In this article Mark Salmon of Independent Fixing Consultants outlines some of the most significant developments in the world of construction fixings over the last few years and suggests how fixing distributors can take best advantage of them.

As usual I’m taking a very personal look at developments in fixings and highlighting those I have found most interesting over the last few years, so I’m not covering every category of fixings nor restricting myself to the actual fixings themselves.

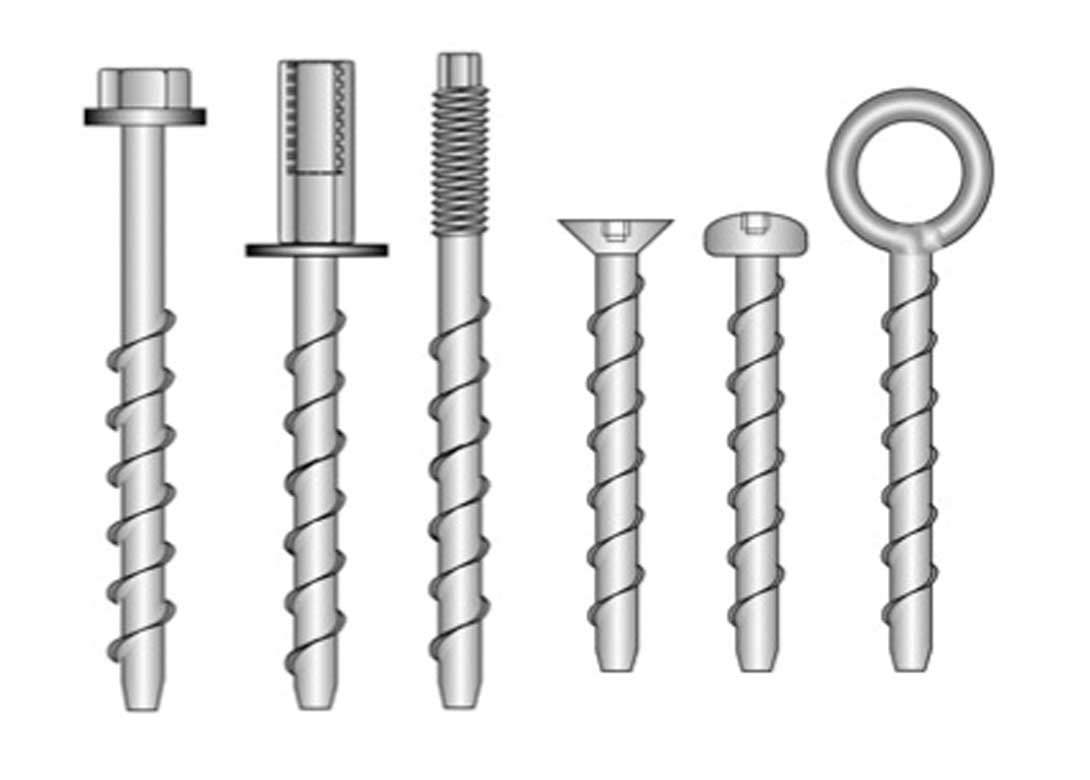

I intend to discuss resin anchors – seemingly the subject of constant development by manufacturers; self-tapping concrete screws, which over the years have established a very useful niche for themselves in construction fixings; as well as dust control, British Standards and one or two other aspects. Although some of the new product developments I’m referring to are specific to one or two manufacturers. I refrain from using brand names – my apologies if this makes tracking them down harder – but I feel it is fairer overall not to be seen to be too partial.

Distributors – how do you cope?

Those of you who have kept up to date with the developments in anchoring technology over the years will realise the subject has become more and more complicated. While product developments are always welcome, bringing as they do benefits in applications, performance, installation or cost – and the introduction of standards like BS 85391 makes anchor usage safer for all concerned – it does mean the job of the fixings distributor has become harder.

To offer your customer the most appropriate anchoring solution for his or her needs, your sales person now needs to be aware of the features and benefits of an ever widening range of products, the range of base materials they may be used in, the limitations on their use, how they should be installed and with what tools. Also, when most applications are safety critical they need to be familiar with all the aspects of anchor selection that are detailed in BS 8539:2012. For those unfamiliar with this standard, it sets out the roles and responsibilities of all stakeholders involved in the use of fixings from initial design to commissioning for manufacturers, distributors, specifiers, contractors, installers and testers. Whilst those listed for distributors appear to be the least onerous it is those of the specifier that a good distributor salesman needs to be aware of to ensure they are not overlooked. The Construction Fixings Association publishes a series of ‘How To…’ guides2 – as part of its ‘8539 Toolkit’ – which summarise responsibilities for key stakeholders and are a good introduction. Complicated as this all may sound, support is at hand and a good manufacturer will offer comprehensive technical support for any distributor handling such applications. The other area that is almost harder for distributors to cope with, as new developments come on stream, is making sure telesales staff are familiar with the products they are selling and in particular the accessories and installation tools needed to go with them.

Dust control

This may sound like a very peripheral area for distributors of fixings but it is a problem for users and an opportunity for distributors. The HSE has placed increasing emphasis on the need for dust control for any workers involved in the cutting or drilling of concrete (among other things) as the very fine dust generated in these processes can cause silicosis.

