In July 2023, Dr Bill Eccles of Bolt Science presented a paper titled: ‘The Goldilocks Zone and the Coefficient of Friction of Threaded Fasteners’. Here, Bill summarises the paper while also adding some background.

When a nut is tightened, the bolt is stretched and resisted by a tensile force within the bolt – this is known as the preload. This preload is triggered by a clamp force that pushes the joint plates together and, in most applications, it is the clamp force acting on the joint interface that is the critical parameter.

There are currently no low-cost means of measuring or controlling the clamp force, so some other easily measurable quantity is needed – controlling the torque value applied to the nut being the most popular approach.

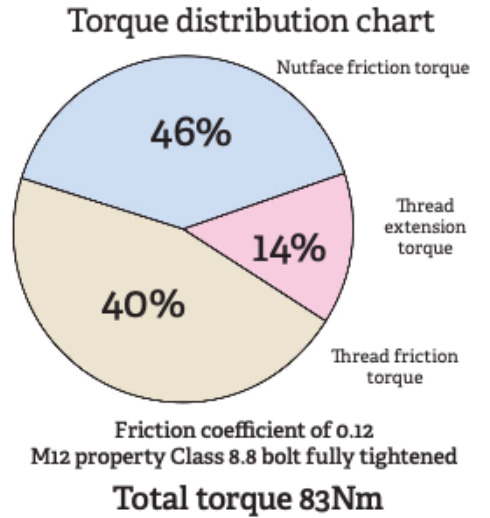

Most of the torque that is applied when tightening a nut is used in overcoming friction. The pie chart shows the case for a M12 property Class 8.8 bolt being fully tightened with the friction coefficient being 0.12. The torque value is very specific to the coefficient of friction, as friction is needed since otherwise the nut would spin off when the socket was removed following tightening.

When a nut is tightened, besides the tensile stress, the bolt is also subjected to torsion. This arises from the thread friction torque and the torque that is needed to stretch the bolt. Accordingly, the higher the thread friction, the higher the torsion in the bolt will be.

Yielding of the bolt is a consequence of the combined effects from the tensile and torsional stresses. The effect of a high thread friction is to lower the tensile stress present in the bolt at yield, as it is from the tensile stress that the preload arises. Consequently, a high friction value reduces the maximum preload that can be achieved.

Although friction can be controlled, to some degree, by the use of wet or dry lubricants, some amount of scatter still occurs. For a given percentage utilisation of the strength of the bolt material, a lower friction value will produce a higher preload. This is due to the reduced torsion being present with a lower friction value. Therefore, from a tightening aspect, a low friction value is desirable since it will allow a higher preload to be achievable at a low torque value.

For more information on this topic and other bolt related challenges visit www.boltscience.com

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.