The automotive industry cannot do without them – modern lightweight concepts. Not only do they considerably improve vehicle dynamics, they also help to reduce emissions. Here Wilhelm A. Böllhoff, joint managing director at Böllhoff Group, looks at why lightweight construction will continue to be a key technology for the automotive market in the future.

Lightweight construction is a key topic within the automotive sector for both future cars and the e-mobility market. In 1988/89 Audi started the move towards the lightweight trend with the use of the space frame for the Audi A8. The reason was that using the space frame resulted in every car becoming heavier, so companies needed to reduce weight elsewhere. In the 2000s, there was the political push to reduce carbon dioxide emissions, which created further demand for cars to become lighter.

The drive to efficient lightweight construction led to multi-material concepts for the design of cars. Nowadays there are the reliable multi-material designs with aluminium (die-cast, extruded profile, sheet metal), multiple layer joints, applications with adhesive as intermediate layer and deep-drawing steels with a tensile strength of up to 500MPa.

All these different multi-material concepts led to innovative fastening technology being needed – a prime example of this is the established RIVSET self-pierce riveting technology, which allows users to join different materials in a single production without pre-punching.

Now, high strength steels with a tensile strength of up to 1,600MPa have been added, which are suitable for series production. In the context of lightweight construction and the use of related materials, the self-piercing riveting technology with semi-tubular rivets had to be further developed beyond the known technology limits.

High strength results

As a fastening technology expert, Böllhoff develops fasteners according to the material trends. A great number of fastener varieties result from the many possibilities of use. For instance, RIVSET self-pierce rivets can vary in geometry, hardness, surface, head shape, shank length and diameter. The application defines the rivet type.

Resulting from continuous further development, Böllhoff introduced the RIVSET HDX for solutions to join materials with tensile strengths of up to 1,600MPa and a sheet thickness of 1.8mm in the top layer in series. The fastener geometry of the RIVSET has been optimised and the rivet hardness adapted. However, today’s body designs are not only characterised by an innovative use of materials.

E-mobility the future?

With e-mobility we see more opportunities than risks. However, the car market today is around 85 – 90 million cars, and forecasts are predicting the market is set to grow to 120 million by 2020. The majority of this growth will be through traditional cars (diesel and gasoline), with e-mobility representing only a small percentage. Maybe in 10 years the growth of traditional engines will start to decline, and e-mobility might increase, but at the moment I don’t think the infrastructure within cities across Europe is really prepared fully for e-mobility.

We are however currently working with a leading e-mobility OEM in the USA and our ability to supply the installation machinery and products is a big benefit for us because it means that the interface and system is from one company. In the case of development, this means that customers are working with one partner not two.

We also see China as an interesting market for the future as it is investing heavily in the manufacture of e-drive cars. There are brands in China under development, which Böllhoff is working with, that will not be known in the market. But there are some very exciting projects that in five years will be very interesting. I think it is the Chinese attempting to become a key player within the e-mobility sector. There is no point competing against the established western manufacturers for ‘traditional’ cars, but the e-mobility market is a different matter.

Providing joining solutions

For us innovation means real innovations and new technologies, as well as the continuous aim to multiple and improve the design of old products to become better. A good example is the HELICOIL, which is an old technology with a patent from the 1930s. However, in addition to still having a high usage within the market, we are inventing a lot of improvements within the HELICOIL – so the installation can be faster; security can be better; and users you can use different installation tools.

Automotive customers are also more willing to work on new solutions with us. There are some OEMs that have huge development departments for joining technology, but our customers can rely on us and our technical knowledge. It is about having a constructive cooperation to get the best solution. By working with automotive customers we can help improve lifecycle costs and cost weight reduction. However, it does depend on the type of car.

At Böllhoff we are heavily involved in the luxury and middle-sized cars, where the costs don’t have such a big role and the move to lightweight concepts is more prominent and they are open to different technologies. For the smaller cars they are still using more welding, and there is not as much pressure to reduce the weight.

When there is a pressure to reduce the weight there has to be standardisation within the products, because it is not cost-effective to have lots of different technologies. This is where innovation can play a key part because to become better in production, standardisation of the products and processes plays a vital role. One example was the Audi Q7, which weighed more than 2 tonnes. For the new model Audi wanted to reduce the weight below 2 tonnes. We were heavily involved in this project because of the joining technology. We helped reduce the material weight, by introducing new joining solutions.

