Approximately 20,000 fischer undercut anchors FZP II T PA provided a secure and concealed fastening of the SwissPearl fibre cement panels on the new Delta House of Delta Holding in Belgrade, Serbia. The fixing solution combines a high-quality look with simple installation and a permanent, firm hold. An additional 8,000 fischer FBN II bolt anchors were also used to anchor the façade substructure in concrete.

The new headquarters of Delta Holding now includes an office building that was completed between 2019 and July 2021. Fibre cement panels provide a modern and distinguished look to the building’s rear ventilated façade. Centroprojekt d.o.o from Belgrade was the planning and engineering office responsible for the project, with the Belgrade construction companies Energoprojekt Visokogradnja A.D. and Dma Koping d.o.o. also involved.

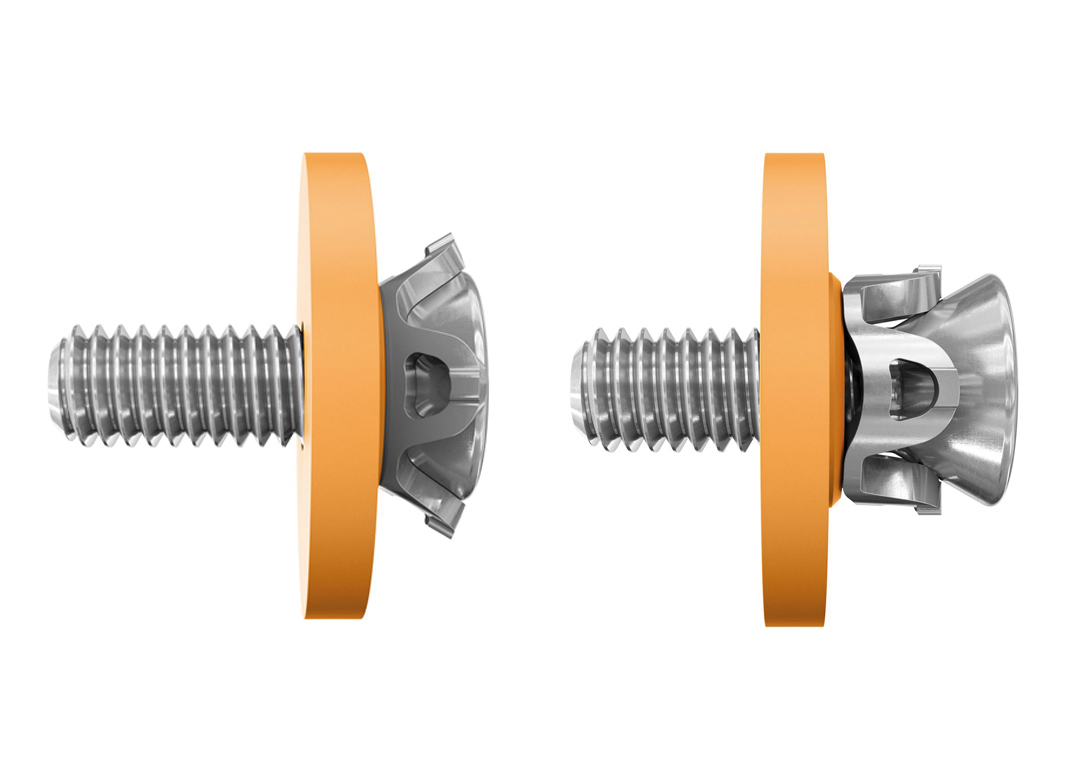

fischer undercut anchors allowed the façade panels to be securely anchored without being visible from the exterior. The undercut anchors provide the building with a harmonious look while enabling simple and quick installation. The FZP II T PA version was used on the project. This fischer Zykon panel anchor is particularly suitable for concealed fastenings of thin fibre cement façade panels and is therefore especially well suited. The fischer FZP II was used in versions FZP II 11 x 5 M6/T/11 PA and FZP II 11 x 5 M6/T/13 PA.

“Rivets and screws tend to be visible when fastening fibre cement panels to façades. This isn’t the case with our Zykon panel anchor FZP II T PA, as the fastening points on the external façade panel are concealed,” says Alen Ilic, technical consultant at the Austrian subsidiary of the fischer Group of Companies. “This enables form-fit fastening without expansion pressure in the conical undercut drill hole. Thanks to its short geometry and additional technical features, the FZP II T PA can be used in thin panels with a thickness of 8mm and up.”

The anchor was used with an embedment depth of 5mm in fibre cement panels by SwissPearl measuring approximately 8mm. By placing the anchor on the reverse side of the panel using undercut technology, the ideal static position can be selected, which prevents the fibre cement panels from deflecting. Together with the anchor’s optimum static fastening, the form-fit and expansion-free anchorage provides high retention forces and allows large panel formats to be used.

The fischer undercut drill FZPB 11T CNC-DIA from fischer’s all-in-one system was used to fasten the rear-ventilated façade during the drilling operation with CNC drilling machines. They guarantee optimal cutting behaviour thanks to polycrystalline diamonds. As a component of the fischer FZP II undercut anchor approval, they are suitable for drilling in panel materials (HPL, fibre cement, etc) using the dry drilling method.

The stainless steel fischer bolt anchor FBN II 12/10 was used in order to securely transfer the loads of the façade substructure into the concrete supporting structure. The heavy-duty anchor allows fastenings to be carried out with a high degree of economic efficiency, while its long thread and two anchoring depths allow a flexible range of applications.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.