R+FK Schulte KG is a washer manufacturer that is taking on the challenge of becoming a ‘one stop shop’ for both standard and special washers – looking to utilise its ability to produce washers quickly and cost-effectively with ‘Made in Germany’ quality.

Originally known as Rudolf & Friedrich Karl Schulte oHG Press- und Stanzwerk – after brothers Friedrich Karl Schulte and Rudolf Schulte merged their companies into a general partnership – the washer manufacturer, now better known as R+FK Schulte, has been located on the same site in Plettenberg, Germany, for over 80 years.

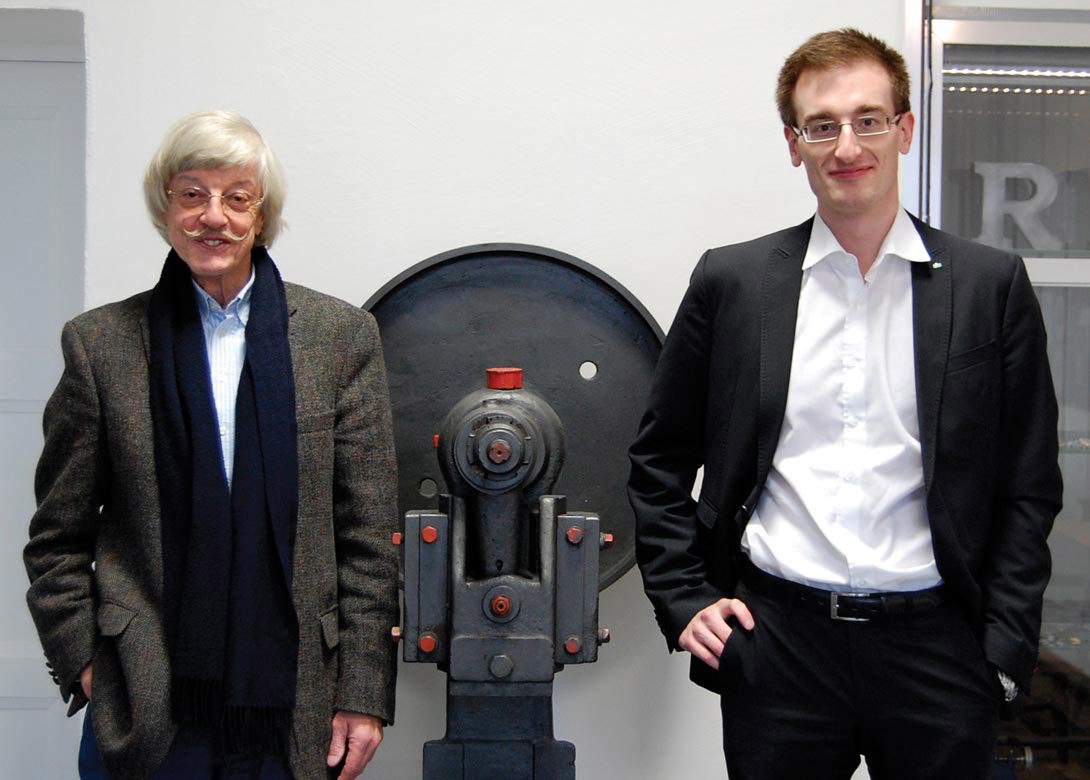

R+FK Schulte is still run by the Schulte family with F. Wolfgang Schulte, son of Friedrich Karl Schulte, the owner of the business and Wolfgang’s son Carl Philip Schulte the deputy chief executive officer. “We are very proud to be a family business and to still be producing everything in Plettenberg, including the tooling for the machines,” states Carl Philip.

Producing in Germany is a key part of the business and enables R+FK Schulte to underline the quality of its products. “Quality is a very important factor for us,” says Peter Schlütter, sales manager at R+FK Schulte KG. “We have one of the biggest and widest ranges of standard washers according to DIN/ISO standards and can also supply a great variety of special parts. It is vital that all our products meet the high standards we demand.”

“Being able to fulfil the quality demands for both standard and special parts puts us in a very strong position with customers,” adds Carl Philip. “Our customers can be confident in ordering all the washer products they need in any size – from one source – knowing that they will get a consistent high-quality product.”

R+FK Schulte’s ability to produce such a wide range of standard and special washers is down to three important elements – the machines, the tools and the employees. “If you have the know-how of these three areas then you have the ability to always produce a good quality product,” points out Peter.

The company’s machining capabilities enable R+FK Schulte to produce washers with a thickness from 0.05mm up to 12mm – once again underlining the company’s competence. “Products with tight tolerances require machines and tooling with tight tolerances,” explains Carl Philip. “Our production is broken down according to product dimensions. It does not matter if it is a standard or special part, it is the dimension of the washer that determines which stamping machine is used. This means that we do not differentiate between the quality of our standard or special parts – they all have to be the highest quality.”

