fischer – committed to its values and people

27 January 2017

fischer is synonymous with innovative fixing solutions and has established itself as a key brand in the global fixing industry. A major factor in this continued success is its three main values – accountability, reliability and innovation, as well as crucially its commitment to its people.

Aprime example of fischer’s investment in its employees is the recent appointment of Johannes Konrad as managing director sales and marketing international. Having joined the company in 2005, Johannes has progressed through the fischer organisation thanks to the continued support and guidance offered by the company.

“The success of any business always depends on the people working in it,” comments Johannes. “The crucial factor is how well trained they are, as well as how motivated they are. Thanks to the ‘lifelong learning’ scheme in place at fischer, every employee can develop their capabilities and contribute proactively to the success of fischer.”

A symbol of fischer’s dedication to its employees is the Klaus Fischer building centre – at its headquarters in Waldachtal, Germany – where the company offers mainstream training and education, helping to support personal development of employees.

“There is an unwavering commitment to the employees at fischer and although we are a big company there is a family feel within the organisation,” notes Johannes. “We have a gym at our headquarters with all the latest machinery, as well as a restaurant that offers a selection of high calibre meals at discounted prices. These are just a few added touches that shows the employees are number one in the company. It also adds to the family feeling and how we work together. This is what makes us better than other companies and what will also enable us to continue to increase our turnover.”

Reliable distribution and service

With 46 national companies in 34 countries, as well as an extensive product range of key fixing solutions, fischer can guarantee a reliable service whilst distributing to different segments and through different channels – focusing on retailers and the DIY market, including key project accounts. To stay close to its customers fischer has production sites in important markets, such as Argentina, Brazil, China, Italy, the Czech Republic, the USA, and three separate sites in Germany.

fischer uses benchmarking and has adopted the Kaizen philosophy across all its production sites and departments – production, sales and administration. This helps give a clear view and transparency on what is happening in production and guarantees best practice. “Our production network also collaborates intensively on an international basis,” mentions Johannes. “This helps ensure each site is delivering the right product, in technical perfection, for a wide range of customers – ensuring a consistent product and service.”

A big advantage of being close to the customers is fischer can also monitor the habits and needs of different markets, which can vary significantly. “Having a presence in different markets means you can better understand the trends of those markets,” explains Johannes. “For example, in Latin America there is a mix between inch and metric systems dependent on the individual countries. In southern European countries, we sell nylon plugs with screws, whereas in Germany they predominately buy the products individually. It is only by having a presence in these key markets you can provide the products that customers need.”

fischer has its own ‘road map’ for the future and has a clear strategy on where it establishes new subsidiaries. This is based on numerous elements, as well as macro-economic factors. For countries where it doesn’t have a direct presence, fischer works with distribution partners. “Thanks to our subsidiaries and partners we have seen continued turnover growth over the last five years,” points out Johannes. “Having a close working relationship with customers also enables us to understand their needs and requirements regarding new products.”

DUOPOWER

Innovation at the foundation

Another key pillar in fischer’s success is its vast range of fixing products, as well as its total commitment to innovation. fischer has been known for innovation since its foundation in 1948 by Professor Artur Fischer. The company holds numerous patents and has a total range of over 14,000 products – meaning it can provide solutions for almost every fixing challenge.

“The best innovation is a simple product everyone needs,” mentions Johannes. “Innovations enable you to be a step ahead of your competition and is a key driver for market development. Our target is to have unique products that offer solutions to multiple problems.”

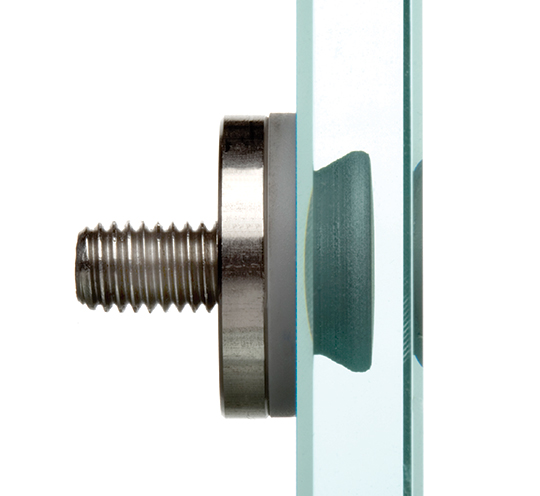

Recent examples of fischer’s innovative solutions include the ACT system, as well as the DUOPOWER range. The ACT system (Advanced Curtain wall Technique) is an innovative, high-quality, all inclusive system for fixing ventilated claddings. The ACT enables the use of natural stone façade panels from 2mm in thickness and glass panes ESG and TVG from 6mm thickness. It also offers free positioning of the anchor anywhere on the rear side of the panel and easy replacement of all or individual panels.

