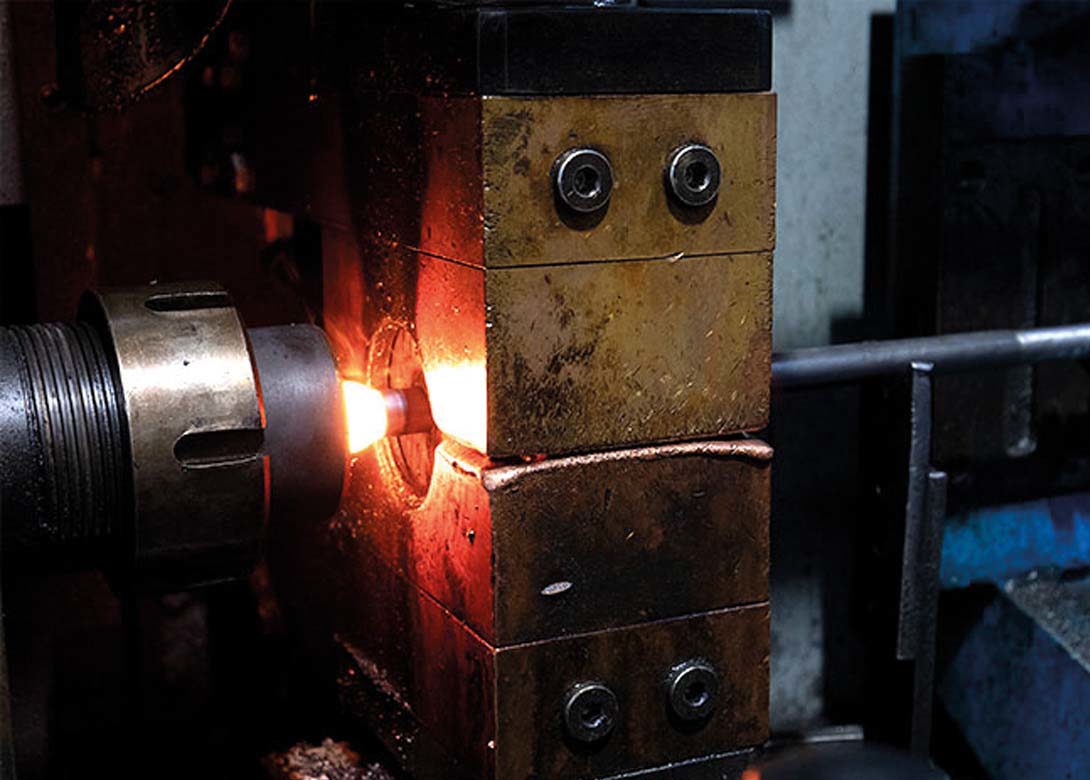

Bontempi Vibo SpA has introduced a new hot forging department at its Rodengo Saiano, Italy site, in order to produce special shapes and profiles that are more articulated and complex than ever before.

Along with a new hot forging technique and highly qualified staff, Vibo now boasts considerable levels of robotics and automation, enabling further flexibility with quick product changes and shorter delivery times. The new investment has also enabled Vibo to expand its product range with a further assortment of stud bolts and screws up to 1,000mm and diameters up to and including M64.

The combination of technical expertise and the new forging line allows Vibo’s specialised team to take care of the entire production process from initial costing to complete development, whilst maintaining consistently high-levels of quality and efficiency that the company has become renowned for.

Additional investments are planned next year for the new hot forging department, aimed at further improving the production process which will significantly reduce lead times and further increase the quality of the final product.

www.vibo.com

Stand:1340

Stand:1340

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.