Rotor Clip’s technical sales engineers are renowned for their ability to work with customers to find solutions for a variety of applications, with a recent example seeing a Rotor Clip engineer satisfy a customer’s request whilst keeping costs down.

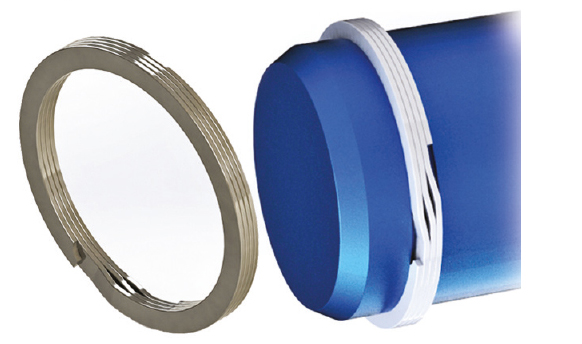

Instead, Rotor Clip engineers suggested the customer use two DSR-24s in an extra wide groove. However, using two separate rings might have caused quality issues if rings were left out during assembly. The engineers then offered a custom spiral retaining ring with 4 turns total, rather than the standard 2 turns – doubling the thrust load attainable compared to the standard spiral ring. There was also no need for custom tooling, which kept costs down.

Instead, Rotor Clip engineers suggested the customer use two DSR-24s in an extra wide groove. However, using two separate rings might have caused quality issues if rings were left out during assembly. The engineers then offered a custom spiral retaining ring with 4 turns total, rather than the standard 2 turns – doubling the thrust load attainable compared to the standard spiral ring. There was also no need for custom tooling, which kept costs down.

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.