Founded in 1959, Kistler Group has grown hand-in-hand with its customers to become a market leader for dynamic pressure, force, torque and acceleration measurement technology.

Here we speak to Wilfried Blechmann, head of business field fastening technology at Kistler Group, about how the company works with the fastener industry and the new INSPECTOR torque wrench.

What are the products/services Kistler Group is able to provide to the fastener market?

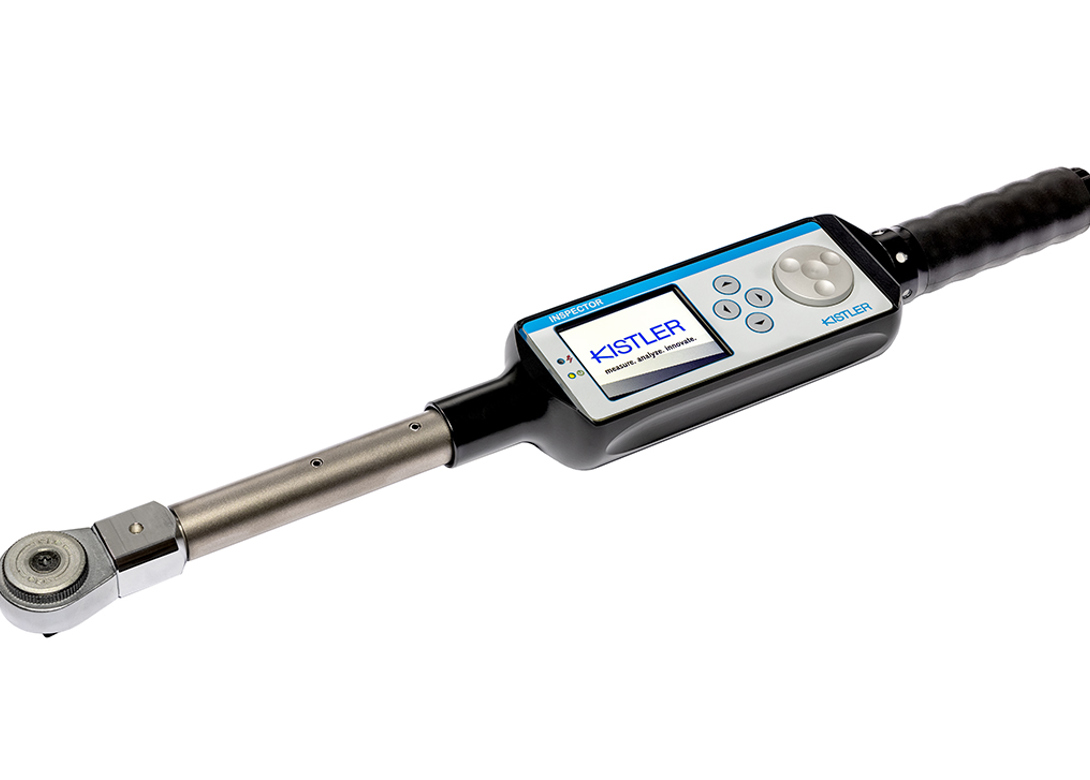

“The portfolio by Kistler includes a wide range of inspection systems for fastening technology and quality assurance. We provide our customers with the sensor technology needed for their specific application and offer a range of services. They include regular calibration checks and testing of torque angle in combination with clamping force. Products such as the new INSPECTOR torque wrench enable our customers to execute process capability testing – compliant with the VDI/VDE guidelines.”

What are the main features and benefits of the new INSPECTOR torque wrench?

“The INSPECTOR torque wrench is equipped with an interface to the software programs CEUS and testXpert and helps to identify errors within the assembly process. It allows us to collect data to determine whether joints have been tightened with the correct torque and whether components are properly connected. We can perform that testing process along the whole assembly line and rule out faulty components that influence the quality of the finished product.

We will continue to develop new features for the INSPECTOR torque wrench and plan on adding additional measuring features to measure the elongation of a bolt via ultrasonic, for example, in the future.”

How can the INSPECTOR torque wrench be used to assist in product development when it comes to fasteners?

“With the INSPECTOR torque wrench our clients can carry out process capability tests on bolted joints for evaluation and documentation of fastening processes under series production conditions. This allows them to run tests and determine correct fastening parameters for their specific components and industrial applications. During this process, all collected data is documented and archived, which meets the growing requirements for process capability, traceability, product liability and efficiency.”

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.