Würth Industrie Service has been investing in its test laboratory in order to continue to provide absolutely reliable test results of the highest quality – using state of the art technologies.

Würth Industrie Service’s test laboratory is specialised in fastening technology and is accredited for more than 50 test methods conforming to DIN EN ISO/IEC 17025 – enabling it to serve as an official and independent testing station, whilst ensuring maximum product and process quality.

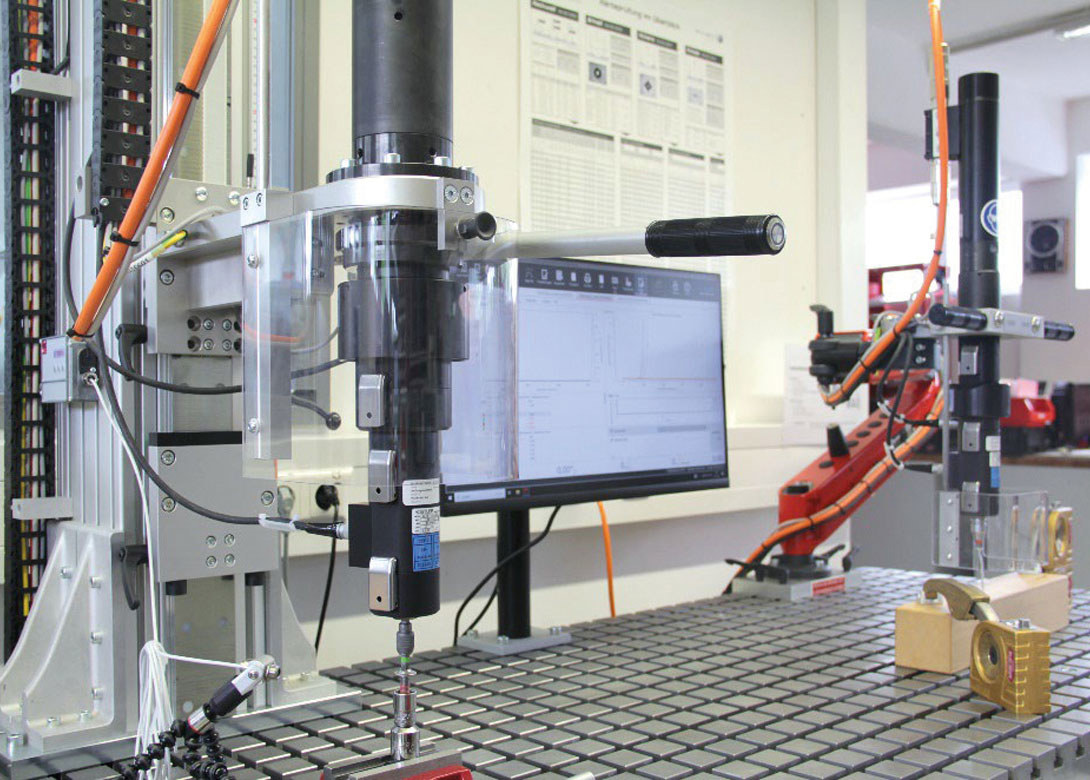

In the area covering 800m2 the highly qualified employees at Würth Industrie Service use state of the art testing devices to ensure seamless quality management. New testing options available include a torsion test bench, scanning electron microscope and adhesive testing technology, with the laboratory experts having their sights firmly set on customer requirements.

With the new torsion test device, customised tests can be carried out on component screw connections with double the torque of 300Nm and with a rotation speed of up to 1,500 rotations per minute. The vertical column test stand also helps to screw in connectors with a weight of up to 500kg vertically in order to determine various parameters like clamping force, breakaway torque and tightening torque. A free-moving tilt arm can be added to the torsion test bench for optimally conducting tests on customer’s components in inclined positions and multiple positions with a single placement.

“With the new test bench, we have even more options for testing fasteners. We can advise our customers more precisely and support them in a better way when faced with challenges in various application scenarios,” explains Sandro Nahm, deputy laboratory manager at Würth Industrie Service GmbH & Co KG.

The company also has the ability to test adhesives, which are increasingly being used in all areas of manufacturing. Based on comparable test series carried out on a separately set-up gluing workstation, two trained employees determine which adhesives are suitable for what purpose – depending on factors that range from quantity of the adhesive and strength of the adhesive connection to load-bearing capacity.

As a comprehensive partner, Würth Industrie Service can also offer its customer a complete package ranging from consultation and testing of adhesives, required auxiliary materials such as more chemicals to recommendations for occupational safety items.

With the new scanning electron microscope, the company is also looking to progress through innovation. The microscope can be used to map the broken and heavily stressed components at nano level, making it possible to detect the smallest of anomalies within the surface quality and specific properties of the fracture structure, such as fatigue striations. This enables detailed statements on the origin of the fracture or the cause of the error to be derived. The chemical composition of the sample can also be determined in the smallest space using a special detector.

As a result of these investments, Würth Industrie Service’s customers benefit from maximum commitment to quality, which also applies to non-Würth parts.

Among the other highlights of the laboratory are the friction testing machine for fasteners – for testing screws up to the size M80; a salt spray chamber for corrosion testing; and a measuring room for measuring complex geometric tolerances – with the latest 3D multi-sensor technology.

“We test fast response times with modern testing devices – just what our customers want,” says Jürgen Bauer, laboratory manager at Würth Industrie Service. “Within Würth Industrie Service, we inspect fasteners for departments like incoming goods, initial sample testing, application consultation and complaint management. We also receive enquiries from all over the world and provide our expertise in quality control, application consulting and product development.”

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.