wire® once again underlined its reputation as the ‘must attend’ global wire and trade fair event with exhibitors hailing the show for its high-quality international visitors that were ready to ‘do business’

More than 1,400 exhibitors from 53 countries exhibited in the wire halls, occupying a total of 65,000m2 of exhibition space. Most wire exhibitors came from the major producer countries – Italy, Germany, Turkey, the UK, France, and Spain. There were also exhibitors from outside of Europe, including the USA, India, Taiwan, South Korea and China.

The majority of fastener relevant companies were housed in Hall 15, where approximately 162 exhibitors displayed the latest products in cold and hot forging machinery – for all types of fasteners and complex parts, thread rolling and secondary operations, tooling, materials handling and transfer, inspection and packaging equipment, as well as process monitoring systems and simulation software.

The key players within Hall 15 included Carlo Salvi SpA, CONDAT, Dimac Srl, Hatebur Umformmaschinen AG, National Machinery LLC, Nedschroef Herentals N.V, REGG Inspection Srl, RLS Tooling Ltd, Tecno Impianti Srl, SASPI, Bass GmbH & Co KG, SKAKO Vibration AS, Weighpack WPI Services B.V and SACMA Group.

wire is known as the place for companies to showcase their latest technologies and machines, and this year didn’t disappoint. SACMA Group – with its glass walled stand – presented the progressive header model SP270-WF300°, which package consists of a light WF version, as an alternative of the fully integrated warm forming machines. This 6 dies header will demonstrate to users the benefits of forming parts up to 300°C. The machine also featured the patented ‘S-Feed’ wire feeding system, driven by servomotor, which allows for a very precise and reliable cut-off operation.

Another attraction on SACMA’s stand was the new ‘S-Transfer’ unit – where the transfer is driven by linear motors – allowing operators to set-up and manage all the operations from a touch screen panel SC Matic. The ‘S-Transfer’ also provides additional functions to run difficult parts that require dedicated set-up for a perfect transportation.

“We’ve been doing this show for a number of years now, I personally have been here for 10 years, and I can confidently say that we have been impressed with the business we’ve generated this year,” commented Clive Cross, UK agent for SACMA Group. There has definitely been an increase in the quality of visitors to our stand – with the majority decision makers who are looking to do business.”

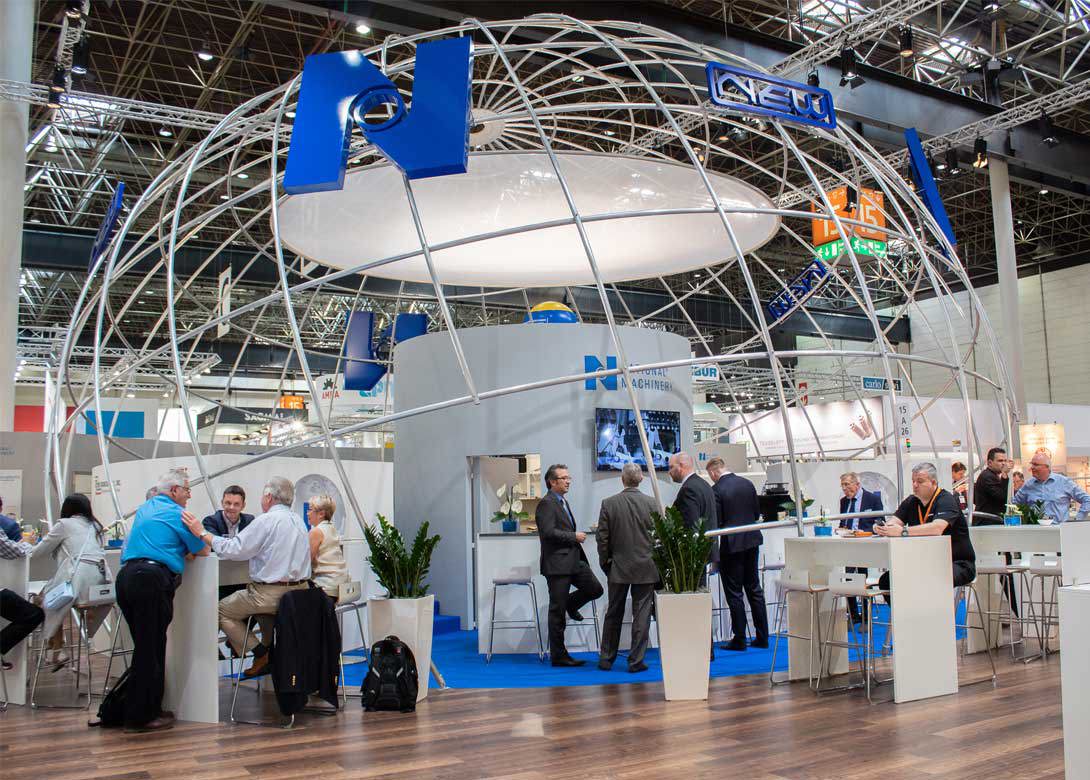

Dominating Hall 15 once again with its impressive dome-like structure was National Machinery. Exhibiting alongside partners Nakashimada Engineering Works Ltd, SMART Machinery Srl and Mectron Engineering, Industry 4.0 was National’s focus, with a dedicated smart factory station equipped with live feeds to off-site and in-booth FORMAX® and SMART threading machines. Customers could view live data from a machine in production to see how that information can be transmitted to other personnel, increasing efficiency and helping to create a ‘smart’ factory. The display showed visitors how useful information from the cold formers and threaders could be easily accessed, displayed and utilised.

Jerry Bupp, marketing director at National Machinery, said: “The 2018 show was the best one in a decade, as the European visitors were looking to add technology to their facilities. The show was very successful with both pending and new orders booked.”

