Automated blind rivet nut solution

20 October 2016

It is one thing to solve a fastening problem and another to enable the use of up to two million fasteners per year into a demanding application, as Andy Witts, managing director at Bollhoff Fastenings Ltd, explains.

Engineering applications that require screwed fixings into thin walled components pose a problem that international fastenings specialist Böllhoff solved with the development of its range of RIVNUT® blind rivet nuts and RIVSTUD® blind rivet studs. These clever devices enable strong thread fixings where traditional threading techniques are impossible. Moreover, because the fasteners are mounted without counter pressure (fixed blind) they can also be used in hollow sections.

RIVNUT blind rivet nuts and RIVSTUD blind rivet studs are available in many variations and sizes and therefore offer numerous fastening solutions with additional functions. The nature of the components make them suitable for a broad range of adaptations and flexible usages. One such example was designed for a major international supplier of automotive ‘body in white’ products, aluminium and steel stampings, assemblies, and facilities design. The application was for a ‘body in white’ rear corner panel for a prestige British car.

The fastener selected for the task was a RIVNUT M6 closed end, knurled and with an under head seal. The RIVNUT selected has a flat head round body and is fully cold formed. It also has a knurled body for increased spin out resistance. The flat head and tapered shank makes automation and insertion easy. Internal rolled threads give increased thread strength.

The volumes of fasteners to be fitted was significant – anything from 1.4 – 2 million pieces per annum – so manual insertion was out of the question from productivity, health and safety, and quality perspectives.

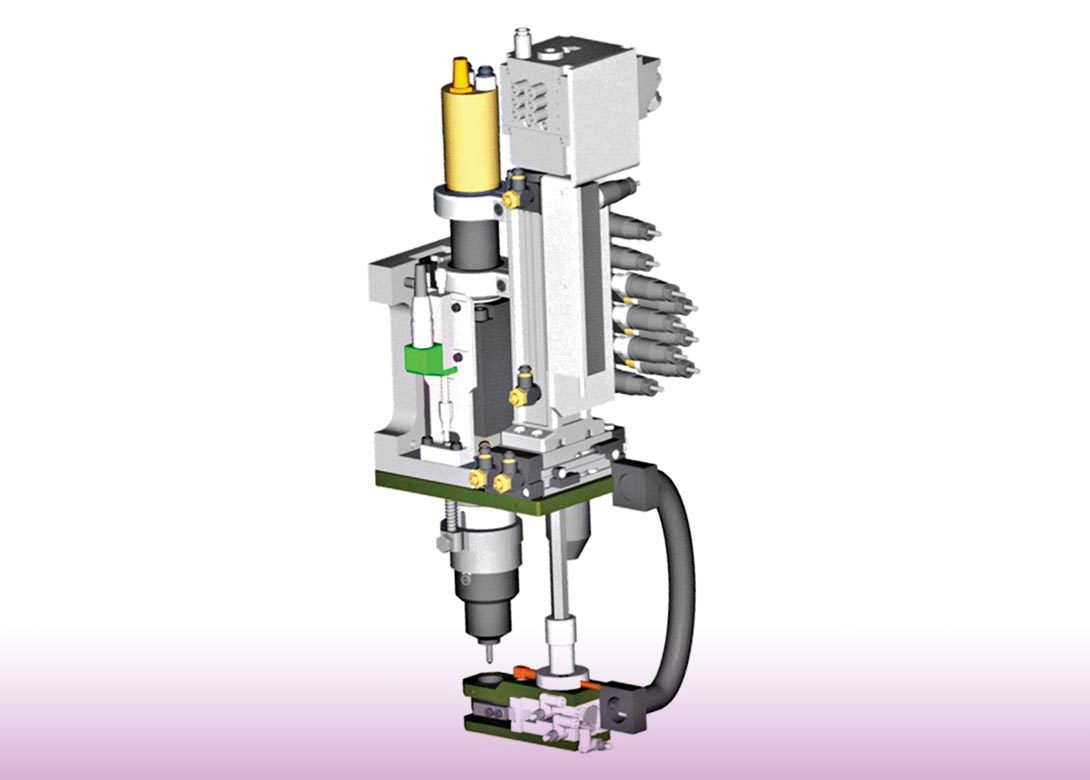

The solution was Böllhoff’s development of an automatic hydraulic setting equipment – designated HSA. This equipment proffered a number of advantages for the customer. The HSA automatic setting tool enables the fasteners to be set continuously thanks to its automatic loading system, which delivers the RIVNUT directly onto the mandrel of the HSA machine.

The fasteners are delivered onto the mandrel, inserted, and retracted to deform the fastening against the rear side of the component wall at break neck speed, every cycle, without fail.

The hydraulic setting equipment has been well tried and tested by Böllhoff in other applications of RIVNUT, while the automated feeding and setting eliminates operator error. The equipment also checks the fastener dimensions before blow feeding to the setting head, thereby ensuring no quality problems or machine jams. Thereafter, the RIVNUT insertion is monitored, the stroke and pressure is checked with the outcome that both the equipment and the fastenings are failsafe.

The HSA has been designed with system integration in mind. The use of a single external PLC enables standard protocols to be deployed to communicate between the hydraulic setting equipment and other machine tools or robots.

The electrical supply can be configured to suit the user’s needs. The setting force is 26kN for M4 to M10 fasteners. Setting stroke is 15mm and the weight loading time is just 3.5 seconds. Spin on and spin off time is a rapid 2 seconds (movement of the robot and movement of the workpiece not included).