By Carl Ghinn, managing director at Fixmart Ltd

In the two years since the BREXIT vote, the UK construction industry has faced a large amount of uncertainty. This has been exacerbated by a lack of skilled workers and cost issues in the supply chain. As a result, many companies have been analysing the build process to find ways to save money whilst improving efficiencies on-site. This is particularly apparent in the installation of services.

In 2015, Amendment 3 to the 17th IET Wiring Regulations stipulated that all escape routes should be fitted with fireproof fixings. The 18th Edition BS 7671:2018, which will be available in July 2018, has extended this to include all fixings throughout a building. Electrical installers will be given a six month transition period to get up to speed with the changes, as from 1st January 2019 it will be a requirement that all electrical installations after this date comply. As well as improving fire safety, the change will force the industry to review the way it uses certain fixings, and encourage innovation within the sector.

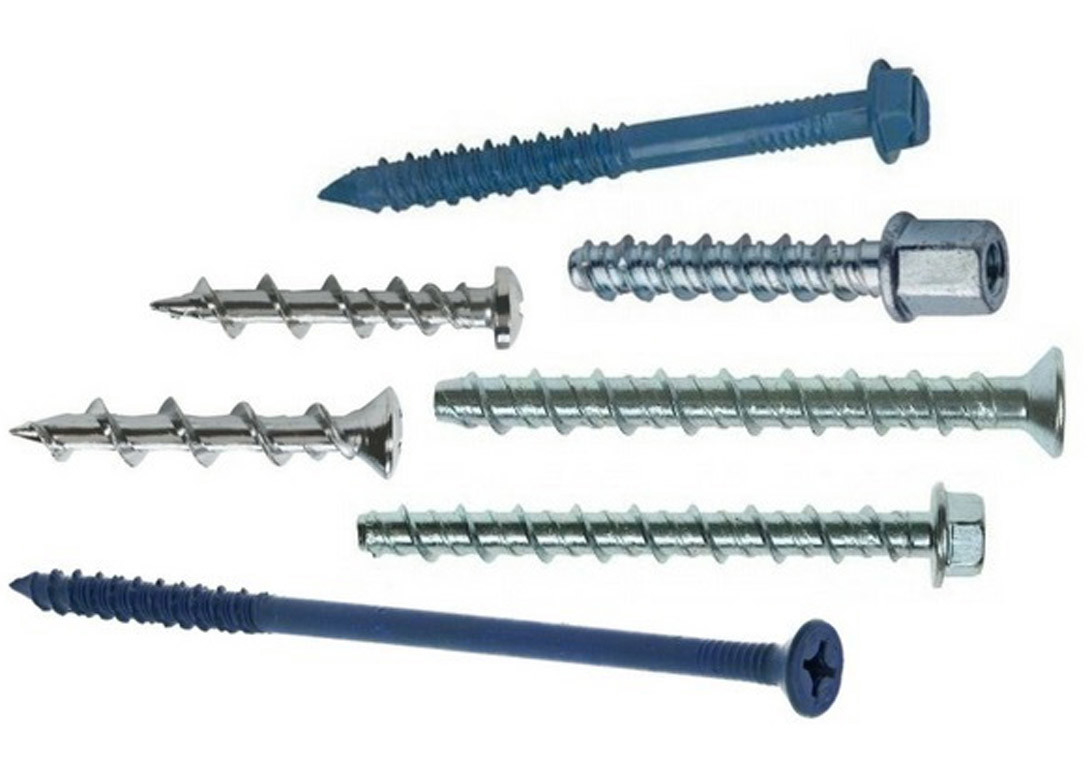

Historically, companies have used wedge anchors for heavy-duty fixings. These are a very cost-effective solution as they are typically cheap to buy and good to use in crumbly substrates, however they are fairly complex to install. Not only do they require significant additional equipment including a drill, hammer and setting tool, they also require extra fixings to secure the brackets, such as bolts and washers.

Another issue is that many workers aren’t trained to correctly use and install them. We are regularly asked to carry out anchor pull tests and as a result, we are increasingly aware of the lack of training when installing wedge anchors as many either fail or underperform in the test. Wedge anchors must be set correctly to ensure they meet the load requirements, and if one anchor fails, the rest will follow and this could have catastrophic consequences. In such circumstances, it is the owner of the company that will be held liable rather than the operative.

As a result, there is an increasing number of companies choosing to use concrete screw anchors as an alternative for heavy-duty loads. In fact, we have seen a year-on-year rise of 198% in concrete screw purchases as there are many benefits to using this alternative.

Speedy installation

Concrete screws are exceptionally simple and quick to install.

As they are drilled directly into the concrete, they don’t require many additional tools or further fixings. This significantly reduces the time it takes to install and, as a result, can be an excellent way of increasing efficiencies on-site especially on time sensitive projects.

Flexible

Another key benefit is the ability to completely remove and reuse the screw. As concrete screws don’t rely on expansion they also allow for fixings to be placed close to edges or to each other. In situations where an unexpected change occurs on-site, concrete screws can dramatically reduce the risk of a costly and time-consuming alteration. This is especially useful where there are multiple trades working in the same space and workers need to be flexible.

Fool proof

Unlike wedge anchors, concrete screws are exceptionally simple to install meaning workers don’t require a lot of training. This particularly helps contractors address the skills shortage where they may have to employ temporary staff that may not be as qualified as permanent workers.

Less dust

Concrete screws require smaller drill holes, compared to wedge anchors, creating less dust. This is increasingly becoming a consideration on-site as contractors focus on protecting workers through both providing the correct PPE and minimising risk.

Cheaper overall

Finally, the combined benefit of all these is that the solution is more cost-effective. In some cases, the actual product may be more expensive, but the fact that it requires less additional equipment, and takes less time to install, can save substantial amounts of money.

Conclusion

To conclude, with the new 18th Edition BS 7671:2018 IET wiring regulations coming into effect in July this year, and an increasing pressure on contractors to find time and cost saving solutions, concrete screws are an excellent and readily available alternative for heavy-duty fixings. At Fixmart, we have tripled our range of concrete fixings in order to support this increase in demand, and would encourage other suppliers to the industry to do the same to fulfil customers’ needs.

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.