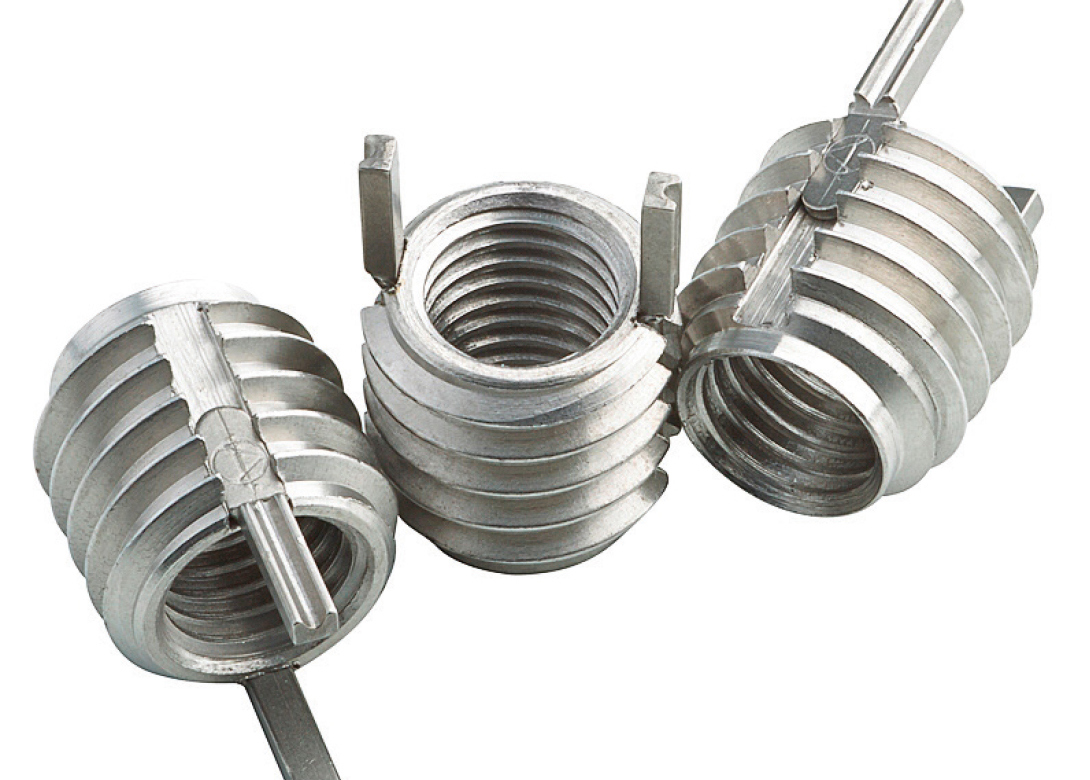

The Spiralock® brand of key inserts, offered by STANLEY Engineered Fastening, incorporate the unique design of Spiralock internal thread into the conventional key insert for use in challenging applications requiring lightweight materials and threadlocking capabilities, such as aircraft engines, avionics, radar instrumentation panels and communications.

Ongoing efforts to increase fuel efficiency, tactical mobility, and payload capacity design, in the aerospace industry have driven engineers to find ways to design components utilising lightweight materials such as composites, aluminium, and plastics. In most structural and assembly joints that use lightweight materials, the parent material needs to be reinforced through the use of a wire insert, moulded/potted insert or ultrasonic insert. However, in challenging applications where significant loads cannot be supported by the aforementioned inserts, engineers and designers may consider lightweight and heavy-duty key threaded inserts. For many years, key threaded inserts, made from stainless steel and A286, have been used with either a standard thread or prevailing torque.

Still, many applications utilising these key inserts fall short of addressing the locking limitations, and potential for vibration induced thread loosening, that is inherent in the standard 60 degree thread form. The prevailing torque thread, on the other hand, may have complications with bolt rundown and/or thread reusability.

Fortunately, advances in fastener insert technology help protect against fastener loosening or failure, while offering additional benefits of reducing assembly time, maintenance costs, and even overall weight. The Spiralock® key insert represents yet another company innovation that combines the Spiralock self-locking threads with a conventional key insert fastener. The uniquely designed Spiralock thread form offered by STANLEY Engineered Fastening enables superior locking performance when compared to standard threads and prevailing torque threads. The Spiralock design features a 30 degree wedge ramp at the root of the female thread creating a continuous spiral line contact along the entire length of the thread engagement, eliminating radial clearances and spreading the clamp force more evenly over all engaged threads. Other benefits of Spiralock include reduction of galling between screw and fastener and extended reusability for exceptional product longevity.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.