Finding genuinely effective, quick and lasting anchoring for cracked and non-cracked concrete or hollowcore slabs, as well as in masonry substrates, brick or even timber, can prove to be a challenge for contractors and construction specialists – particularly when considering the growing requirements and increasing creativity of designers and construction engineers. Rawlplug has undertaken this challenge by developing and delivering the all new R-LX line of concrete screw anchors.

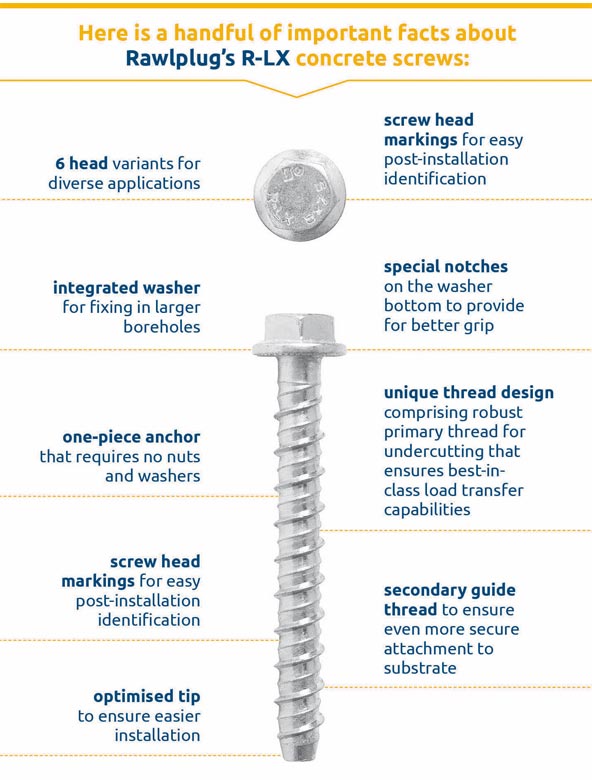

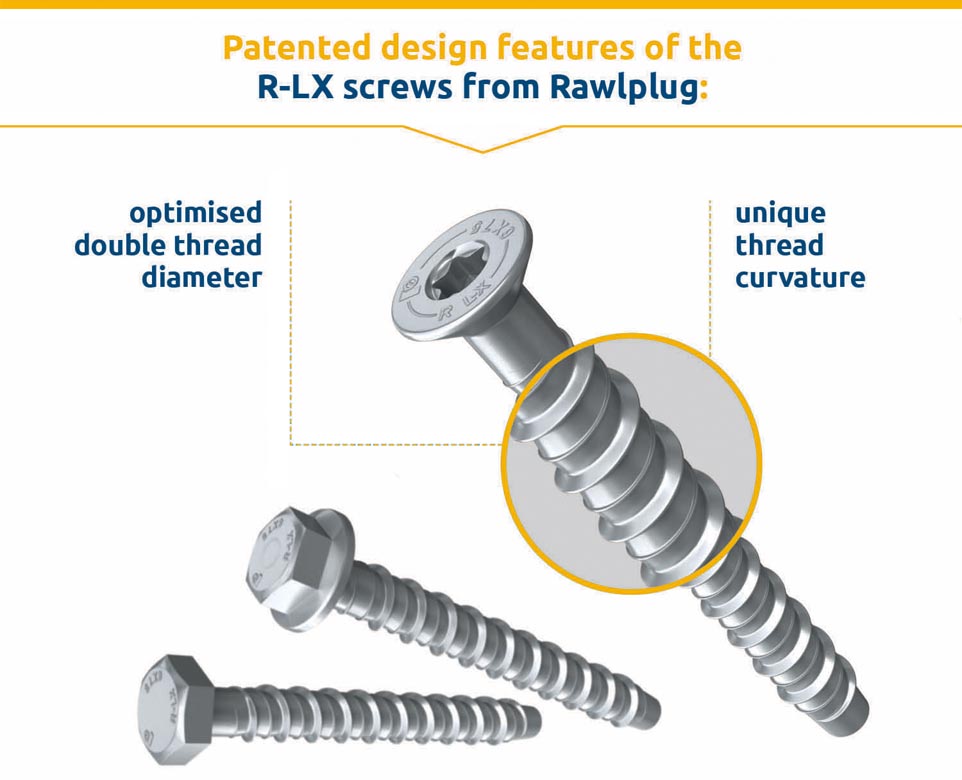

What makes the R-LX concrete screw anchors superior to the throughbolts so popular in many markets? Rawlplug explains that the R-LX concrete screw anchors are functionally unique thanks to the patented and specially designed high-low type thread. The perfect combination of both thread profiles allows it to bite into the material and develop a truly reliable and lasting connection.

