A family owned company, Mustad SpA has over 100 years’ experience of producing quality and technically advanced screws – producing 3 billion screws annually.

Mustad comprises of two manufacturing plants based in the north-west of Italy, close to Turin, and is able to produce a wide range of products – with specific and different characteristics – in order to maximise performance in a variety of materials. “At Mustad we produce a lot of products – chipboard screws, screws for PVC, self-tapping screws, self-drilling screws, screws for roofing and cladding, screws for metal and wood structures, plus a lot of special items,” explains Marco Eriksson, general manager at Mustad. “We have in our catalogue more or less 1,000 standard items, but we produce in a year, around 3,000 different items – due to the number of special and bespoke parts we can manufacture.”

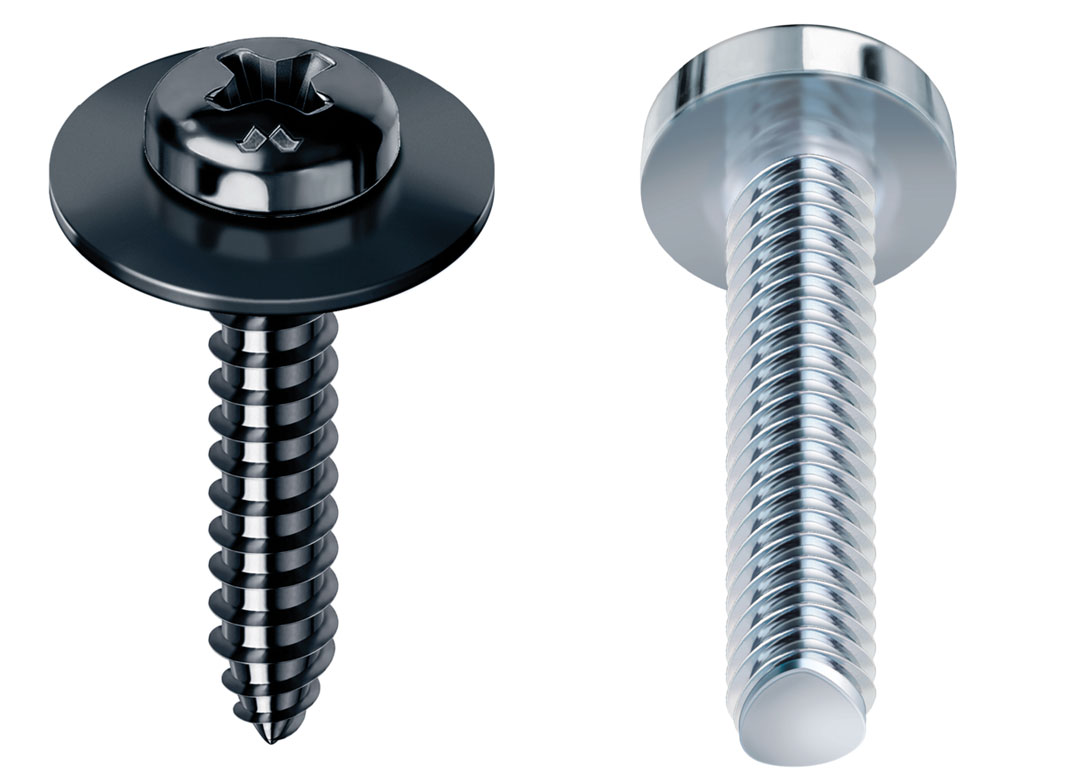

Mustad supplies products to two main sales areas – the building and industry sectors. “For the building sector we focus on screws for construction, building, windows, doors, furniture, etc,” points out Luca Molè, sales manager at Mustad. “The industry market covers a wide range of applications, including automotive, white goods and electronics.”

Whilst both industries have different needs and requirements regarding logistics and stock demands, there are also a lot of similarities from which Mustad can benefit. “We can transfer a lot of know-how from one field to another where beneficial,” mentions Luca. “There are a lot of developments and innovations within the industry market that we can also anticipate for the building sector in the future.”

Production for each target market is divided across the two sites, with all machines fully automated and connected via a network to verify productivity levels. “Our Balangero plant is our headquarters and is where we focus on specialised products for the industry sector, such as automotive,” mentions Luca. “The Pinerolo plant focuses on standard products, so the majority of its volume is for the building sector; both sites are a similar size.”

Whilst Industry 4.0 has become a hot topic within the industry, Mustad has been automating its machinery for 15 years. “We have automated step-by-step by reinvesting part of our turnover,” mentions Luca. “Every year we invest an important part of our turnover, including during the years of the big crisis, 2008 – 2009, because we benefited from the suppliers of machines offering special prices and we had the strength to buy at this point. Also, because we had less work to do we could suspend production for some parts to replace the machines, which enabled us to streamline the production process.”

Now Mustad is seeing the benefit of this investment. “2017 was a record turnover year for us,” points out Luca. “This shows the decision to invest in the machinery was the correct one and we are stronger than before. This is the advantage of being a family owned business, because the owners understand they have to continuously invest in order to grow and ensure the quality of the products.”