Jerry continued: “The total volume of visitors may have been equal or lower compared to past years, however the quality of those attending was excellent and we appreciated having a full booth the entire show – with demonstrations and discussions. The wire show is always a premier event in

the fastener/forming industry and we look forward to it again in 2020.”

One of the busiest stands in Hall 15 was that of Nedschroef Machinery – also focusing heavily on Industry 4.0. The company was introducing a new concept of ‘smart forming’ to the industry. The basis of the ‘smart forming’ concept is Nedschroef’s revolutionary servo-electro drive technology that the company says makes forming easier and more efficient. It offers much greater repeatability and accuracy while increasing productivity, reducing up to 50% product changeover time – enabling new forming possibilities and more complex part geometries. Moreover, the direct drive transmission of power practically eliminates wear to maximise the lifetime of the machine.

Another striking stand that was bustling with visitors was Hatebur – exhibiting together once again with Carlo Salvi SpA and celebrating the two year anniversary of their partnership, which was announced at wire 2016. An open stand, showcasing Carlo Salvi’s machining capabilities, created a relaxing atmosphere, welcoming visitors to come and do business.

Spanish manufacturer SASPI also had an open stand design, which encouraged visitors to find out more about its vast manufacturing capabilities. For instance, SASPI had a brand new prototype combine pointer, with a completely new design, on display – made mainly for the aerospace industry and highly appreciated for its speed and precision, as well as its high technology and versatility. The pointer can carry out shaving, drilling and broaching at the same time. Also on display was the company’s brand new GV3-20, a heavy-duty thread roller. Fully motorised with patented die block adjustment that, together with other motorisations, makes this machine one of the easiest and quickest machines to set-up. The GV3-20 machine combines the latest technology on the market, and the well known SASPI strength of making a high volume production machine.

Noticeably, tooling and dies companies were well represented this year at the show with the most prominent stands including HEROSLAM S.A.L, Frank Sieber GmbH, M.D.M Srl Special Tools, Polyprofils S.A.S, SFOB S.A.S, and TEMSA – Transformaciones y Estudios Metalurgicos S.A. The latter of which was showcasing its range of dies, punches and pins, tungsten carbide, and auxiliary elements, using a 3D interactive catalogue – attracting visitors to the stand. “The new catalogue caught the attention of many passing visitors and gave us the opportunity to discuss cold forming processes. It proved to be a very good tool to start discussions, without needing preliminary questions. We saw visitors from Germany, Israel, Argentina, Italy, Mexico, the USA and even South Africa,” explained Alberto Gonzalez, area manager at TEMSA.

Also on display this year were a number of fastener cleaning machines from Caber Impianti Srl, MEA Maschinen GmbH, and Enkotec A.S. The latter was showcasing its ENKOclean nail cleaning system – ENKOclean KSN01 – designed for cleaning nails in an inline nail manufacturing production, or as a standalone unit through a drum spiral – with a production speed of up to 2,000 nails per minute. The system washes by high pressure, cascading the nails in a cleaning and corrosion-preventing chemical solution at 60°C.

Fastener relevant companies exhibiting outside Hall 15 included leading specialist in machine technology and tools for cold and warm forming – WAFIOS Umformtechnik GmbH, which was exhibiting for the first time alongside EWMenn GmbH & Co KG after its acquisition in 2015. The company was introducing its AF 141 flat die thread rolling machine to the market for the first time.

“wire and Tube® in Düsseldorf once more proved this year that they are the most important events in the industry worldwide,” said Dr–Ing Uwe-Peter Weigmann, member of the board and spokesperson at WAFIOS AG.

“It never ceases to impress us how these events bring an expert audience and customers from all over the world to the Rhine. For WAFIOS we can report that we posted a multitude of interesting, concrete project talks and closed numerous deals. We look forward to being back in 2020.”

Also exhibiting outside Hall 15 was raw material supplier British Steel – exhibiting for the first time under the British Steel brand. “We were excited to introduce the wire industry to our new brand and take the opportunity to demonstrate how we are investing in our future through our collaboration with FNSteel, which enables us to offer the market an extended product and service range. The show was an extremely busy one for us, reflecting the improved conditions in the market. The stand was consistently busy with customer meetings, and we generated a high-level of new enquiries. The quality and volume of visitor seemed to be an improvement on previous years, and the international range of visitors was impressive – with visitors including those from Europe, North America, Asia and the Middle East,” commented Sophie Day, product marketing manager, wire rod at British Steel.

wire also provided the ideal platform for press conferences on the latest developments within the industry. This included Augustine Kochupampil, CEO at ArcellorMittal Europe, Long Products, presenting the improvements the leading producer of wire rod, and rebar, must make to meet the evolving needs of the industry, such as the modernisation of its wire rod mill in Sosnowiec, Poland. Full completion of the Sosnowiec mill isn’t expected until 2019.

“The Group’s European mills are making major investments in state of the art equipment and this confirms our firm commitment to building a

long-term, sustainable future for bars and rods. We are able to offer complete solutions to our partners and customers such as fastener manufacturers for high-quality products,” said Augustine Kochupampil.

This year’s show was once again held alongside Tube – the international tube trade fair. Both shows saw a combined total of 71,500 trade visitors from more than 134 countries. International visitors accounted for 70% of trade visitors. Organisers also reported 55% of trade visitors voiced their satisfaction at having found new suppliers. 70% of visitors were executives with high decision making authority.

“As trade fair organisers we have once again succeeded in offering the wire, cable and pipe industries a global platform in Düsseldorf as a basis for business,” said Joachim Schäfer, managing director at Messe Düsseldorf GmbH.

Both wire and Tube will once again take place in the Düsseldorf exhibition centre on 30th March – 3rd April 2020.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.