The operation of the concrete screws is not based on the expansion principle, instead they undercut the substrate in order to be able to transfer increased loads. The design of the screws enables them to evenly distribute the forces affecting them over the entire thread, even under increased loads. In practice, this means that force distribution in the substrate is analogical to that of elements embedded in concrete and resembles the resistance of reinforcement bars against the substrate. Rawlplug points out the effect is that the R-LX anchors attain the highest available load capacity compared to other anchors in the class.

“We have once again concentrated on innovation, and in doing so, created a truly original solution,” comments Rawlplug. “The R-LX screws feature two separate threads with different pitch heights. The primary thread is responsible for the material undercutting, which helps in distributing the forces affecting it more effectively and decides the anchor’s load capacity. The secondary lower thread enables anchor stabilisation during installation, while also increasing its resistance to shear loads. Both these structural features – the optimum double thread diameter and the special curvature – have been patented, with the product offering unique parameters and unparalleled functionality.”

When the Rawlplug R-LX concrete screw anchors are installed, the borehole material is undercut, and at the same time the undercut grooves are filled with output. The secondary hydration that takes place in the process adds to the load bearing properties of Rawlplug’s screws, as they simply bond to the substrate.

Quality in details

The innovative design of Rawlplug’s R-LX concrete screw anchors has been developed by a team of dedicated experts – practitioners who cooperate on a daily basis to keep track of actual needs of construction professionals. In response to their expectations, the brand’s specialists focused on developing an unprecedented, optimised forging and heat treatment process performed at one of Rawlplug’s European manufacturing plants. The solution owes its innovativeness to the finished product’s high steel Class and the possibility of multiple use, depending on the concrete substrate Class and grain size.

Corrosion resistance – it matters!

Rawlplug states that the process it has designed has additionally allowed it to eliminate the risk of hydrogen embrittlement, which can be a concern for contractors when deciding to use products made of high hardness carbon steel.

“Rawlplug’s R-LX concrete screws are simply immune to hydrogen corrosion,” explains Rawlplug. “Even in the basic version, the product offers high surface hardness parameters, which significantly simplifies and facilitates installation in concrete. Moreover, the core remains flexible enough to avoid cracking while the stresses occurring in installation, dismantling, or operation under load, are transferred.”

Users should also keep in mind that Rawlplug’s R-LX concrete screws have been designed in two variants, both conforming with the requirements of EAD’s Option 1, and come with high-quality zinc electroplated finish or zinc-flake finish – highly resistant to corrosion. The corrosion resistance parameters of the brand’s products have been confirmed in a salt spray chamber test, with a result of 1,500 hours.

Now it’s official

Rawlplug’s R-LX concrete screw anchors meet all the relevant requirements of European Assessment Documents EAD 330232-00-0601, Part 3 (metal anchors for concrete – undercutting anchors) and EAD 330022-00-0601, as well as the guidelines laid down in part VI of ETAG 001.

Spectacular spectrum of applications

Rawlplug’s R-LX concrete screws are intended to be used in a truly wide range of applications – both highly specialised ones, since they offer impressive load transfer capabilities in cracked concrete, matching ETA Option 1 (ETA – 17/0783) requirements (suitability for use in expanded zone), and typical ones that involve multiple point installation and fixing, as per part VI of ETAG 001.

“The specificity of design and characteristics of operation of Rawlplug’s R-LX concrete screws not only ensure increased load capacity, but also make it possible to maintain smaller than required axial and edge spacing, while all advantages of traditional expansion throughbolts are maintained. All these aspects combined means that our anchor is in fact the number one product of choice, especially when facing massive anchoring needs – installing balustrades and railings, gates and fences, shelves, seats and benches in public spaces, steel cable ducts or structures, bumper rails, cladding restraints or subframes.”

Additionally, the R-LX concrete screws require no special tools for installation, and even more importantly –

they can be completely removed when needed without making any damage. The multiple use feature proves particularly invaluable in temporary applications, including formwork, barriers and fencing in construction sites or scaffoldings.

What about installation?

The user simply drills a hole to a diameter slightly smaller than the screw itself by following the clear drill size guidelines provided in the screw product code. A properly prepared hole ensures appropriate screw guiding, while the concrete screw’s main thread will create precise undercutting of the substrate material as it is screwed in.

The R-LX line is very extensive, encompassing even highly specific requirements and satisfying the needs of professionals from all construction segments. The R-LX line is available with as many as six different head variations – hexagonal version with integrated washer, countersunk version for flush installation, internally threaded socket version, threaded rod version, cylinder head version and hexagonal version without integrated washer for temporary fixing. Additionally, each variant covers sizes from 5mm to 14mm and lengths of up to 200mm.

Reliability and trust

“The R-LX concrete screw is a genuine combination of state of the art technology and 100 year experience in product development. It is the most highly advanced solution ensuring impressive use properties and efficiency. It is also not without relevance that it comes with a package of complementary services from Rawlplug’s portfolio, starting from technical consulting and specialised training, to comprehensive documentation.”

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.