If developers and manufacturers of fasteners wish to succeed, they must face the issue of vehicle electrification – and it’s a topic that Arnold Umformtechnik has been concerned with for some years.

Arnold Umformtechnik GmbH & Co KG began solid and comprehensive work on customers’ projects in this field back in 2016.

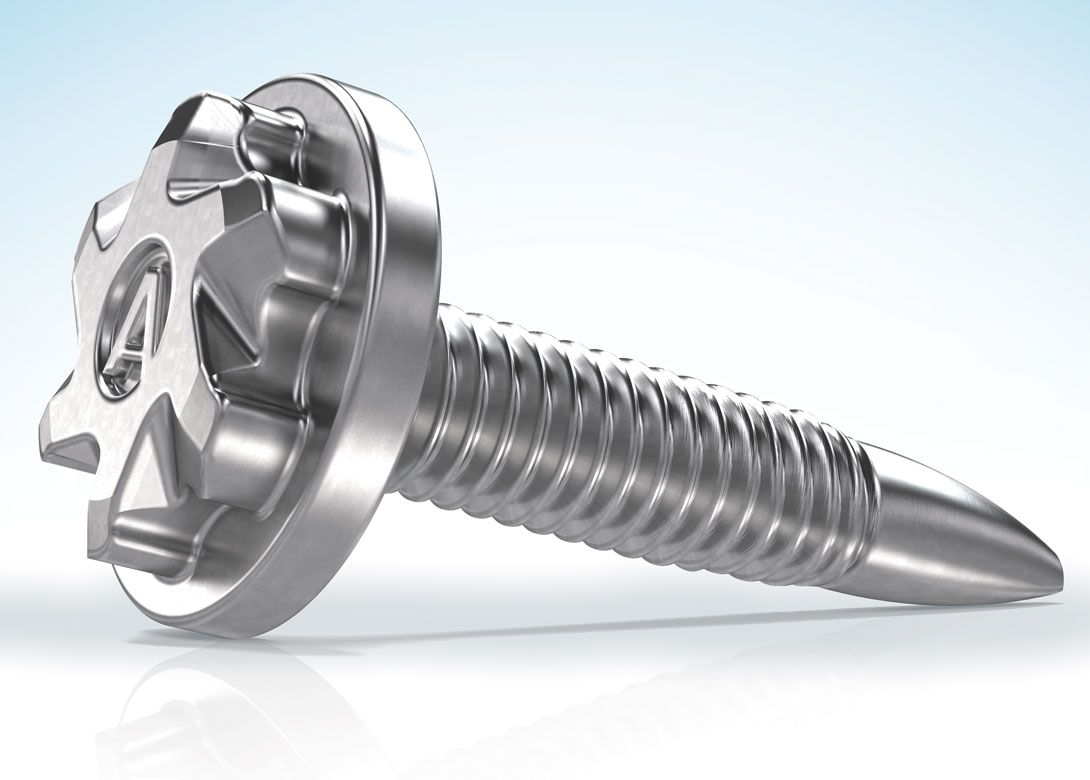

“It was the technical progress we made with our Flowform® screw that quickly convinced our customers in this sector that enabled us to enter this market,” explains the company.

Clean and reliable processing is the key feature of the thread rolling fastener, but what lies behind designing fasteners for electric vehicles? One thing is certain. Structurally sound fastening solutions are crucial.

For example, in certain applications it is important that holes are blind, so that any of the tiny particles that inevitably arise during the screw-in process will be caught. It would, of course, be a disaster if a particle were to fall from a through-hole onto a printed circuit board. Then again, there is electric current inside the battery area. That is why the material that the client uses, and the fastening solution tailored perfectly to it, play a major role.

From Arnold’s perspective, drawing parts also represent an important aspect in developing and selecting the appropriate fastening solution.

“Increasingly, turned parts are being used. Customers are often not aware that with the technology we have today it is possible to form even very complex parts such as sleeves or individual drawing parts. In appropriate numbers this creates a technical and financial advantage.”

Early collaboration facilitates the process

For the development engineers at Arnold it is important to work with the client as early as possible in the pre-development process so as to ensure they can give the expert advice on the fastening solution required. The fastening specialists are convinced this is the only way to develop and design the optimal component.

At the new metal joining laboratory in Dörzbach, Germany, fastening solutions can be tested under realistic conditions with close-to-series action. Customers will receive the screw parameters relevant to their specific application.

Besides the fastening solution and the metal joining laboratory tests, Arnold’s customers can also order the appropriate screwdriving technology, perfectly tailored and implemented – with the company’s long-standing partners – for each application.

In the case of the battery pack Arnold brings the company’s entire product range into play – Flowform for the cover, Taptite®, or even drawing parts, for various other fastenings. Arnold’s customers include OEMs and suppliers in the electric vehicle sector.

Biog

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.