Harrison Silverdale (HSL), a supplier of threaded inserts and specialised fasteners to the plastic moulding industry, recently worked with one of its key customers to provide a threaded insert for a new moulding, to support a radiator on a luxury 4x4 vehicle.

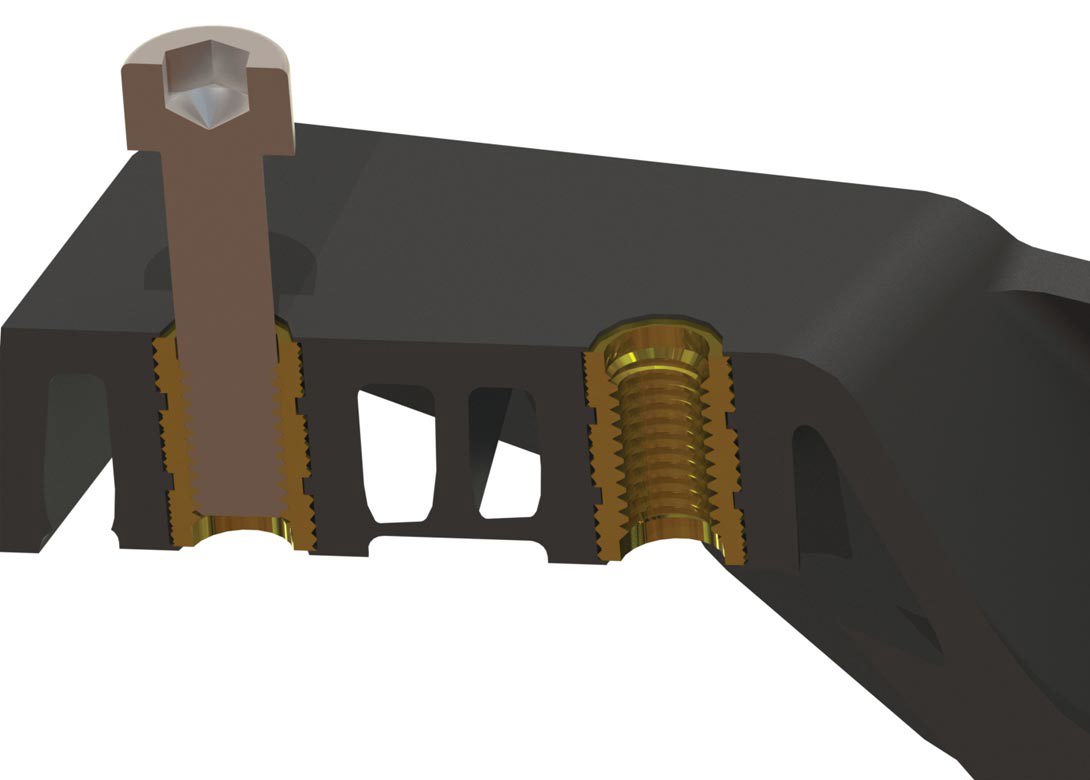

After an initial meeting to discuss the requirements HSL proposed a standard part, which would meet the design criteria. The project engineer wanted to over-mould the insert as this is more economical and provides better performance than post moulding operations.

The insert would be placed in the tool by a pick and place robot so a symmetrical design was recommended for easy orientation. Because the insert will be under heavy loads some testing was required to validate the design. It was requested by the vehicle manufacturer that HSL carry out a torque test where a number of insert locations are torqued up to double the usual tightening torque. This should then be repeated seven times on the same insert to see if any failure occurred. A pull-out test was also required to determine the force that the insert could withstand before the thread failed or the insert broke free from the moulding. The tests had to be duplicated on dry mouldings and also after being submerged in water for five days to replicate various climatic conditions.

With the help of its local UKAS approved laboratory, the tests were completed in accordance with the client’s instructions and HSL’s recommendations. The inserts passed the torque tests comfortably and withstood 4,000N pull-out with no failures, which were well above the customers’ requirements. The results were certified and submitted for approval. The mouldings will be in full production later this year with four per vehicle and run for six years.

During the development process HSL was able to receive CAD files from the vehicle manufacturer, add the proposed insert to the assembly and then share this data with the moulder and test facility. This is one of many examples of how Harrison Silverdale has offered engineering expertise at the development stage and can support customers from design through prototyping and to full production.

Biog

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.