Lazpiur has introduced its new IRIS range of inspection machines to meet the demands of the market, which the company reports is also the most powerful hardware on the market.

For more than a century, Lazpiur states it has been at the forefront of research, technology and innovation, developing and offering efficient, precision solutions for high-quality machines – all in accordance with the most exacting standards.

Through constant evolution, and the development and integration of diverse inspection technologies in its machines (vision, laser, photometry, eddy current, deep learning), the company can offer solutions for every control requirement demanded by the market.

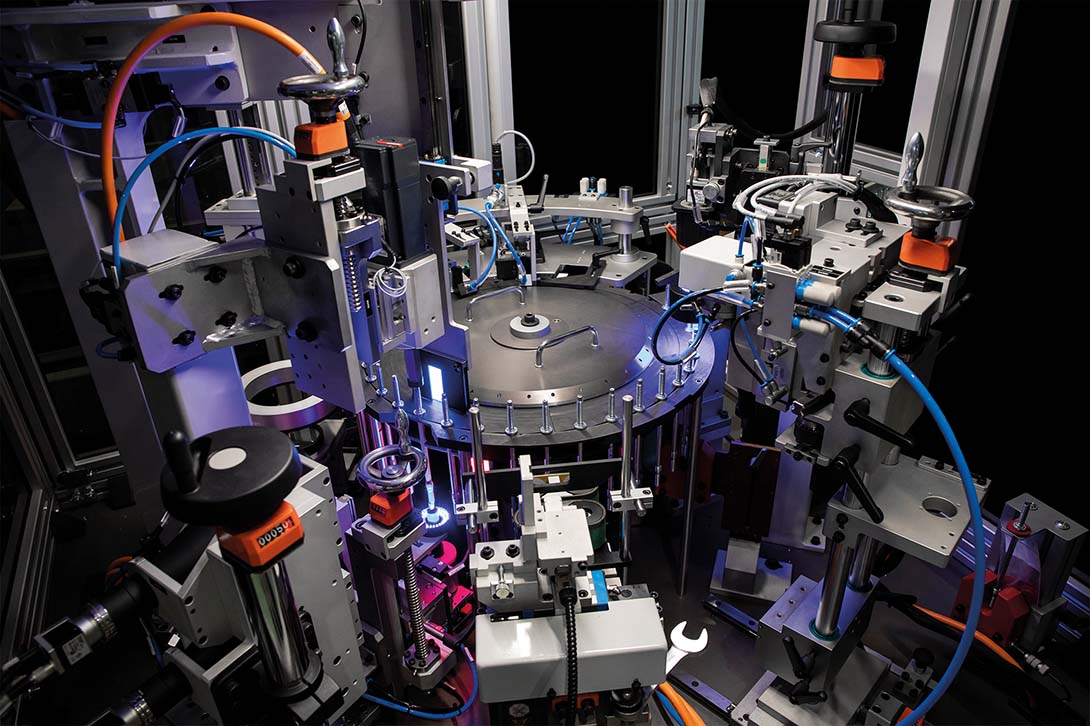

The new IRIS range of inspection machines include functional design and construction through their modularity; Lazpiur’s own proprietary UI and testing software, which is 100% verified; as well as offering connectivity, traceability and service through its Smart production and Industry 4.0 capabilities.

“Based on our own design and modular structure, we have chosen a compact, modern layout for optimal, modular inspection processes. Machine configuration can be personalised, allowing the use of different machine settings on the same platform. The overall accessibility of the machine, its ergonomics, and aesthetics, are other parameters that have been thoroughly examined,” points out Lazpiur S.A.

The new IRIS machine also uses the latest generation of PLC to handle all machine movements and incorporates an expandible, maximum-spec industrial PC with the latest processor. This gives the machine the capacity to capture and process up to 20,000 images per minute.

To go alongside IRIS, Lazpiur is also able to offer a new platform of multi-machine software called LISP, entirely developed in-house. “LISP brings together all the experience and requirements of the market as far as 100% inspection is concerned,” explains Lazpiur. “The software platform is modular and scalable, employing technologies such as back/front lit multi camera vision, photometric stereo vision for fine defect analysis in 360º, eddy current crack and heat treatment inspection, 2D and 3D laser LED sensors, colorimetry, GO/NO GO mechanical controls, printing, QR reading, machine learning, and a variety of other features and benefits.”

Lazpiur continues: “In the application of these technologies on our IRIS platform – aside from the classic solutions optimised for dimensional measurement, crack and heat treatment inspection – the inclusion of photometric stereo vision systems for defect detection in surfaces, and the application of Deep Learning in screwythread control processing, are particularly of note and will appeal to customers.”

Finally, the IRIS family of inspection and sorting machines is also suited to the newest market trends in terms of Industry 4.0 and Smart production. “Machine connectivity is total, both for the customer and for Lazpiur service. Every one of the pieces inspected is recorded by the machine, ensuring total data traceability. Furthermore, the LISP software platform also has an offline version, which can be installed on any computer, thus enabling ‘off machine’ use in programming, testing, training, etc – without having to stop the machine to do so.”

In addition to all this, Lazpiur also adds its Lazpiur Remote Service, so the customer can count on advice to help guide them in addressing their needs (programming of new pieces, addition training, error correction, etc).

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.