High costs during assembly, operations, and maintenance, can be avoided by optimisation in the design phase, for joining technology too. The new 3D printing service RRP – REYHER Rapid Prototyping supports companies improving component design, reducing development costs and shortening time-to-market.

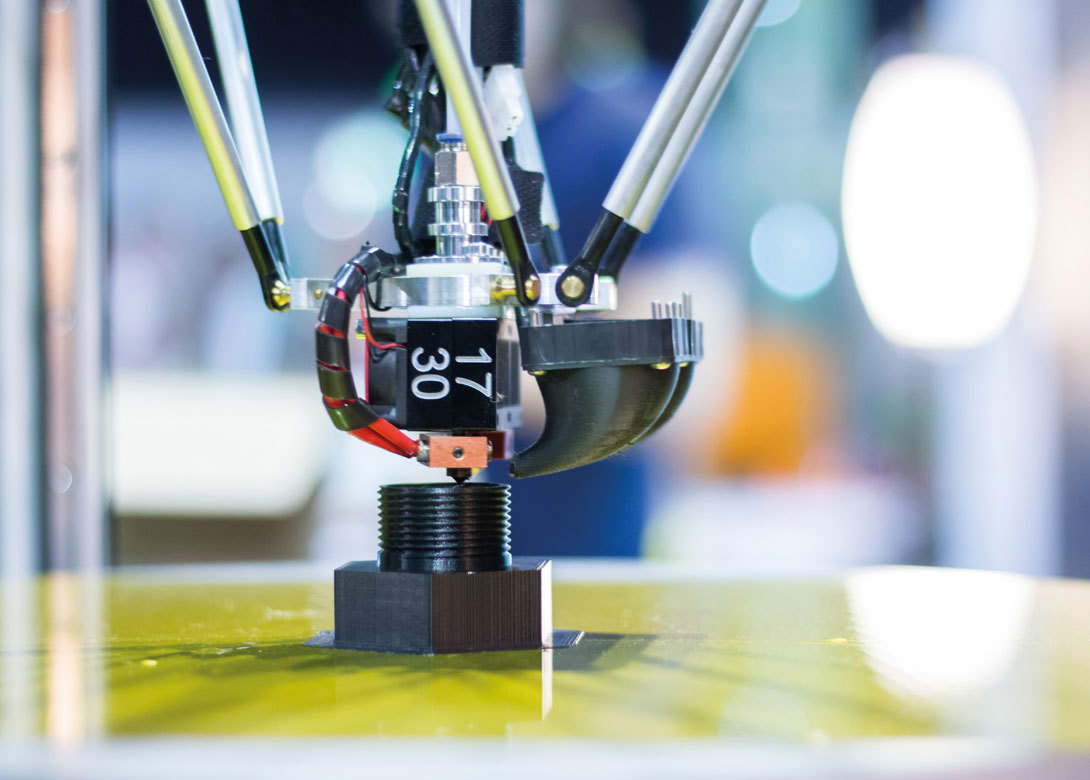

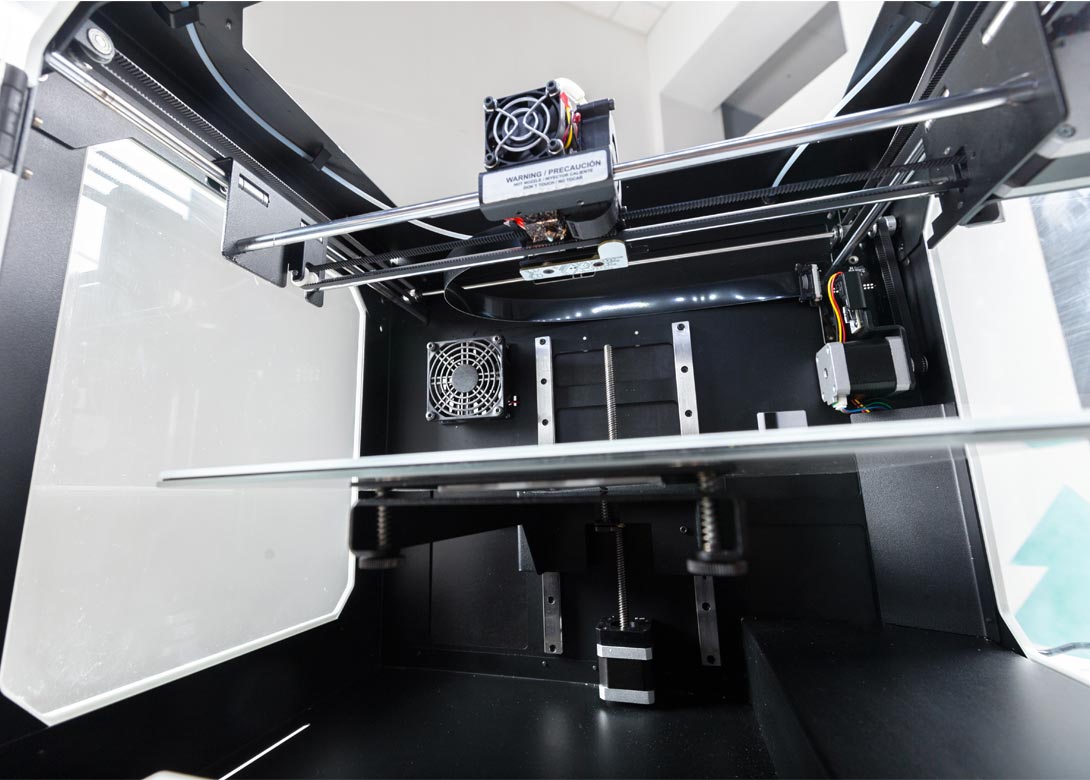

In a very short time RRP – REYHER Rapid Prototyping facilitates producing a prototype in-line with customer requirements, or a complete component as a functional model. The material can be plastic or metal, such as steel, stainless steel, aluminium or titanium. Additive manufacturing is ideal for complex geometrics, which could not be achieved with conventional production methods.

“We accompany our customers with a competent team in the development or in the optimisation of an existing solution and allow a complete treatment of the construction,” says Klaus-Dieter Schmidt, managing director at F. REYHER Nchfg GmbH & Co KG.

Three development approaches for various purposes

RRP – REYHER Rapid Prototyping comprises of three possible development paths. To develop a fastener, the REYHER team prints the screw or nut required in-line with customer requirements, first as a plastic sample part. This is useful for joining trials. “If the prototype meets the customer’s requirements then for mechanical tests or endurance testing a sample made of aluminium, steel, stainless steel or titanium is produced,” explains Gary Lee Lauf, head of quality planning at REYHER.

For development of a bolting technology, it is important to optimise the design and to reduce complexity in the construction unit. 3D printing aims to produce a functional model of the form out of plastic or metal.

The third development approach for RRP – REYHER Rapid Prototyping is complete component substitution. “In the foreground is the question of whether and how many, single units joined together in a finished component can be transformed, in order to find an economically and technically impeccable solution,” says Lauf.

Reviewing technical and commercial viability

The RRP team accompanies the customer step-by-step from the initial idea right up to the completed component. The test construction is based on CAD data of the customers’ original functional model. The current status of the component to be optimised can be printed at every stage of the development and reviewed for design, proportions and functionality.

“We check the design and the proposed material preferably at the beginning of a project using software, not only for technical aspects, but also for economic feasibility. If necessary we optimise it,” concludes Lauf.

Biog

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.