At the Control trade fair in Stuttgart, Germany, Kistler showcased its wide range of solutions, including its modular inspection, test and measurement solutions for quality control throughout the production process.

Innovations on display included the mobile handheld testing devices in the 5811 family and the new cerTEST 3 test system for torque tools – along with the latest version of the KVC 821 automatic optical testing system that leverages artificial intelligence to minimise scrap.

The KVC 821 testing sysem is ideal as a quality assurance solution in many diverse sectors, ranging from punching and fastening technology to the medtech industry. The KVC 821 makes use of cutting-edge optical measurement technology to capture precise data about dimensional stability, as well as the geometric attributes and surface characteristics of the units under test. Image processing is handled by the KiVision software, while artificial intelligence is utilised to assess the parts. The image processing software, based on deep neural networks, uses anomaly detection to identify the very smallest defects on the surfaces of the tested parts – even those that were previously unknown.

From development to assembly, Kistler explains that complex industrial production processes must include rigorous and efficient quality controls if they are to meet the market’s demands for product quality and transparency. Right from the start of the process chain, therefore, manufacturers need precise measurement data so they can optimise individual process steps and minimise scrap.

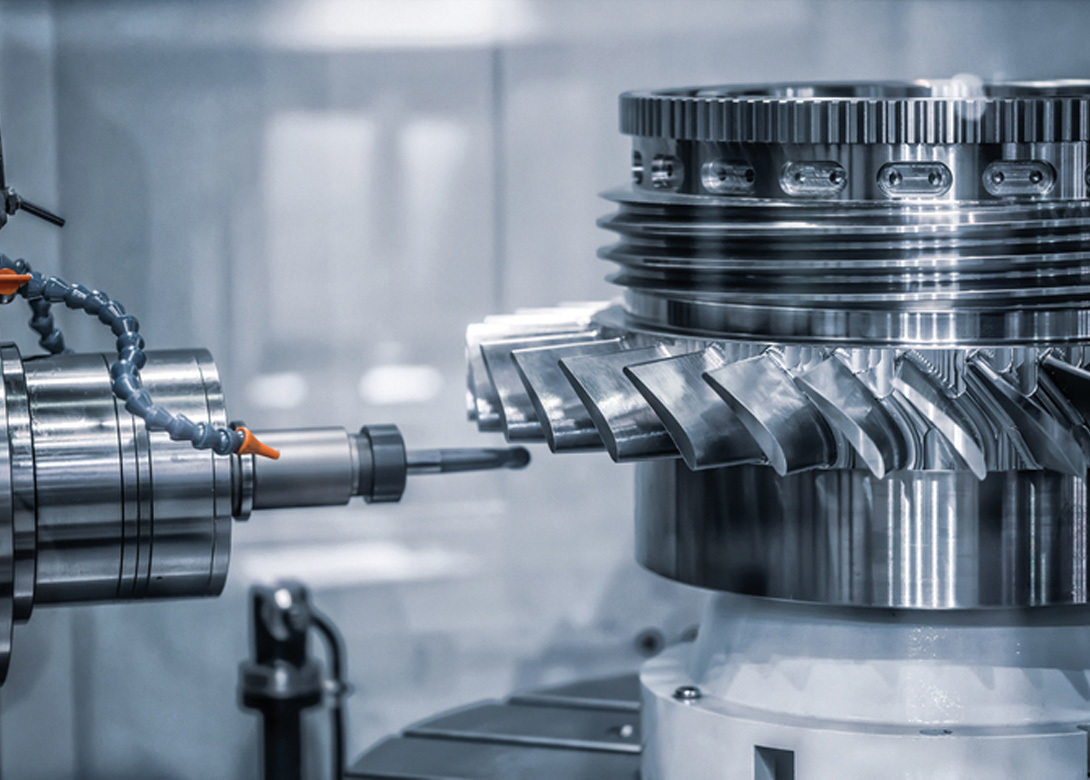

Smart services for CNC machining

Thanks to a collaboration between Productive Machines and the Kistler Group, customers in the machining segment can also now benefit from a full range of performance optimisation services.

“Dynamic stiffness analysis together with force and vibration mapping are the keys to efficiently enhancing CNC machining processes and boosting productivity, in an approach based on simulations, measurements and data analysis,” states Kistler. “Production equipment such as machinery and robots must be maintained in good operating condition to ensure that manufacturing processes are productive, cost-efficient and highly sustainable. In the specific context of modern CNC machining, it is essential to apply, trace and adjust the right electrical and mechanical settings throughout a machine’s lifetime.”

That is why Kistler has announced a partnership with Productive Machines Ltd (UK) covering extended services to optimise machining processes, with a particular focus on milling applications. Productive Machines was founded by Dr Erdem Ozturk, who also led the machining dynamics team at The University of Sheffield Advanced Manufacturing Research Centre (AMRC). The company supports manufacturers with dynamic analyses of CNC machining tools, as well as providing both physical and digital services to optimise NC programs.

The collaboration between Kistler and Productive Machines offers customers a range of value-added services in machine tool analysis. Methods such as dynamic stiffness mapping, cutting force simulations and feed rate scheduling will help to minimise milling force spikes and maximise tool life and performance. Chatter vibrations can also be minimised by a prediction per stability map and an according adaptation of spindle speed. Another focus of the partnership is holistic optimisation of CAM files as an aid to improving productivity and quality.

Insights into the machining process

The physical stage of the service is performed with an impulse hammer – a device containing a piezoelectric force sensor that dynamically excites the structure under test. Resulting vibrations are measured with IEPE accelerometers from Kistler, and a modal analysis then determines the dynamic behaviour of the structure (a milling machine, for example).

The partners are also offering DIGI-FORCE – a new digital service to determine key parameters of a machine set-up based on machine data. Various levels of the DIGI-FORCE service are available, and it can be combined with physical measurements to obtain a complete account of machine and tool capability and performance. The DIGI-FORCE OPT service adds the FRF file data from the machine measurement to the optimised CNC program – so chatter vibrations, tool wear and machine breakdowns can be significantly decreased or even eliminated altogether.

Researchers and production engineers who opt for these services benefit from simulated force levels as the basis for optimising their CNC machining programs – leading not only to enhanced productivity but also reduced effort for R&D and process analysis.

www.kistler.com/GB/en

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.