“The fischer ACT system uses undercut technology, combined with a FZP II fischer zykon panel anchor, which means there are no visible fixing elements at the joint,” explains Johannes. “The ACT system opens up the way for effortless and cost-efficient design of attractive, complex designs. It is already a very important system in Asia and the Middle East and we will continue to grow its markets in the future.”

The DUOPOWER range is a new generation of plug that consists of two different materials using 2K injection moulding. It is suitable for pre-positioned and push through installation. The combination of the two materials, and the multiple functional abilities, extend the range of applications the DUOPOWER can be used in, including additional materials with top loads.

“The fischer DUOPOWER expands in concrete and solid masonry, folds in perforated masonry and folds or knots in board materials,” adds Johannes. “These features make it the most talented all rounder among the general fixings and open the door for users to a completely new performance class.”

Ensuring accountability

Thanks to the collaboration of fischer’s high calibre production sites the company can reliably provide high-quality products around the world – such as its full range of high performance steel anchors, chemical steel anchors, chemical fixings, installations systems, sanitary fixings, electrical fixings, insulation fixings, adhesives, and a wide variety of screws.

“Our aim is to offer a complete range of high-quality solutions and improve the value chain of the customers,” states Johannes. “In many markets price is under focus, but it is important that customers also consider the total cost of an application – reliability, safety and security are key aspects. Having the wrong product in the wrong application can lead to serious failures and potentially high repair costs.”

Johannes continues: “Through our fischer consulting division we can work with customers to ensure the most effective product for the installation is used – providing first class products that are also the most effective for life cycle costs and the value chain. Our technicians and engineers have a huge amount of experience and knowledge and can work with customers to guarantee quality installations.”

Another important factor for quality is certification – with European Technical Assessments becoming essential in the market. “Ensuring that you have all the relevant certifications and standards is very important in the fixing market,” explains Johannes. “At fischer we have a complete range and we are always leading the way in the latest accreditations.”

Johannes Konrad started working with fischer in October 2005 as part of a cooperative university course on industrial engineering, which involved alternating between three months of studying at university and three months of training at the company.

Johannes Konrad started working with fischer in October 2005 as part of a cooperative university course on industrial engineering, which involved alternating between three months of studying at university and three months of training at the company.

After graduating in 2008, Johannes started with fischer as the assistant to the chairman of the executive board, before being responsible for price management in a six month role. At the beginning of 2010 Johannes became the managing director at fischer Mexico, which at the time was one of the youngest sales and distribution subsidiaries – having been founded in 2006. Moving to Mexico gave Johannes a new experience in language, responsibility, culture and surroundings.

“Going to Mexico was completely different and was a big step for me personally,” says Johannes. “Even from a market perspective it was different because at the time fischer was not well known in the market. We therefore focused on the strengths of the products and their high-quality. We worked with planners, structural engineers and construction companies and explained the benefits of fischer and step-by-step we established the brand within Mexico.”

Johannes worked at fischer Mexico until May 2012 when he moved to fischer Italy to again become managing director. As the biggest foreign subsidiary in terms of turnover and employees, fischer Italy also included production and an R&D department.

In July 2015 Johannes moved back to fischer’s headquarters – as divisional managing director – with responsibility for central sales, internal sales functions, international key account management, export business, product management, as well as training. At the beginning of 2016 he became regional managing director of Spain and Portugal and both North and South America. Finally, at the end of 2016, he was appointed managing director sales and marketing – international.

Johannes Konrad started working with fischer in October 2005 as part of a cooperative university course on industrial engineering, which involved alternating between three months of studying at university and three months of training at the company.