven Metaal celebrated 40 years in the industry, having become a well established company that exports around the world whilst producing only one product – threaded rods.

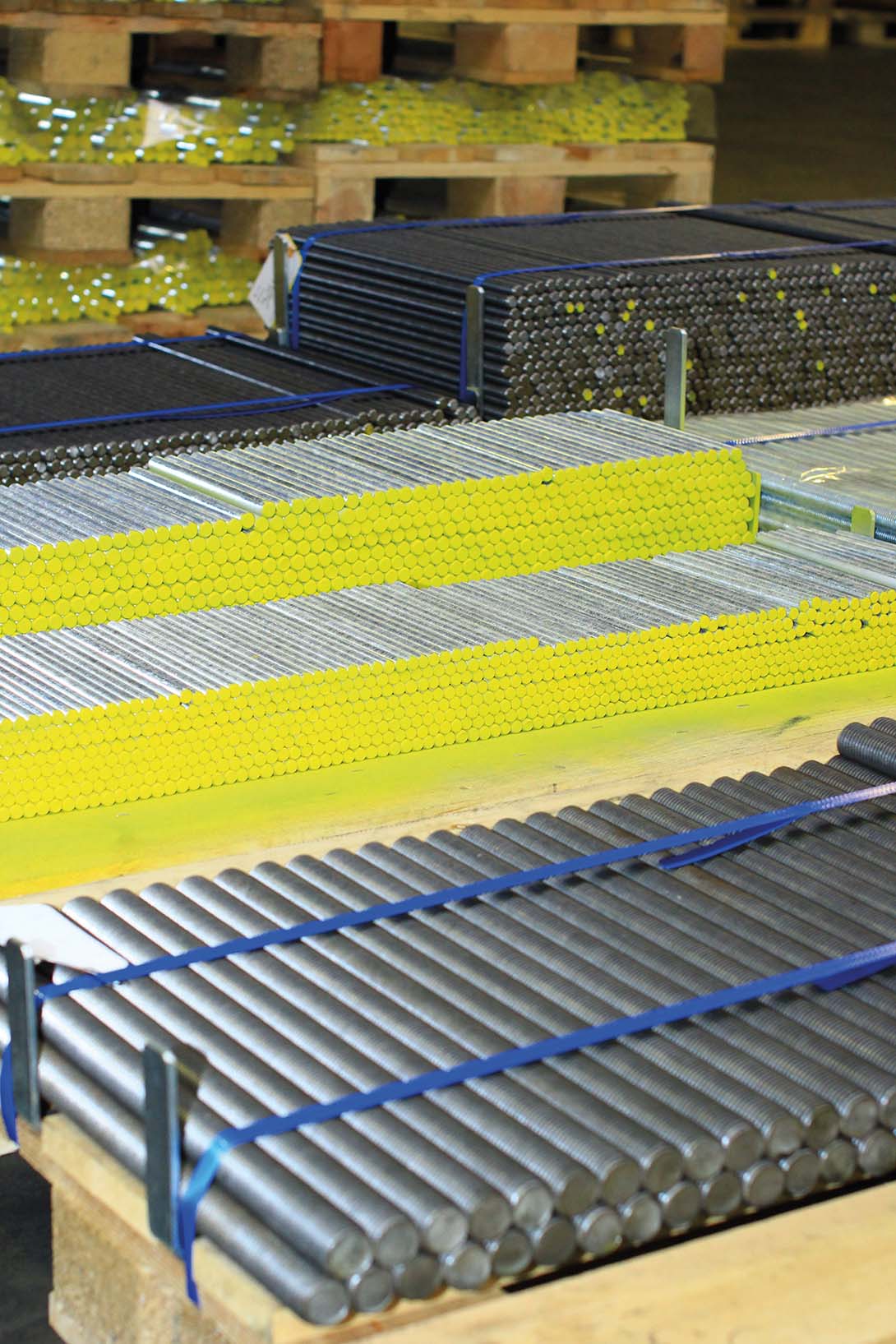

Bodegraven Metaal N.V (BOMET) is able to supply a whole range of threaded rod (DIN 976-1) from M3 to M60 in lengths 1m, 2m and 3m, as well as cut to size. A key factor in BOMET’s capabilities is its focus on continuously improving the automation of its production, which it believes helps it stay ahead of its competitors within Europe and Asia.

“We develop and assemble our machines ourselves, which gives us an undeniable advantage,” states BOMET. “It means we can ensure our machines are designed exactly how we need them to work and we can automate them so they are very efficient. The labour cost in Belgium is one of the highest in the EU, so we have to focus on automation.”

BOMET has introduced a number of machines over the last year in order to further increase its production capacity and meet the needs of its customers. “With only 35 employees we can guarantee an output of 15,000 tonnes,” states BOMET proudly. “This brings us to the forefront of the threaded rod industry.”

Another area that BOMET has looked to develop and meet customers’ needs is the demand for special lengths, which is a growing sector. “We have found that there is still very little cutting on the construction site – customers like to buy a fixed product,” explains BOMET. “This is another reason why we have invested a lot in automatic cutting machines in recent years, in order to follow this trend and shorten the delivery time to a few days.”

Another area that BOMET has looked to develop and meet customers’ needs is the demand for special lengths, which is a growing sector. “We have found that there is still very little cutting on the construction site – customers like to buy a fixed product,” explains BOMET. “This is another reason why we have invested a lot in automatic cutting machines in recent years, in order to follow this trend and shorten the delivery time to a few days.”

By investing in its machinery BOMET can also be assured of the quality of its products, which is essential when it comes to threaded rod. “Thanks to our qualified and experienced staff we are able to guarantee a good production flow and we can make sure all the threaded rod we produce is in accordance with DIN standards when it comes to minimum and maximum tolerances,” points out BOMET. “In the past there has been a lot of issues within the threaded rod market when it comes to the top angle of the rod and the importance that plays in its quality. According to the norm DIN 976-1 the top angle should be 60 degrees. If you reduce the thread angle the core diameter becomes smaller, but the outer diameter remains the same. This means that a nut can be ripped off the core of the thread relatively easily and can be very dangerous for construction projects. With BOMET, customers can be assured about our quality standard.”

To further ensure the quality of its products, BOMET has recently invested in a new tensile testing machine that can pull up to 1,000kN. The machine enables the company to help verify high-quality steels that are being increasingly used in the wind turbine and high-tech industries. Other developments BOMET has introduced include the recent implementation of its webshop – where stocks and prices can be checked 24/7 – as well as the company introducing sustainable and environmentally friendly packaging. Plus, in Spring 2022, the BOMET UK office will be reactivated – making it easier for UK customers to collect their goods from the depot in Birmingham, without extra import costs and delays at the border.

“We are very proud to be able to produce our products in the very heart of Europe and ensure customers receive high-quality products as and when they need them,” concludes BOMET. “The last two years have shown that strategically it is better to have a source in Europe for products, especially with such unforeseen circumstances that are out of a company’s control. We have seen an increasing number of requests from existing and potential customers over the last 24 months and with sustainability becoming more and more important, companies will continue to weigh up the benefits of importing a container of threaded rods from the other side of the world, especially if they can buy it for the same price from a centrally located European producer.”

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.