A market leader in CLT system engineering products, SWG Schraubenwerk Gaisbach GmbH – a daughter company of Würth Group – is best known for the manufacture of the ASSY® branded screw. Claire Edwards, deputy editor, visited Waldenburg, Germany, to find out more about SWG’s Production division and the capabilities of its high-quality screw manufacturing facility.

In 1958 Prof Dr h.c. mult. Reinhold Würth established a production facility manufacturing brass screws at the Würth facility in Künzelsau, Germany. Due to the rapid development of the production unit, it was relocated to Gaisbach in 1962. Five years later, SWG Schraubenwerk Gaisbach GmbH began trading independently and its core business – chipboard screws – gradually replaced the production of brass screws, and the company continued to grow at the same rate as Würth Group.

Today, thanks to decades of experience and cooperation with clients worldwide, SWG Production specialises in the development and production of top quality wood construction screws, including fully threaded screws for heavy timber applications (CLT). Its wide range also includes metal drilling screws and screws for joining plastics – for a multitude of different applications such as wood construction, frame carpentry, cabinet making, prefabricated house building, and façade building, as well as individualising of customised applications.

The main focus of the production unit is the ASSY® brand of screw – given its name because of the asymmetric, symmetric thread. SWG offers the full range of ASSY screws including the universal ASSY 3.0 screw; the ASSY 3.0 SK – designed for use specifically in timber construction and carpentry crafts; the ASSY P – suitable for the attachment of panel materials; and the ASSY plus VG – a fully threaded universal screw, which can be used in the wood glue sector, carpentry, and wood and modular construction industries.

SWG is constantly expanding and developing its product range, with innovation and development at the heart of the business. In January 2014 an engineering bureau was established in order to support the customers in the field of high performance timber engineering.

“An explanation is often required in order to grasp the actual performance potential of the screw in wood construction,” explains Tobias Schneider, head of sales at SWG Schraubenwerk Gaisbach GmbH, production division. “Therefore the engineering team supports the company and its customers in the planning and implementation of customer construction projects.”

Thanks to its modular technology building block system – which enables the combination of various head, thread and point geometries – SWG can cover a wide and comprehensive CE product range with a Würth ETA (ETA – 11/190). This applies to the smallest chipboard screws with a 3mm diameter up to screws for timber engineering with a diameter of 14mm and a length of up to 1,500mm.

SWG ensures the high-quality and performance of its screws by obtaining approvals, not only in Europe but also for key target markets such as North America. In 2013, the CCMC 13677-R was obtained from the Canadian Construction Materials Centre (CCMC). In 2014 SWG also received ESR-3178 and ESR-3179 approval from the US – enabling SWG ASSY screws to be used for wood construction across the entire North American region. “SWG is the first production facility to have obtained all three of these technical approvals,” states Frank Föllinger, project manager sales at SWG Schraubenwerk Gaisbach GmbH, production division. “Thanks to more than 40 years’ experience, a future orientated management, and our modern equipment, we are able to offer bespoke solutions with uncompromising quality.”

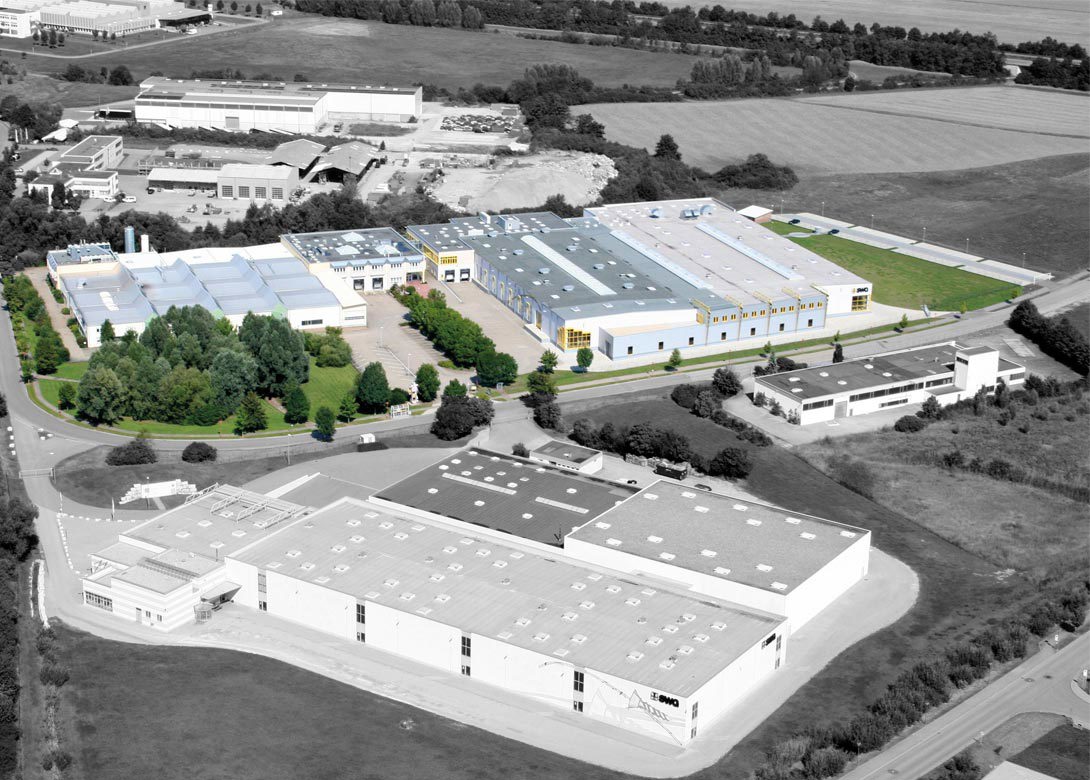

SWG’s impressive 15,000m² production facility guarantees the quality of the products thanks to its vast number of machines including cold forming and thread rolling machines. “We produce such high volumes that efficiency is vital across all departments within SWG. Our production floor is run in a clear, concise manner where communication is a key factor,” states Frank Föllinger.

Every machine operator is responsible for several machines and is kept updated with sales figures and production targets – clearly displayed at the front of the production floor. In addition, SWG’s extensive thread rolling department enables it to offer a wide range of single, double, course, part and full threads.

After pressing, the screws are moved to SWG’s pinch pointing department, which currently runs at a very high capacity with millions of screws a day. Batches are then moved to SWG’s on-site heat treatment department comprising of five two-process heat treatment lines to facilitate hardening, annealing and tempering.

SWG also has a quality control department that encompasses tensile testing machines, hardness testing devices, torque testing equipment, and profile projectors.

SWG Production employs 191 staff members across all departments including manufacturing, development, quality assurance, sales and marketing, and IT. “SWG would not be what it is today without such incredibly hardworking staff,” explains Tobias Schneider. “SWG Production stands for quality and high-end engineering. We create jobs and give people a future.”

The high qualification of its employees is achieved through constant training and further education within the company. SWG offers five types of apprenticeships within the business and currently has 15 trainees within the company. “It’s important for us to nurture our employees and encourage them to pursue their own ideas,” mentions Tobias.

The sheer scale of production at SWG is extremely impressive. Its commitment to quality and efficiency has enabled it to establish itself as a reliable partner for timber engineering. “Our goal is for SWG to be a technology leader together with our sales distribution network,” states Tobias. “Deep-rooted in Germany, we are a reliable partner in the field of timber engineering and look forward to creating new partnerships worldwide, and products, in the future.

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.