R+FK Schulte produces to the high standards of the automotive industry and has achieved ISO/TS 16949 accreditation, as well as ISO 9001. “We achieved these accreditations, but they can only get you through the door to speak to customers,” says Peter. “It is only the ability to consistently and reliably produce to the highest standards that will enable you to win orders and build long-lasting relationships. At R+FK Schulte we can supply this quality.”

A vital part of R+FK Schulte’s quality is its impressive tooling department and the vast depth of experience and knowledge of its tooling employees. “The tool shop is the beating heart of the company,” states Carl Philip. “Every tool that is used on the machines has been built in our tool shop. Thanks to the experience of our employees, we are able to create a wide range of new tooling – especially for special parts – which uses all of the knowledge and skill that has been passed down over the last 80 years.”

“We are immensely proud of our tool shop and its capabilities,” continues Peter. “We are regularly investing in new machinery to ensure that we are able to keep up with the latest technology and ensure that we are always able to offer the necessary tooling for customers’ solutions.”

Since its foundation, R+FK Schulte has always had the philosophy to reinvest profits into the business – focusing on growing organically whilst increasing productivity and efficiency. A prime example is the company’s recent decision to invest in a new 800 tonne stamping machine, but it wasn’t a simple case of just buying the machine.

“We wanted to increase our capacity and improve our production process, which is why we wanted the new 800 tonne machine, but our production area was already full of stamping machines,” explains Carl Philip with a smile. “Stamping machines aren’t the smallest machines, so we realised that if we were going to introduce the new machine we would also need to build a new production hall.”

So that is exactly what the company decided to do. Started at the beginning of 2015, the new 2,000m² extension is now complete with the 800 tonne stamping machine already set up and working on series production – giving R+FK Schulte the ability to be more productive and improve cost-efficiency for larger washers.

“When it comes to stamping, it is all about the parts you can produce,” explains Carl Philip. “The new machine is designed in a way that it works with special or standard parts that have a thickness of up to 12mm – in series production.”

“The new machine has definitely increased our capabilities,” adds Peter. “However, you can only create high-quality products if you have the knowledge and experience that helps you to realise features that other companies cannot.”

The ability to realise features and work with customers on the development of special parts is something that the company wants to develop further. “The special parts business is about gaining knowledge and improving and improving again,” says Carl Philip. “We work closely with our customers on designing new parts to drawing, but also by looking at their application and whether we can substitute turned or hot forged parts into stamped parts. This is becuase stamped parts can offer significant cost savings, whilst still providing the customer with a quality product.”

Carl Philip continues: “Another key benefit we can offer is that we are also set up as a mass producer – all our processes, structures and organisation are streamlined to this – which has a great effect on our cost-efficiency. We can translate this into our special products, which means that we are not only attractive to customers for the technicality of our special parts but also the cost-effectiveness of them.”

60% of R+FK Schulte’s customer base is distributors and wholesalers – mainly in Germany but also across Europe. Screw manufacturers – which require washers for screw and washer assemblies and HV sets – make up 30% of the customer base, with end users accounting for the final 10%. “We see wholesalers and distributors as partners that enable us to get to key markets and we work very closely with them,” mentions Peter. “By having a tight relationship we feel the pressures on the market and the prices, and try to pass cost savings onto the customer. The screw manufacturers are also essential partners as they challenge us with complex solutions for assemblies where our technical competence is giving us the edge over our competitors.”

R+FK Schulte is keen to continue to build its relationships with customers and ‘go the extra step’ where possible – as it did with its recent investment in its packaging department. The company has introduced three automatic packing machines – poly bags as well as carton – within the last two years. “Whilst it is not a core part of the business, we realised that we needed to be flexible to our customers’ requirements,” explains Carl Philip. “We therefore invested in the additional packing lines, which enable us to offer more capabilities and improve the overall process.”

This commitment to being flexible to customers needs – supported by a wide range of standard products – plus the ability to work with customers on special parts, means that R+FK Schulte has a commanding portfolio to offer customers. With Carl Philip in the company, the next generation has been established and solid foundations are being laid to take the next step in the company’s development.

“It is important that we prepare for the future and continue to provide both standard and special parts in the most effective manner possible,” states Carl Philip. “We will stick with organic growth and will keep our philosophy of reinvesting back into the business. In fact we already have two additional machines on order, which will be installed and running by the end of the year.”

Carl Philip finishes: “We are 100% committed to what we are doing and look forward to continuing to deliver a quality product with a first class service.”

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.