By the global applications team at Helmut Fischer headquarters

Nails and other fasteners are coated to protect them against rust; the thickness of the zinc layer corresponds directly to how long they can resist corrosion. Extended warranties and constantly changing regulations make it more important than ever for the fastener industry to assess whether the quality of the plating meets relevant standards.

A wide range of fastener products (e.g nails, screws, bolts, etc) that are zinc plated, require testing to specification. Typically, this would be on hemispherical surfaces, threaded stems or cut ends. For non-destructive testing, one can employ either high precision X-ray fluorescence (XRF) or the more cost-effective phase-sensitive eddy current method. This method fulfils the requirements of the EN (DIN) 14592 classification. It is better suited than other electro-magnetic methods because of its ability to measure electrically conductive coatings – even on rough surfaces – on a variety of substrates. It also offers great advantages in measuring small objects since the geometry of the part being measured exerts very little influence on the measurement itself.

Optimal measurement results require a special probe that enables small measurement areas on curved, rough surfaces. The Fischer handheld PHASCOPE® PMP10 instrument, used together with an ESD2.4 probe, is the ideal combination for this measurement task.

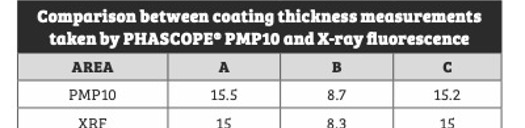

The following table compares the average values of the zinc thickness as measured with a PHASCOPE PMP10 to measurements taken with an XRF system:

Besides the coating thicknesses, the values also show the distribution of the zinc layer over the nails, indicating the quality of the plating. The results further illustrate how well the PHASCOPE PMP10 measurements correlate with those taken using X-ray fluorescence.

The handheld PHASCOPE PMP10 and the probe ESD2.4 together form an affordable measuring system that provides good precision and accuracy in a portable unit for quick and reliable testing of zinc-coated fasteners.

www.fischerinstrumentation.co.uk

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.