Safety requirements protecting people and nature are on the increase in every industry and all aspects of life. As a pioneer in the field of sustainable fixing solutions, fischer now offers the new injection mortar FIS V Zero with a patented formula free from hazard labels.

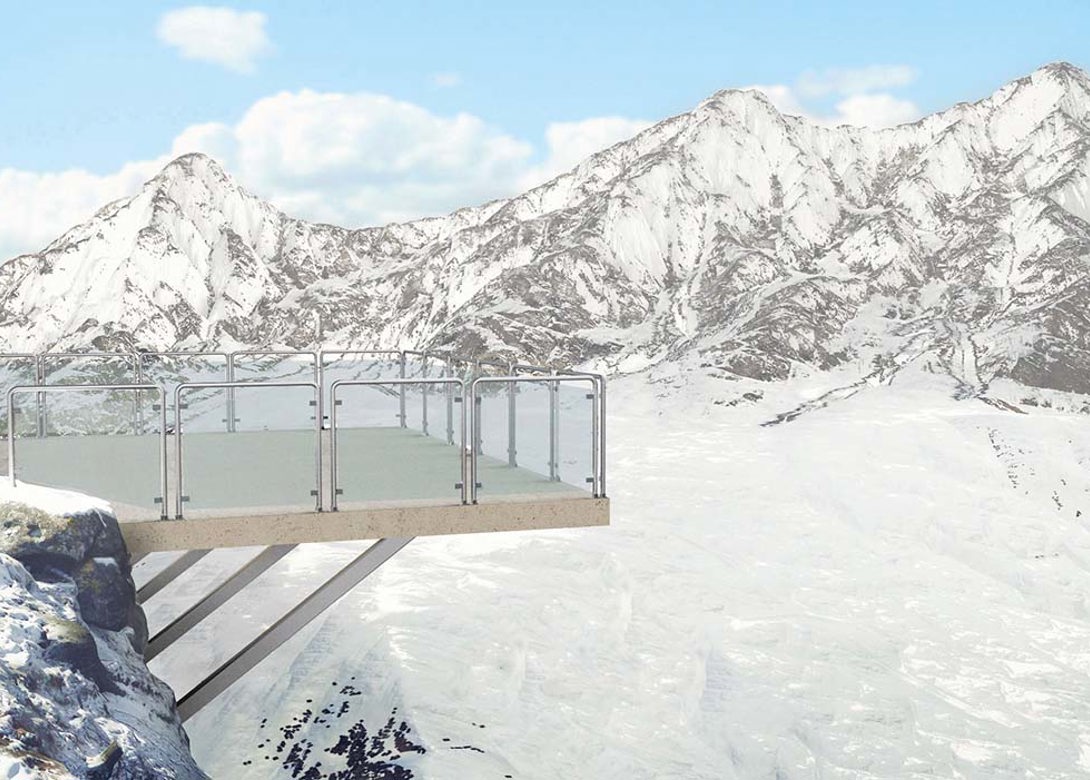

fischer’s new product protects the environment as well as the health of those using it and the buildings it is used in. In doing so, the versatile FIS V Zero achieves the same performance characteristics as other universal mortars. Be it professional applications such as installing railings and post-installed rebar connections or DIY projects such as hammocks – the injection mortar FIS V Zero is suitable for all common chemical fastening applications. The new product combines a secure hold in conventional building materials with the highest health and safety requirements.

The innovative formula of the label free universal mortar guarantees user-friendly and secure use with environmentally friendly application and disposal. Used cartridges can be discarded with the usual household waste, avoiding the costly disposal of hazardous waste. fischer points out the FIS V Zero also requires less administrative work, because unlike other injection mortars, it does not require the shipping and handling of hazardous materials.

Innovative formula protects people and planet

Innovative formula protects people and planet

By replacing dibenzoyl peroxide and other substances classified as environmentally hazardous, sensitising and eye irritating, the FIS V Zero does not require a hazard label and the corresponding safety data sheet. Instead of this peroxide commonly used for radical curing bonded anchors, the product uses environmentally friendly substances and a new, patented curing mechanism, resulting in maximum protection of people and the environment.

Thanks to its innovative formula, the mortar fulfils the highest requirements to maintain clean indoor air quality with VOC content and VOC emissions (Volatile Organic Compounds) as confirmed by the Eurofins Indoor Air Comfort Gold certificate. This makes the universal mortar ideal for closed rooms. The product is furthermore certified in accordance with the Nordic Swan Ecolabel, the official ecolabel of the Nordic countries, which identifies products that are particularly environmentally friendly.

Flexible applications on the construction site

The new universal mortar has a wide range of applications. It has a European Technical Assessment (ETA) for fastenings in concrete (ETA – 20/0572) and all conventional types of masonry (ETA – 21/0267) as well as post installed rebar connections (ETA – 20/0574) and water-filled drill holes.

The universal mortar can also be used in any weather condition. By being simple to use in water-filled drill holes, it can also be installed in various conditions on the construction site. The approved installation temperature of -10°C to 40°C allows the product to be used on the construction site all year round, as well as for flexible applications by various trades. An in-house assessment from fischer has confirmed installation temperatures of up to -15°C.

The FIS V Zero can be processed in the same manner as other injection mortars. The mortar is injected into the cleaned drill hole into which the system component is inserted to fasten the attachment part in concrete or masonry. Options include the anchor rods FIS A and RG M in solid building materials, available in many different diameter versions (M8 to M24 in concrete and M8 to M16 in masonry). Variable anchoring depths allow it to be adapted to the application and load requirement in concrete. There are also internal threaded anchors for applications in concrete and masonry. System components made of electrogalvanised or stainless steel are available for indoor and outdoor applications. Together with the fischer FRA rebar anchors (stainless steel R), the FIS V Zero is ideal for restoration and renovation projects on reinforced concrete buildings.

fischer dispensers allow quick and easy processing of the injection mortar. Upon activating the dispenser, the two separately stored resin and hardener components are mixed and activated in the static mixer. Opened cartridges can be reused. The anchor sleeve FIS HK can additionally be used in perforated construction materials, which guarantees low mortar use with an optimum fit in the chambers of the perforated brick when inserting the anchor rod.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.