Berardi Fasteners is able to offer integrated logistics systems, not only for the easy supply of components, but also as tailor-made projects designed to save customers time and resources.

For over 100 years, Berardi Fasteners has been in the hands of the same family and is now led by the fourth generation – Giovanni Berardi. By constantly enriching its inventory of products, the company has positioned itself as a partner and industrial distributor of excellence – providing technical, commercial and logistical support, which features the most advanced solutions and technologies shared with customers and suppliers in a virtuous supply chain.

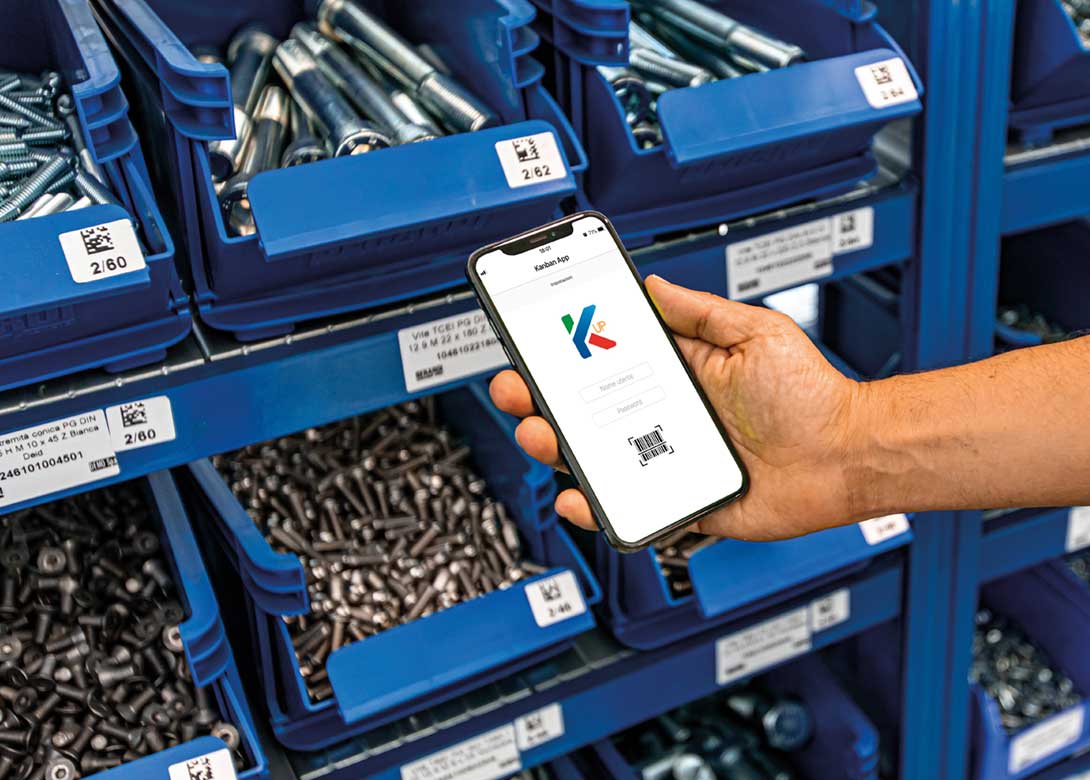

One of Berardi’s main strategies is the development of its integrated logistics services, such as its Kanban and Kanban Up services, which help customers save the time and costs of managing components. “Kanban and Kanban Up are integrated logistics services conceived to sustain our partner companies with constant and measured supplies of fasteners, fittings, clamps, and more,” explains Andrea Destro, Lean manager at Berardi. “These systems are designed specifically for customers and reserved for the Lean supply of C-class items.”

A dedicated 10 member team analyses the procedures and production flows to be improved and uses a collaborative approach to develop the perfect integrated logistics solution. The savings achieved and problem reduction inherent in the management of these materials are the basis for the success of Berardi Fasteners’ logistics solutions. Berardi is able to follow demand fluctuations very closely, ensuring stable supplies that use less warehouse space, and offer professional logistics support all along.

“Fasteners are relatively low price products, but their management is expensive, as the purchasing and logistics departments spend a lot of time procuring the materials,” explains Andrea Destro. “We solve this problem by designing services based on the exact production needs of our clients. We have experience of over 400 logistics installations, which allows us to immediately understand the key points and provide a customised solution for every client, tailor-made on their peculiarities and changing needs.”

EasySelf 24™

Besides Kanban and Kanban Up, Berardi has also implemented the EasySelf 24™ vending machine service, which acts as another step towards Industry 4.0.

This innovative system was conceived to automate materials management, such as PPE, tools, first aid equipment, etc, making every transaction traceable. EasySelf 24 automatically sends notifications, purchase orders, and consumption statistics, allowing for easy online data monitoring – simply, quickly and safely.

“EasySelf 24 is a smart machine that gives its users all the necessary information in order to waste as little time as possible on the management of these products,” mentions Andrea Destro. “It helps users manage materials in minimal space and has the advantage of reducing consumption, as operators are directly responsible for the equipment. The EasySelf 24 machines are highly customisable, with the doors available in different sizes depending on the various sizes of the materials.”

Andrea Destro concludes: “To reach our planned growth, we understand that we must combine the opportunities Industry 4.0 offers with the experience we have gained from one hundred years of corporate activity. Through our Kanban services, and EasySelf 24 vending machines, we are continuing to innovate and this will enable us to further consolidate ourselves in Italy, whilst aiming to expand around the world.”

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.