With construction fixings used in a variety of base materials and connections – including critical applications – it is vital that suppliers provide a reliable service and product. Thanks to the experience and knowledge within the company, as well as its Anchor Calculation Program, JCP Construction Products Ltd is able to expertly supply this service and more.

Founded in 2001, JCP Construction Products is part of the Hexstone group of companies and is a specialist supplier of construction fixings to distributors. Its in-depth product range varies from lightweight plastic plugs up to heavy-duty seismic anchors, which can be used in earthquake zones and power stations, plus a full range of chemical products.

“As a team we have over 40 years of experience in the fixings market and it is thanks to that knowledge we are able to offer a unbeatable range of products for customers and find the best solution for their fixing needs,” states Nick Beardon, general manager at JCP Construction Products. “All our products are supplied with a full technical specification and in many cases with a European Technical Approval/Assessment. This is imperative in an industry where quality and reliability are of paramount importance.”

Working closely with manufacturers

Although JCP is a wholesaler, it produces its own technical information for products and works closely with manufacturers to guarantee the highest quality. “When you are working on ETAs for products, it is essential that you have a close relationship with your manufacturers,” comments Nick. “That is the only way you can ensure the products meets the necessary standards.”

Nick adds: “We also develop new product ourselves, which involves going to the factories with our specification and assessing with the manufacturer if they can make it. There are then discussions and possibly modifications before the final product is produced, so it is crucial that you have an opentwo-way communication with your manufacturers.”

“According to the Construction Products Regulation (CPR) –due to the fact we sell the products under our own name we are technically classed as a manufacturer,” points out Brian Deluce, technical manager at JCP Construction Products.“We therefore make sure we are aware of all the requirements and regulations regarding manufacturing. That is one of the main reasons we joined the European Consortium of Anchor Producers (ECAP) in 2007.”

Brian continues: “ECAP gives us better contact with European regulations as they are being developed and enables us to further understand the changes that are happening. Recent examples include the changeover process to CPR, which made the use of CE marked products mandatory in safety critical applications. Through ECAP we are also part of the different groups and discuss areas regarding the new European Assessment Documents (EADs). As an SME it gives us a voice and an input into the process, which is very important.”

Guaranteeing correct calculations

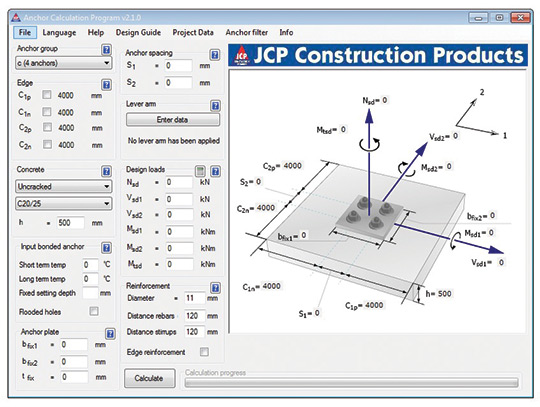

The Anchor Calculation Program (ACP), launched by JCP in 2009, has received growing interest over recent years. It provides engineers and specifiers with the ability to enter their criteria for job sites and calculate the correct JCP fixing for the application.

From its solid technical foundation it now includes a plethora of information, including fire data, seismic data, as well as considering anchor spacings, edge distances and a variety of embedment depths. Available as a free download from JCP’s website, users can easily input their information into the program and, using 3D graphics, it will consider all the available data and suggest what anchors are suitable. A large number of standard base plate and anchor configurations are available as well as a ‘custom geometry’ option. This allows for unusual base plate shapes and anchor positions, as well as moving anchors to obtain the optimum results.

“With an ACP it is vital the calculations are accurate and reliable because the anchors may be going into critical applications,” points out Brian. “That is why before any amendments or updates are made to the program, it is tested to the nth degree.”

“The ACP has proven to be a very good tool for us and we make sure it is constantly being developed and updated, as demand requires – such as regulations and processes changing,” comments Brian.

To add to the Anchor Calculation Program, JCP also now has a Resin Volume Calculator Program, which has been added to the website as a free download. It enables the user to calculate the approximate number of injection resin cartridges required to fill any number of holes of varying depths.

“The Anchor Calculation Program has proven popular with engineers and builders. We are sure that the Resin Volume Calculator Program will prove just as popular,” states Nick.

Part of Hexstone Group

Being part of the Hexstone Group means JCP not only benefits from being an SME – flexibility, responsiveness, tightknit team, offering the personal touch – but also the additional benefits of being part of a bigger organisation. “The Group has a very large supplier base, as well as customer base, so immediately there are interesting possibilities,” notes Nick.“Also, having a common sales office means customers can order everything – nuts, bolts, nails, and fixings – in one go. It is a one stop shop.”

Nick continues: “When we first started, it was a case of steering our own ship, but we soon realised being part of Hexstone gave us access to a huge resource that was a leader in the market. We therefore quickly made the most of the opportunities being part of Hexstone provided.”

JCP’s stock is stored at the Group’s main warehouse in Stone, Staffordshire, which means the company is able to offer its customers a service level of the very highest standard, as well as good stock availability. However, it is not only JCP that benefits from the relationship. “Because we are specialists in what we do, we can provide that knowledge to the other Hexstone group of companies,” mentions Brian. “In fact, we recently worked with Unifix on the ETA certification for its Thunderbolt™ product.”

Providing technical support

Whilst its stock is held in the Group’s main warehouse, JCP has a technical office in Teddington, Middlesex, where it carries out training courses and seminars. There is also a testing facility and a workshop for any tool maintenance.

“The Teddington office means we can run training courses for customers, as well as internal staff,” points out Brian. “Training can be tailored to suit the needs of the individuals and can include everything from basic anchor knowledge and range, right through to understanding ETA documents.”

The in-house testing facility gives JCP the opportunity to evaluate the products it receives from its manufacturers, as well as carry out tests on new products. “If the initial tests are positive then we send the new product to an outside test house to get it evaluated,” explains Brian. “That way we have the raw data that is independent of ourselves.”

A key service that has received more interest from customers, especially within the last two years, is JCP’s ability to carry out on-site testing to confirm the suitability of the loadings on our anchors. “We can go onto a job site and conduct a product test if we are looking to get products approved for a job,” mentions Nick. “All our sales people are certified under the Construction Skills Certification Scheme and we can produce reports for users and distributors on how the product performed. From our point of view, if we are on-site and help give that information it helps build the brand of JCP.”

Opportunities for the future

JCP is clear quality will continue to be a significant factorin the market. “You need to have ETA products in your portfolio if you are going to compete for business,” states Nick. “However, we are still finding some customers aren’t aware of what an ETA certificate actually is, even though they are asking for them.”

“One of the biggest challenges we have as an industry is educating customers on the capabilities of the anchors and the different technical aspects,” adds Brian. “We need to work with customers and explain what CE Marking and ETAs really mean, and why they are significant. It is about getting the knowledge into the market so customers know what products are available and the different options.”

“That is why the Anchor Calculation Program is so important,” says Nick. “It means customers can enter their information and get the correct product for the application.”

JCP’s ability to combine comprehensive technical information with a vast experience has seen it establish itself as an authority within the fixings sector. So what is the next step?

“Our aim for the next 5 years is to start to work with the larger engineers and specifiers and get our products specified for projects,” states Nick. “At the moment we get our products approved to say they are as good as the current products specified, but we want to be the ‘first name’ on the drawing.”

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.