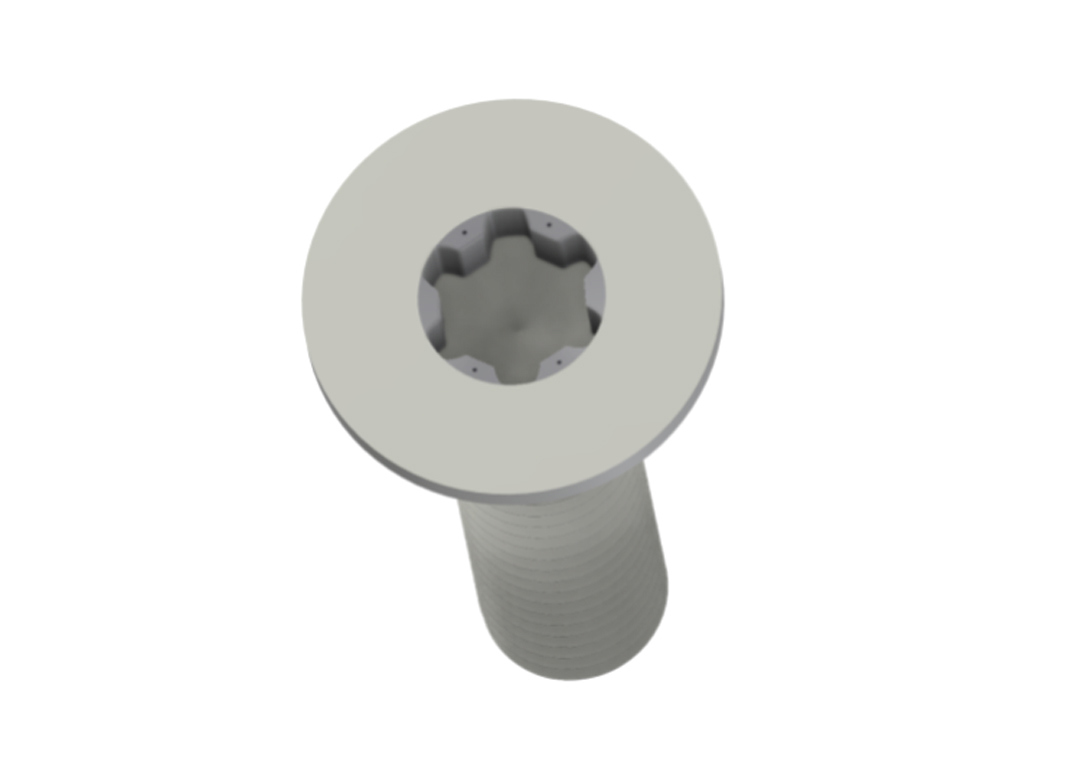

The TORX® family started life back in 1967 with the original TORX® patent. From this humble beginning, this revolutionary drive system has continually expanded its offerings with ongoing improvements and many new design variants to accommodate a wide range of industry needs. Today, the main family members include TORX®, TORX Plus®, and TORX® Paralobe™.

In the aerospace market, TORX® and TORX® Plus® have been prevalent for many years on major aircraft. CAMCAR InnovationsSM points out that Torx Plus was responsible for significant improvements in aerospace assembly operations by reducing injuries and repairs, as well as increasing drive strength and overall productivity. To expand upon these improvements, CAMCAR Innovations developed the internal TORX® Paralob drive, which amplified all the improvements TORX® Plus brought to the industry.

The first ISO aerospace standards for TORX® Paralobe™ were recently published – ISO 4579 for internal drives and ISO 4580 for internal driver bits. These standards complement the already released SAE aerospace standards AS8538 (recess) and AS3539 (bit). Of course, although these standards are created for the aerospace industry, they can guide end users to incorporate TORX Paralobe into assemblies in multiple industries.

Another example of the evolving and ever improving nature of this family is the release of the latest improvements for the TORX® TTAP® family. TORX® ttap is a jointly developed product between CAMCAR and Ttap drive AS. TORX® ttap offers significant productivity improvements on job sites utilising wood framing construction and metal roofing. This is done with the patented TTAP stability button found in the bottom of the recess.

With CAMCAR’s latest standards release, the company is continuing to improve upon the functionality and simplify the manufacturing of this product line.

Biog

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.