To ensure that it continues to meet the demand for its products, Ornit Blind Rivets has opened a new logistics centre in the heart of Europe.

Located near Rotterdam, the Netherlands, the new logistics centre will enable customers to reduce stock on their shelves, as Ornit will be able to carry it for them. In addition, the centre’s close proximity to industrial areas within western Europe will help Ornit’s customers to increase sales in a competitive environment – with products now available overnight.

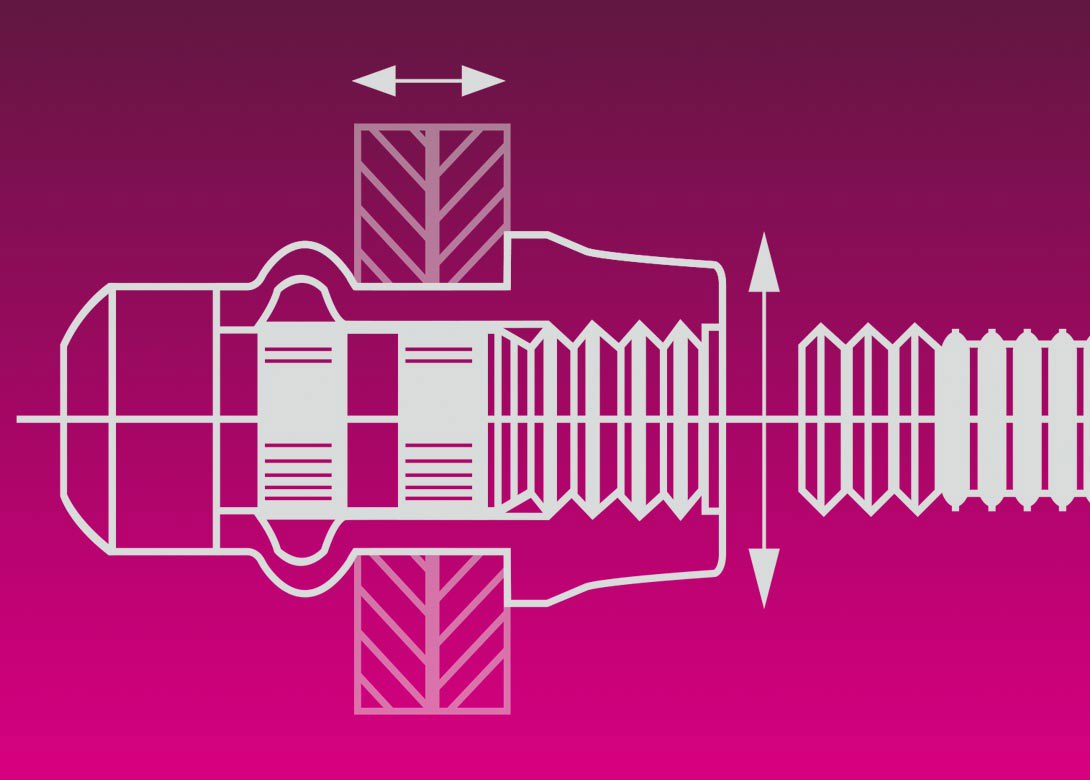

Ornit has specialised in providing fastening solutions since 1975, manufacturing quality blind rivets at its state of the art facility in Israel. The company has built a reputation as a designer of tailor-made solutions – working closely with its partners to create unique solutions, as well as using the experience and knowledge within the business to design solutions through pure innovation.

“At Ornit, creativity is a way of life,” explains Assaf Vigdor, vice-president sales and marketing at Ornit. “In addition to research and development, our innovation ideas come from personnel throughout the company. That starts from personnel at the production lines who strive to improve productivity, via engineering and quality control personnel who assure top quality products, to our application specialists who work closely with our customers to deliver unique designs.”

Due to this commitment to innovation, and through Ornit’s engineering expertise and manufacturing capabilities, the company says it has positioned itself among the leaders in the fastening industry – providing globally recognised products for the heavy-duty vehicle, automotive, renewable energy, rail, and construction sectors.

Another crucial aspect for Ornit is quality, with the company holding the highest international standards – ISO TS 16949:9001 and ISO 9001:2008. “The challenges we have overcome over the years have taught us not to compromise on quality,” explains Assaf Vigdor. “Today quality is part of the company DNA and we are always looking to further improve the quality of the products, and also the service that we provide our customers.”

This commitment to innovation and quality has led to Ornit producing a wide range of rivet product lines, as well as supplying Gage Bilt® riveting tools, including:

“Our products are available from our valued business partners, local distributors and online,” explains Assaf. “Thanks to our new logistics centre in the Netherlands we have further improved the service to our customers and can deliver products to over 34 countries around the world. The next time you have a fastening challenge, you need to contact Ornit for the answer.”

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.