Voith Turbo H + L Hydraulic GmbH & Co KG, a manufacturer of highly dynamic hydraulic systems and components, has recently added a ROM RFID BOX ID solution to its REYHER Kanban supply system – enabling automatic order handling to optimise the sourcing process.

The ROM RFID BOX ID solution is a REYHER own development and can be easily integrated into a Kanban supply system already in operation. Voith says it had already been using REYHER’s Kanban supply system for some time as reliable supply of high-quality fasteners is absolutely essential for the flexible manufacture of hydraulic systems.

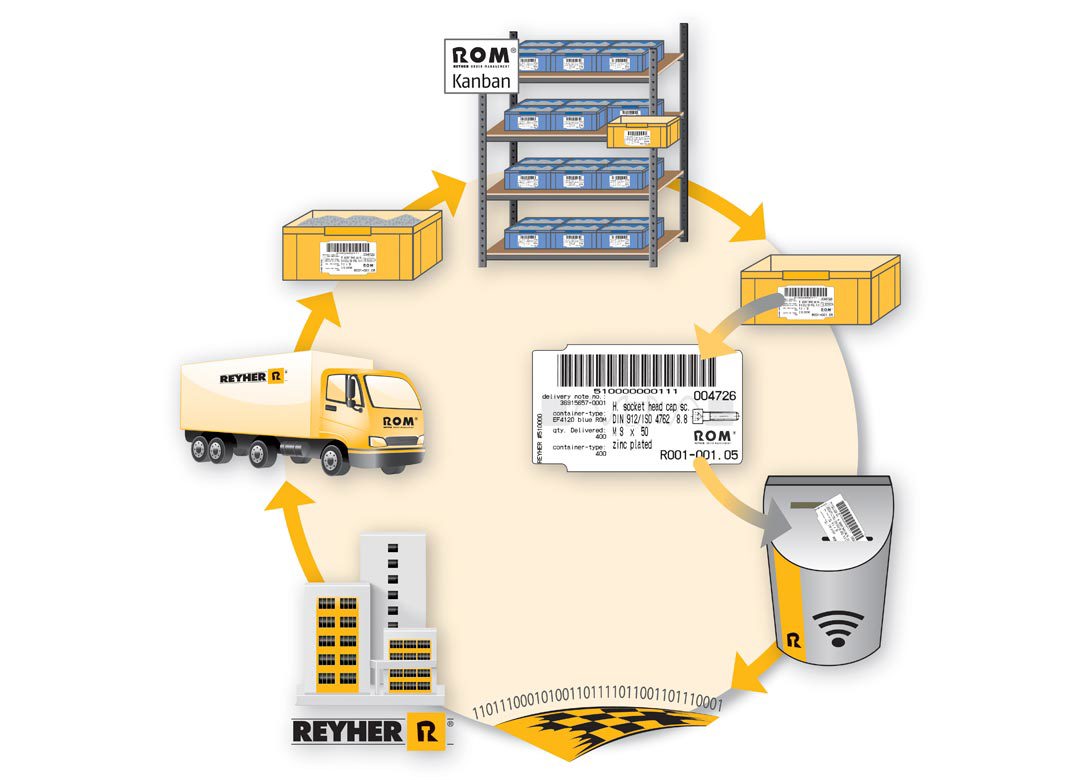

When introducing REYHER’s C-part management system, the focus was to optimise process costs and maximise the reliability of material supply. At Voith’s German Rutesheim site, assessing requirements was previously carried out by removing the labels on the front of the empty Kanban bins and placing them in a collection box. This was emptied twice a week and the barcodes were scanned by hand. The data was then sent off and used to complete an order.

With the newly installed ROM RFID BOX ID, REYHER says the ordering process is more efficient, easy, fast and precise. The process also requires the labels from the empty Kanban bins to be put into the postbox, however, the big difference is that the labels and the postbox are fitted with RFID technology. Manual label scanning is completely obsolete using this solution and no one needs to be reminded to empty the postbox at the scheduled times. Orders are placed automatically by radio signal as the labels are put into the RFID postbox. This REYHER solution also offers the unique alternative of being able to issue repeat orders for an article at the press of a button.

Andreas Laub, purchase department manager at Voith Turbo H + L Hydraulic, explained: “Integration of REYHER RFID, replacing the need for manual label scanning, created time savings and simultaneously increased process reliability.”

He added: “Since the introduction of RFID any logistics operative can trigger new supplies at any time, simply and quickly by putting a label into the RFID box. The colleagues responsible were very enthusiastic. Alongside reliability of supply and process optimisation that is an important argument.”

Supplies are delivered to Voith Turbo H + L Hydraulic twice a week and are sorted directly into the shelves by REYHER. Every delivery has a new label with the current data and a sketch of the item.

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.