By Dr Ulrich Bourgund, chairman, Construction Fixings Europe

This article looks at the importance and benefits of the ETA route to CE Marking for fastener manufacturers and end users of construction products.

Though being small in size, the importance of fasteners for the safety of construction is widely understood. Therefore, it is obvious that major changes to the CPR (Construction Product Regulation), as the legal framework for construction products in Europe, will substantially impact the economics of the industry as well as the safety level of structures.

Though being small in size, the importance of fasteners for the safety of construction is widely understood. Therefore, it is obvious that major changes to the CPR (Construction Product Regulation), as the legal framework for construction products in Europe, will substantially impact the economics of the industry as well as the safety level of structures.

Fastening technology products are widely used in construction and play a major role for the functionality and safety of constructions. Fasteners are used across a wide range of construction applications such as tunnel construction, insulation, façades, ceiling and roof substructures, high steel railings, roofing, as well as bridge construction, which also demonstrates the huge impact on the productivity in this area.

In any case it is easy to imagine what happens if the products in the respective application fail. Transparent safety level and reliable installation are vital for constructions. Major accidents over recent years around the world have clearly shown that this should not be taken for granted and requires continuous focus and a reliable and solid basis.

Options to generate harmonised technical European documents

To arrive at a balanced level of costs and appropriate safety in construction, standards (hEN) have been developed over many years. Additionally, some years ago the concept of European Technical Assessment (ETA) was developed to respond to applications in a more agile fashion, which was well received by many stakeholders in construction. The ETA identifies performance data for products for a specific set of applications and intended use cases, such as earthquake loading or fire – depending on what the applications are subjected to. The basis for issuing an ETA is the EAD (European Assessment Document), which is a document generated by the European Organisation for Technical Assessment (EOTA) for relevant parameters identified in the CPR as basic requirements for construction works – also known as Basic Work Requirements (BWR) in the EAD.

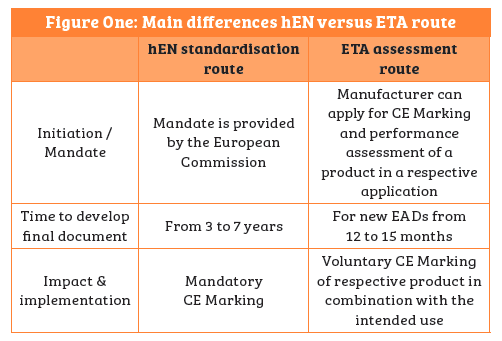

In Figure One the main differences between the hEN route and the ETA route are identified. It is obvious that the ETA route is by far more attractive for small and mid-size companies, apart from just the speed of development.

The development in Europe and worldwide

Over the last few years, the European harmonised documents (ETAs, EAD, hEN) have accelerated the technical development in fastening technology in Europe and many other countries. In some countries outside of Europe these documents are accepted even as reference documents directly. 2,800 ETAs in the scope of fastening technology in concrete and masonry have been granted for many companies in and outside Europe.

Over the last few years, the European harmonised documents (ETAs, EAD, hEN) have accelerated the technical development in fastening technology in Europe and many other countries. In some countries outside of Europe these documents are accepted even as reference documents directly. 2,800 ETAs in the scope of fastening technology in concrete and masonry have been granted for many companies in and outside Europe.

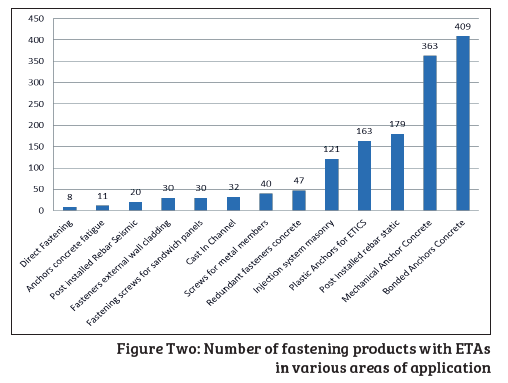

One of the main intentions of the European Commission (EC) during the development of the CPR was to enhance and strengthen the common market. A common market requires transparent rules for identification of performance data for products in specific applications. The performance data for fastening products via the ETA route covers more than 54 areas of application. The most important ones are displayed in Figure Two. Bonded anchors in concrete show the largest number of ETAs among the 54 applications.

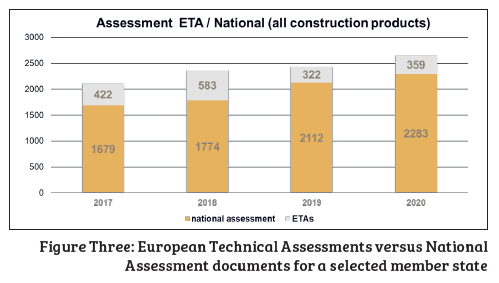

Further analysis of available data from various member states indicates that the level of European technical harmonisation still has potential to grow substantially. As an example, Figure Three shows the number of European Technical Assessments for all construction products versus National Assessment documents for one member state. Quite surprisingly the number of European documents is only on the level of 10% of the national documents, which clearly indicates the level of upside potential for technical harmonisation.

Further analysis of available data from various member states indicates that the level of European technical harmonisation still has potential to grow substantially. As an example, Figure Three shows the number of European Technical Assessments for all construction products versus National Assessment documents for one member state. Quite surprisingly the number of European documents is only on the level of 10% of the national documents, which clearly indicates the level of upside potential for technical harmonisation.

Important aspects from the industry perspective

The wide recognition and dynamics of the ETA route clearly indicate that this concept substantially supports the further development of the common market as intended by the EC. The great importance of the ETA route for the construction industry can be described in six essential dimensions:

Opportunities and risks for future revisions of the CPR

From the fastening industry, as well as from the customer point of view, the legal framework of the previous CPD and actual CPR has triggered quite some dynamics. New products and new applications have been developed continuously to an extent that the range of applicability was dramatically increased and at the same time the performance of the fastening products have nearly doubled in some areas. The investment of the industry has led to a clear leadership position of the European fastening industry in the world.

To keep up the momentum, and to enhance the European harmonisation process, there are still some opportunities that should be considered in the revision process of the European Commission. These include:

Of course, next to the opportunities typically there are also risks associated with the revision of the CPR. The current effort to run the EAD/ETA process must stay lean and efficient, no additional efforts or new formal burdens should be requested from the industrial stakeholders and any slowdown of the speed must be avoided. These dimensions, as well as the retention of the confidentiality during the EAD development for new products and/or new applications, are vital for the acceptance of the overall process by small and medium size manufacturers.

The transition from the current CPR to a revised CPR must also be managed carefully. The transition from the CPD to the CPR is now less than 10 years old and it took years to implement this with still some elements from the CPD times not yet fully transferred. Therefore, the implementation of a revised CPR should keep in mind that a meaningful and reasonably short transition period is important. This aspect should be developed under the guidance of cost minimisation.

The legal framework for construction products is discussed and analysed with respect to performance identification of products in the respective application. Future work for the revision of the current CPR should consider the strength and successes of the current system and eliminate the obvious weaknesses. The efforts, efficiency, and the costs related to the development of harmonised European documents, should be kept on the current level, otherwise there is a considerable risk that the European harmonisation will not further develop and manufacturers will go back to national solutions wherever possible.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.