One of the challenges of working with an automotive OEM is that you have to be able to innovate for the future. The cycle time of a car is maybe 6 – 8 years, so when you see a new car today in the street, we are already working on the next model that will be introduced in 2024.

Standardisation is also good for the volumes of the market. That is why we have invested heavily in the RIVSET elements over the last six years, to be able to produce double the amount – 3 billion. However, we are already looking to double it again.

Maximum life and minimum maintenance

Böllhoff has also broken new ground with the innovative assembly system RIVSET Automation EH. For this assembly system, the focus is on the functionality, flexibility and design. Plus, a long life, maximum availability and minimum maintenance – this is the foundation for effective production.

The intelligent machine variants – modular, comprehensive range – allows high flexibility for prototyping to large-scale production. The fast and high performance control provides and open software interfaces for robot communication, as well as for provision of data via OPC UA.

The main requirements for such systems are a 100% electrical installation on robots (no hose coupling), the compensation of punches (for high strength steel applications with tensile strengths up to 1,600MPa) and short process times – for some application < 1.5s. These systems are hard to outperform, since a TPM-concept is also provided.

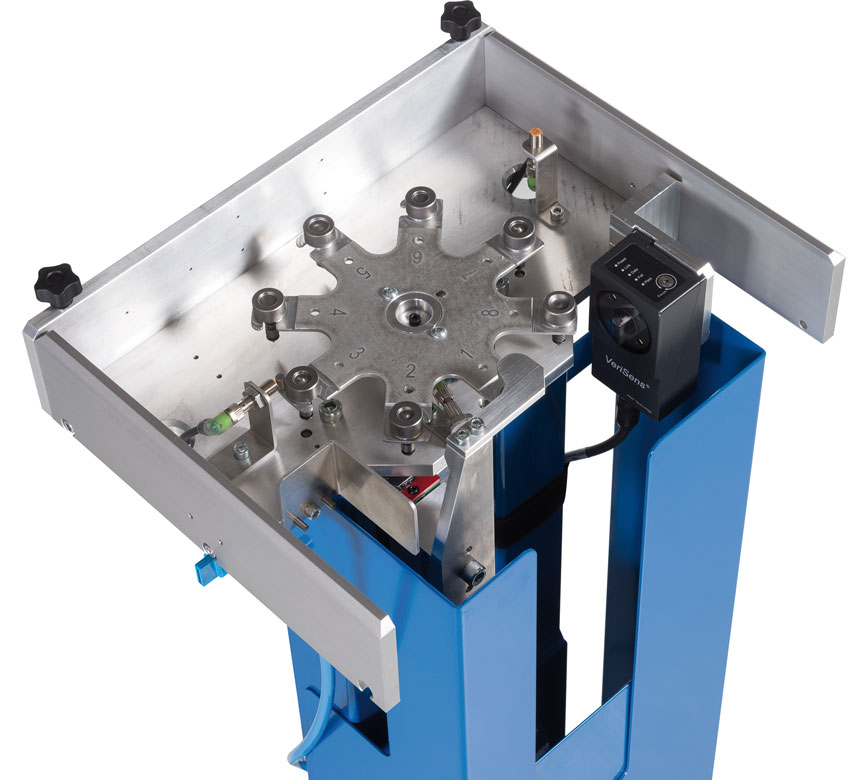

Further technical key highlights are the new die changer, the new magazine feed, as well as the new RIVSET feeder with simple feeding technology. The new die changer is suited for up to 8 dies and die changing takes less than 6 seconds. The optional automatic 100% die recognition improves production reliability.

Nothing compares to the new magazine feed. Rivet sequences of the same rivet diameter and up to eight different rivet lengths are processed. Partial loading and buffers are available. A die change takes less than four seconds and is executed during non-productive cycle times.

Plug & play

For modern production systems, production planning and control are also of great importance for defining and optimising manufacturing processes. In cooperation with customers, they elaborate new concepts, such as a software-based workflow to plan and handle the procurement of process devices. Transparent and project specific data and information are thus guaranteed. Another example is an intelligent delivery concept based on the modular design of Böllhoff components. Time critical machine components are separated from non time critical components. Those are two concepts that are very useful contributions to a flexible and equally efficient production and procurement planning.

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.