The HSE’s Construction Information sheet 363 – ‘Construction Dust’ – is a good starting point. High on its list of preferred solutions is “On-tool extraction” followed by “Respiratory protective equipment (RPE)”. Distributors who become familiar with the regulations4 can help their customers by providing suitable equipment in these categories and of course you need to provide them for your own staff who carry out demonstrations on-site. Systems for dust collection during drilling include vacuum attachments for drills that collect the dust as it’s generated using a vacuum cleaner,

which can be separate or an integral part of the drilling machine. Equally useful are shrouds that suck themselves onto the surface being drilled (including brickwork) with a suitably powerful ‘extraction unit’ and collect the dust at source but are not attached to the drilling machine.

Resin anchors My last article, in Issue 103 of Fastener + Fixing Magazine, referred briefly to some of the developments in resin anchoring systems. I will try to make this a little more comprehensive.

Resin anchoring has become the most complicated of all construction fixing types. We are all familiar with the distinction between capsule systems – good for, and limited to, use in concrete – and injection systems with their greater degree of flexibility for use in concrete and masonry, but the range of systems now available is both impressive and bewildering. The formulations of resins range from polyester (cheap and cheerful) and vinylester and hybrid mortars (stronger and more versatile) to epoxies (specialist). The different characteristics range from the different range of temperature they can be installed in and are good for in service; the ability to work in flooded holes; different susceptibility to poor hole cleaning and different rates of curing; while some have been developed to work better in concrete only and others in masonry only.

Installation temperatures and curing times are directly linked. The fact that some formulations can be installed only in temperatures of +5°C or more while others may be installed in temperatures as low as -30°C makes it important that customers are guided carefully in choosing the most appropriate type. Curing times have recently seen useful gains. A typical capsule system for use in concrete might have curing times ranging from 4 hours at -5°C to 10 minutes at +20°C whereas an injection system using a similar formulation could take 24 hours at -5°C to 45 minutes at +20°C with a winter grade available for faster curing, which takes 3 hours at -5°C and 30 minutes at +10°C. One specialist capsule system designed specifically for use in cracked concrete and used with special anchor rods cures in as little as 8 minutes at -5°C and 2 minutes at +20°C.

Usefully the special rods that facilitate the system working in cracked concrete also enable the anchor to be installed in a drilled hole of the same nominal diameter as the anchor rod. Faster curing is obviously an advantage but with injection systems it carries the disadvantage that the time available to insert the anchor and adjust its position (variously called the gel time, open time, working time or setting time) will be shorter and at the upper end of the installation temperature range. If encountered during Spring and Autumn, it may prove difficult if not impossible to insert the anchor rod and the resin may go so stiff in the mixer nozzle that it could require a new nozzle for each fixing.

The fast curing capsule has no such problems of course. On the other hand some applications – like rebar anchoring – benefit from a slower cure giving more time to insert the rods and, in the case of multiple bolt groups, to align rods with multiple holes in the fixture. Slow curing (very slow curing) is one feature of epoxy resins along with minimal shrinkage that is beneficial if a larger hole diameter is used to deliver a larger bond area in a shorter embedment and thus offer higher loads.

Self-tapping screws

Otherwise known as concrete screws, self-tapping screws have become a useful addition to the fixings catalogue. As they cut their own thread in the base material, be it concrete or reasonably hard masonry, they form a secure interlock with the base material providing very strong fixings.

One problem that has afflicted some concrete screws is hydrogen embrittlement. This problem arises if the plating process involved in plating the very high strength steel used to make these fixings is not adequately controlled. The result can be that the heads of the fixings have been known to snap off over night after tightening. Anchors with ETA5 have to satisfy a test to demonstrate they are not prone to this problem. Some manufacturers have recently introduced coatings of zinc flake, which avoids the problem of hydrogen embrittlement while improving corrosion resistance. The improvement is significant in terms of performance in a salt spray test but not so great that they can be specified for long-term use externally. For that usage stainless steel versions are now available. It is always beneficial to ensure that anchors, of any type, have been awarded an ETA but with concrete screws that carries one limitation – they may not be reused. This is because the action of cutting its own thread in the base material inevitably wears the cutting elements ever so slightly meaning they may be harder to insert and eventually lose performance.

Some manufacturers, recognising that many users want to reuse these anchors and that they still have useful performance after several insertions, have introduced the use of a ‘Go – No Go’ gauge, supplied free in the box, which tells the user if the threads have worn below their useful limit and should then be thrown away. The use of the gauge immediately invalidates the ETA for the application in question but if loadings are important then alternative independent certification with reduced loads is available. The fact that manufacturers are prepared to give users the means of saving some money rather than standing on their dignity and saying “You must buy new fixings after a single use” is, I think, a refreshing approach.

This may sound like a very peripheral area for distributors of fixings but it is a problem for users and an opportunity for distributors. The HSE has placed increasing emphasis on the need for dust control for any workers involved in the cutting or drilling of concrete (among other things) as the very fine dust generated in these processes can cause silicosis.

This may sound like a very peripheral area for distributors of fixings but it is a problem for users and an opportunity for distributors. The HSE has placed increasing emphasis on the need for dust control for any workers involved in the cutting or drilling of concrete (among other things) as the very fine dust generated in these processes can cause silicosis.