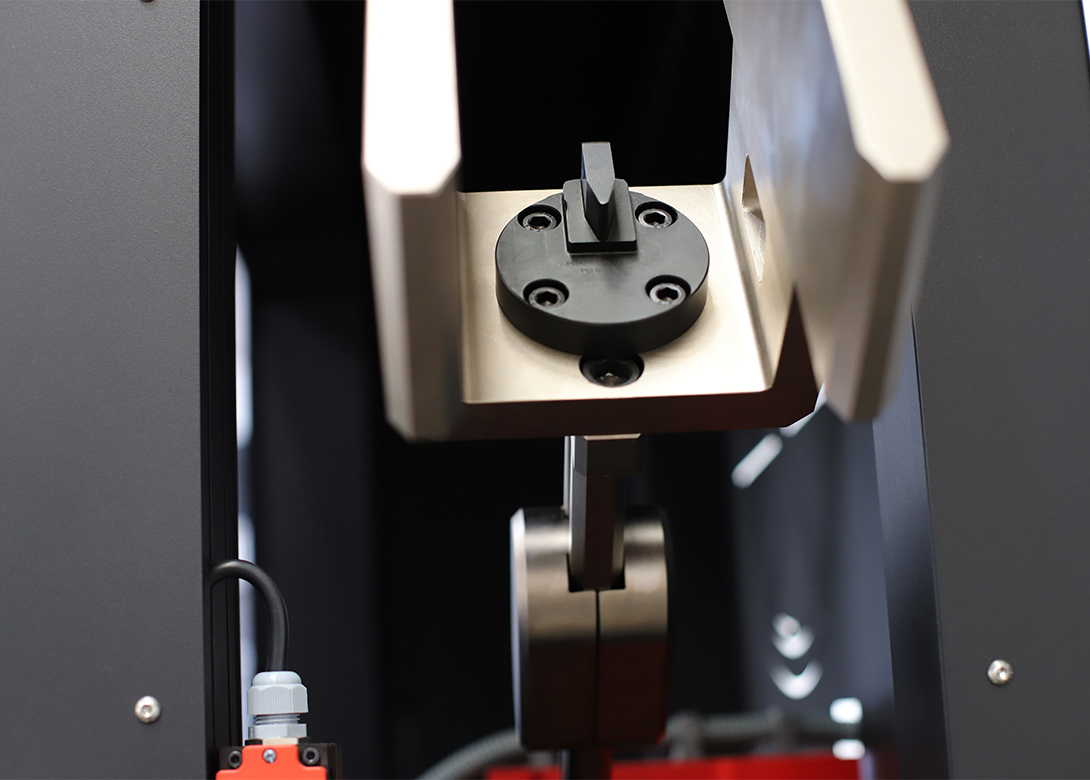

Hoytom S.L has developed a new Charpy/Izod pendulum impact tester for metal testing – HyTT – available in the traditional 300J, 450J and 750J capacity options – making it easy to run precise fast test cycles.

The speed at which the pendulum automatically returns to the starting position; the new automatic centring device; and the ability to quickly start tests by simply closing the door; have sped up the testing process and enabled customers to optimise the number of tests, making them more efficient. This makes the HyTT ideal when speed is critical, such as during low temperature testing. Its touchscreen and data acquisition software also make it easy to use for any user.

The HyTT has been manufactured using rigid and low friction components and meets both EN ISO 148 and ASTM E23 standards for metal testing. Its 0.01J resolution enables tests to be run from 1J to 80% of the full scale according to ASTM E23, without the need to change the hammer.

In addition to its excellent technical characteristics, HyTT features a sliding door opening mechanism that makes it more conformable to position specimens and subsequently collect them after testing.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.