Here Cesar Certini, owner of CERMAC Srl – an Italian testing machine manufacturer – focuses on pendulum impact testing machines and how they can be used to determine the amount of energy absorbed by a material during fracture.

Pendulum impact testing machines are high energy machines that can be used to determine the energy dissipated during fracture of a wide variety of materials, including high strength steels, metals and composites.

A standard pendulum impact testing machine is made up of the following key parts:

There are two types of pendulum impact tests – Izod and Charpy. For the Izod impact test the sample material is held vertically with the notch facing the pendulum. In a Charpy impact test the sample is held in a horizontal position, with the notch facing away from the pendulum. The decision on which method to be used is normally based on the design and testing configuration of the sample.

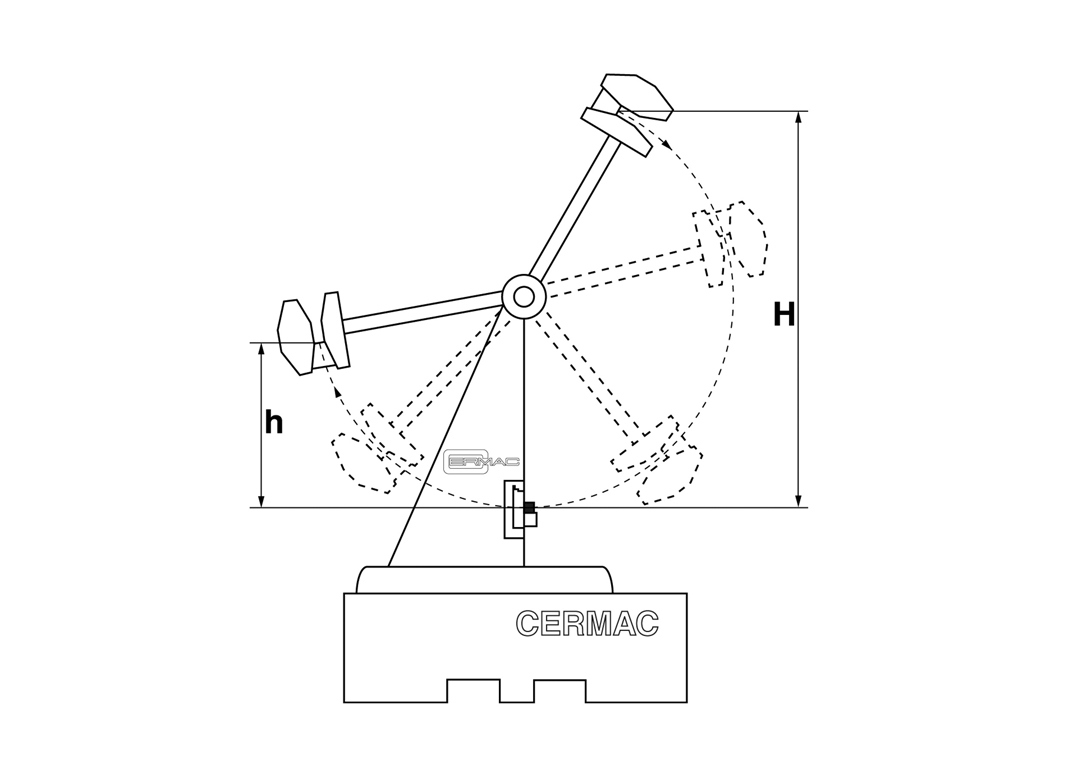

CERMAC focuses on machines that carry out the Charpy impact test, which is very simple to perform. Firstly, the hammer is led to a fixed height (H) and then is released and dropped by gravity. During its fall, the hammer impacts the test piece exactly in the middle and, after fracture, it continues its motion going up to a height lower than the initial one it started at (h).

From this test the absorbed energy can then be calculated: The energy (Ep) of the hammer at the moment in which it hits the test piece is equal to its mass (m) multiplied by the loss of height of the centre of gravity of the hammer (H), while the residual energy (Ef) after impact with the test piece is equal to the mass of the hammer multiplied for the ascent height (h) after the impact.

To obtain the energy absorbed by the specimen, it is sufficient to make the difference between the two energies, the initial and the final one:

Energy absorbed by the test piece = Ep - Ef = m x (H-h)

Until a few decades ago, most of the pendulums in test laboratories had an available energy of 300J, but with the improvement of materials and heat treatments, this energy is sometimes not enough to fracture the test piece. The consequences of such an event are serious from an economic point of view – because they involve the need to recalibrate the machine and often replace the striker.

For this reason, there are pendulums with different energies, suitable for every type of material, such as the JBE series by CERMAC, which is available in versions from 300J up to an energy of 750J. This makes it ideal for testing particularly tough materials, with motorised and semi-automatic models available – working in full compliance with all mandatory safety regulations.

To add to this, CERMAC pendulums are built in such a way as to satisfy a series of characteristics that allow them to comply with international standards (EN ISO 148 and ASTM E23), relating to precise constructive, static and dynamic geometries, which can be certified by any ISO 1725 accredited calibration centre.

Based in Italy, CERMAC is able to supply a wide range of mechanical testing machines to meet all the needs of fastener companies looking to guarantee the quality of their parts. This includes tensile testing machines, pull out testing machines, pendulum testing machines, as well as equipment for high temperature tests, up to 1,000°C.

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.