Rivit Srl is a leading company in the production and distribution of fastening systems and can offer a comprehensive range of products, thus satisfying the needs of the most demanding customers.

Within the range of Rivit’s proposed materials, stainless steel is an indispensable choice for any application that requires resistance to corrosion and atmospheric agents. To meet the needs of sectors such as marine, electronics and transport, Rivit has been developing various types of stainless steel fasteners, such as blind rivets, rivet nuts and screws.

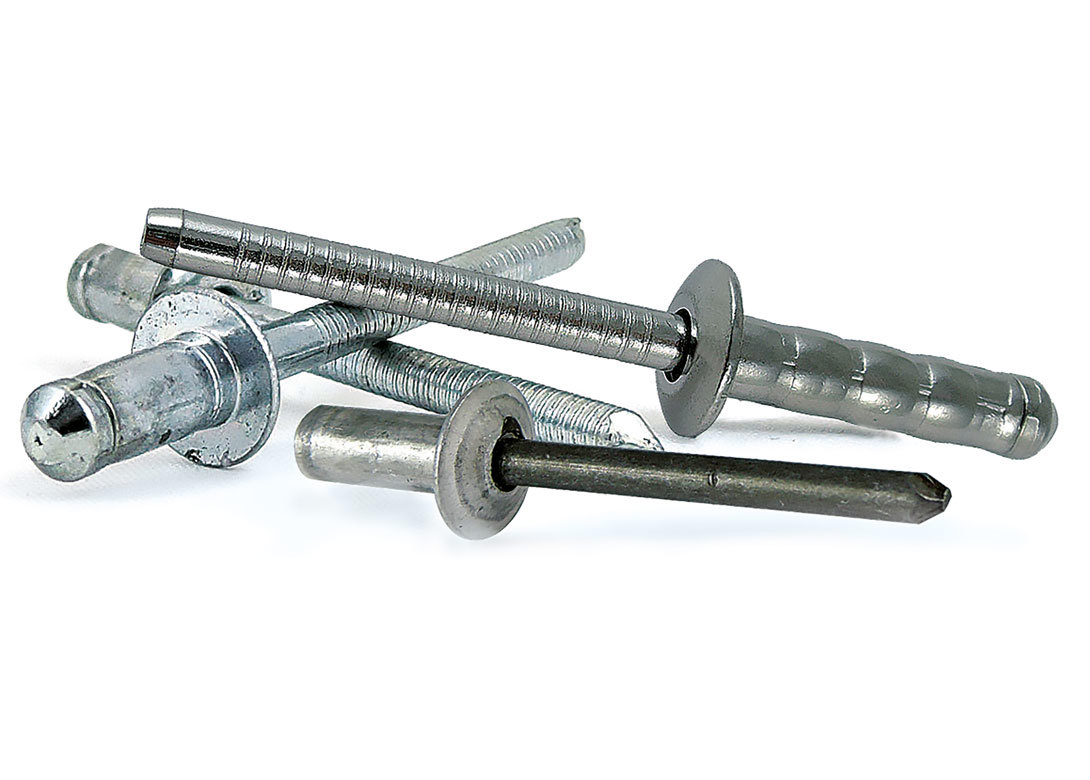

Firstly, there is the Lockriv, that’s main feature is the body deformation by compression – creating a large blind side bearing area against the rear sheet, assuring a wide tolerance with the hole diameter, as well as high shear and tensile strength – making it ideal for applications on fibreglass.

Next is the Multigripriv, with a sole rivet length that can grip various thicknesses. The particular shape of the mandrel and of the body, during the deformation by compression, creates a large blind side bearing area against the rear sheet, assuring the complete hole filling.

Other products include sealed rivets, which are characterised by a sealed end instead of the standard open hole and are suitable for containers or boxes to prevent the leaking or penetration of fluids. Within its range of rivet nuts, Rivit highlights its ITC-Z stainless steel rivet nuts, with open splined cylindrical body and dome head; and its IRC-Z stainless steel rivet nuts, with open splined cylindrical body and reduced head.

Another product available from Rivit is the Jackriv rivet nut, in AISI 316 stainless steel, M6 – M8, which are designed to provide maximum clamping action over a wide range of material thickness – creating female threads where there is no access to the blind side.

The special Jackriv geometry, when deforming, creates a large blind side bearing area, which ensures integrity of the parts to be assembled, especially on plastics and composites. During installation, the body is compressed to form a star; which makes the Jackriv highly resistant to sharing stress and vibration, but also easy to apply.

Ideal fields of application for these rivet nuts are composites and plastics, such as display panels, sandwich sections, household appliances, containers buses and caravan panelling, and internal parts of ships.

Rivit is also able to supply the installation tools for all blind rivet and rivet nut lines.

Finally, the most widespread system for removable fastening is the screw, which is why Rivit offers a wide range of stainless steel screws – available in A2 and A4 stainless steel – including cylindrical, countersunk, hexagonal head screws, metric and self-drilling screws, socket set screws, hexagonal domed cap and flange nuts, washers, pins, threaded rods, rings, eye nuts, jaws, and turnbuckles.

Find Rivit at Fastener Fair Stuttgart on Stand 3.1702

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.