Providing a consistent level of quality is very important to Mustad, which is why the company works to only the highest quality level across both its sites. “It doesn’t matter if we are producing for DIY or for automotive, for us it’s the same,” states Luca emphatically. “The personnel are the same, the machines are the same, the raw material is the same, and the treatments are the same. This is crucial, because it means when customers see Mustad screws, they know they are using only one level of quality – the highest level.”

A big part of that quality is the raw material Mustad uses for all of its products, which it buys only from European suppliers. “We don’t import raw materials from Asia because we want to ensure good quality material and a reliability in supply,” explains Luca. “This has been our strategy for almost 40 years, because if we have a good quality in the base of our product, we can assure quality for the final product. It means we pay a little more for the raw material than if we imported from Asia, but the quality of the product is better.”

In addition to ensuring a reliable supply of quality products, Mustad also has the ability to draw the wire itself, which means it can benefit from buying a large stock of wire rod, in several diameters, and then carry out the drawing operation. “This is a big advantage in terms of flexibility, especially currently when companies are struggling from a lack of raw material availability within the market. Due to our drawing capability we can buy large stocks at the right time and assure wire rod for our machines without any risks.”

Mustad’s drawing capability is a prime example of the company’s vision to be 100% responsible for the entire production process. “We cannot produce the raw material ourselves, but by having drawing capability it gives us more control and opportunities,” mentions Luca. “Having control of the production process is crucial, because it means you can manage all the key factors involved in reliably producing quality products to meet customers’ demands.”

Mustad’s drive to control the entire production process includes producing part of its own tooling and dies for its machinery and having its own operating furnaces for heat treatment. “These furnaces enable us to heat treat a large portion of our products and take responsibility for a vital part of the production process,” adds Luca. “This is a big advantage within the market, as we can manage the flow of products through the heat treatment lines, whilst still guaranteeing a consistent quality and process.”

Luca is also keen to point out the importance of the maintenance team within the company. “It is through your maintenance department that you ensure all machines are really workable. We have a programme of planned maintenance, so we take machines from the lines and move them to our maintenance department. The machines are then opened up and all the parts are changed. So, when we put the machines back in the line, we can be sure that for the next two or three years, we can work without any problems.”

The only part of the production process Mustad does not have in-house is the surface coating process, instead working with a sub-contractor. However, the company has developed its own long-lasting corrosion resistant coating – Chromiting®. “Chromiting is a white zinc plated coating that we have registered as a replacement to Chromium VI,” explains Luca. “It is a universal treatment that guarantees 240 hours against red rust and can be used for indoor or outdoor applications. By introducing the Chromiting coating we are looking to simplify the buying process for our customers, as they can standardise their assortment with only one treatment.”

Mustad introduced the Chromiting coating after analysing the market and seeing how it could answer customers’ needs. “At Mustad we do not just want to copy what others do, we want to create a new trend ourselves if possible – especially in the building sector. By working with customers and understanding their requirements we can adapt our products, like we did with the finishing, to provide the perfect solution. Offering our own coating makes us stand out from the crowd, which is essential in the building sector as it is very competitive. It is different in the industry sector because here you work a lot in co-design and have closer partnerships with customers.”

Mustad has technicians that have a vast experience in working with customers to try to adapt or find the best solution for an assembly. “Sometimes it is not a problem with the screw, but a problem with the application, or with the set-up, or with the tooling,” says Luca. “However, because it is the screw that fails, the customer believes the screw is the problem. That is why our technicians work closely with customers, so we can understand where the screw is going to be used, how it is going to be installed, and what tools are going to be used for installation. By getting involved and understanding the process, we can ensure the perfect solution.”

Alongside the production capabilities, Mustad has also invested a significant amount of money in its stock over recent years – ensuring it has the products available to meet customers’ demands. “It is a big cost for us to have such an in-depth stock, but it is also a big advantage because when a customer asks for one million pieces, we have the product in stock, and can supply them immediately,” points out Luca. “Also, customers are looking to reduce the amount of stock they keep, so having large quantities available, with prompt delivery, is a big advantage in today’s market. You cannot just produce to order because that is going to take too long. You need to have the stock, and that is what we have.”

“Customers today are wanting less volumes and they work with less stock, which can make it difficult to forecast for the future. However, being an Italian manufacturer, that is really close to the customer, is a big advantage. We have a lot of customers in Germany, France and Italy, that previously worked only with Asian manufacturers, either directly or through distributors. However, they have now decided to relocate the purchase to Europe due to the long lead times from Asia. Thanks to our flexibility and stock we are able to meet this demand.”

Luca concludes: “We currently supply 70% of our products within Italy, with 30% exports. However, our strategy for the future is to grow our exports, especially across Europe. France is the most important market within Europe at the moment, but we are working in Germany, the UK, Portugal, Spain, and in eastern Europe, and looking to develop these markets further. Thanks to our production capabilities and our ability to control key parts of the process, we can guarantee a reliable and consistent supply of products to customers for every sector.”

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.