With the market launch of the HEICO-TEC® tension bolt, the German company HEICO is expanding on its existing assortment of tensioning products. From this point, the manufacturer can offer its customers an even greater variety of products in the field of pre-tensioning technology.

HEICO-TEC® tensioning devices are used wherever bolted joints reach dimensions that make simple pre-tensioning difficult or even impossible. From a nominal size of >M24, the torque required for preloading can no longer be applied by hand. Hydraulic or pneumatic tools are then often used, a time-consuming and expensive solution.

With its HEICO-TEC® tensioning components, HEICO Group says it is offering a clever alternative for pre-tensioning large bolted joints easily, fast and reliably. The special design of the tensioning parts makes this possible.

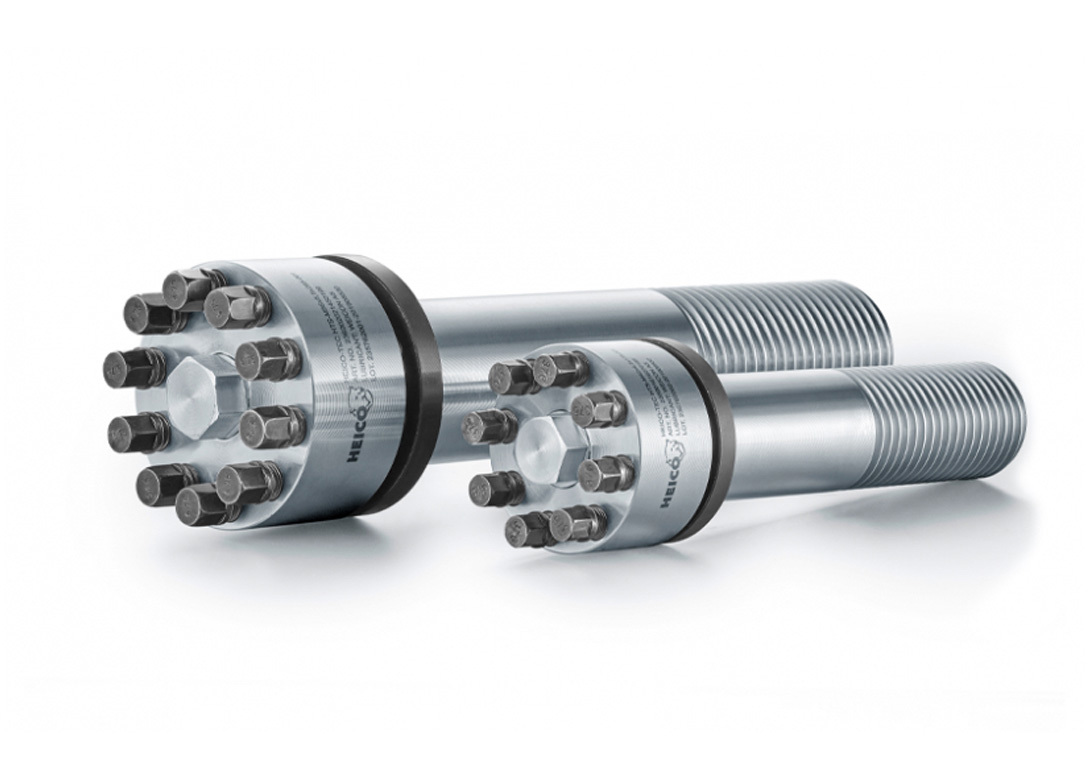

Both HEICO-TEC® tension nuts and the new tension bolts are based on the same functional principle, in which the preload force of a large main thread is distributed over many smaller pressure bolts. Instead of tightening a large nut or bolt with a high preload force, when using tensioning components, the significantly smaller pressure bolts are tightened one after the other in order to achieve the same preload force – making a manual torque wrench is sufficient for tightening.

Tensioning devices are used in many industries, such as in wind turbines, in hydropower applications, in tunneling and mining, as well as in large and heavy machine constructions. Wherever large bolt connections are required, tensioning devices ensure reliable pretensioning with easy and comfortable handling. However, the structural conditions do not always allow the installation of tension nuts. The advantage of the new tension bolt, which will complete the HEICO-TEC® product range, are particularly evident when the installation dimensions are limited. The head and shank of the tension bolt are made from one piece, which allows a significantly slimmer design compared to the tension nut.

The most critical point of every bolt is the transition zone from thread to shank. Therefore, bolts that are tested for fracture must not fail in the transition area between head and shank. This is why the HEICO engineers paid close attention to this critical area and precisely designed this transition accordingly. Despite the smaller head of the bolt, the HEICO-TEC® tension bolts achieve their full load capacity.

As standard, HEICO will offer the new tension bolts in strength Class 8.8 as a replacement for hexagon socket bolts [Allen], sizes M20 – M100. Custom tension bolts can also be designed on customer request.

www.heico-group.com/en/home

Hall: 1 Stand: 1222

Hall: 1 Stand: 1222

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.