Here Cesare Certini, owner of S.M.T Srl – an independent Italian laboratory specialised in metallurgical testing, looks at the phenomenon of decarburisation during the heat treatment of fasteners and the steps that can be taken to control the undesired chemical reaction.

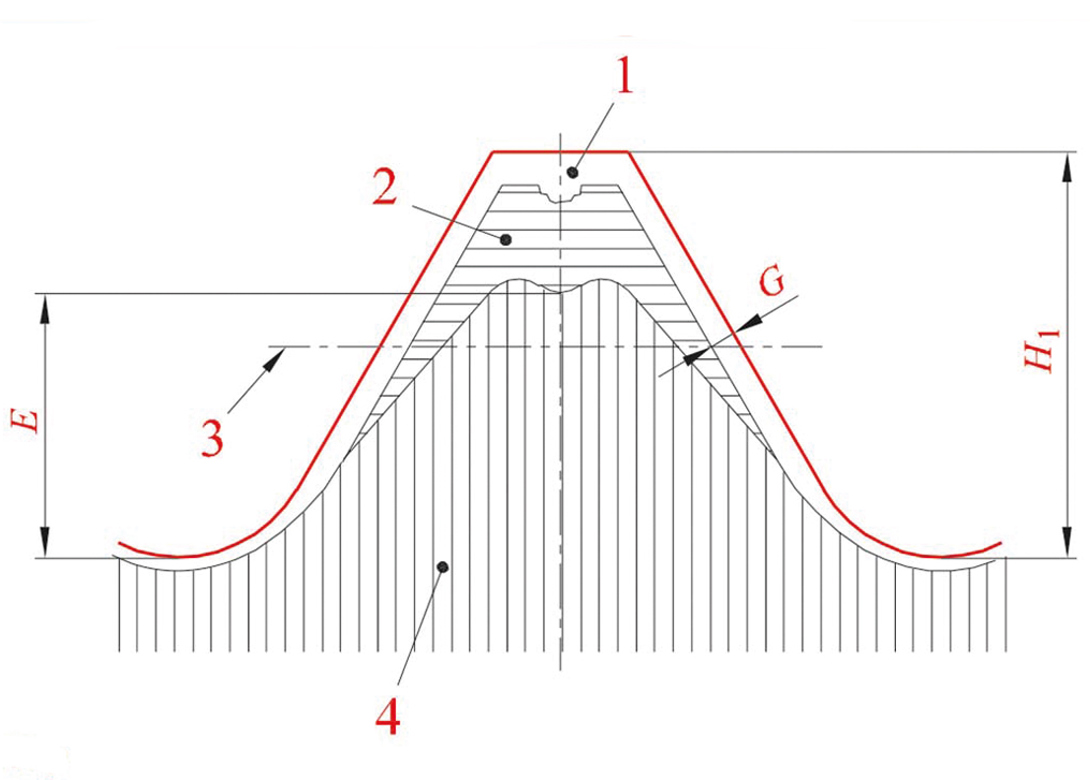

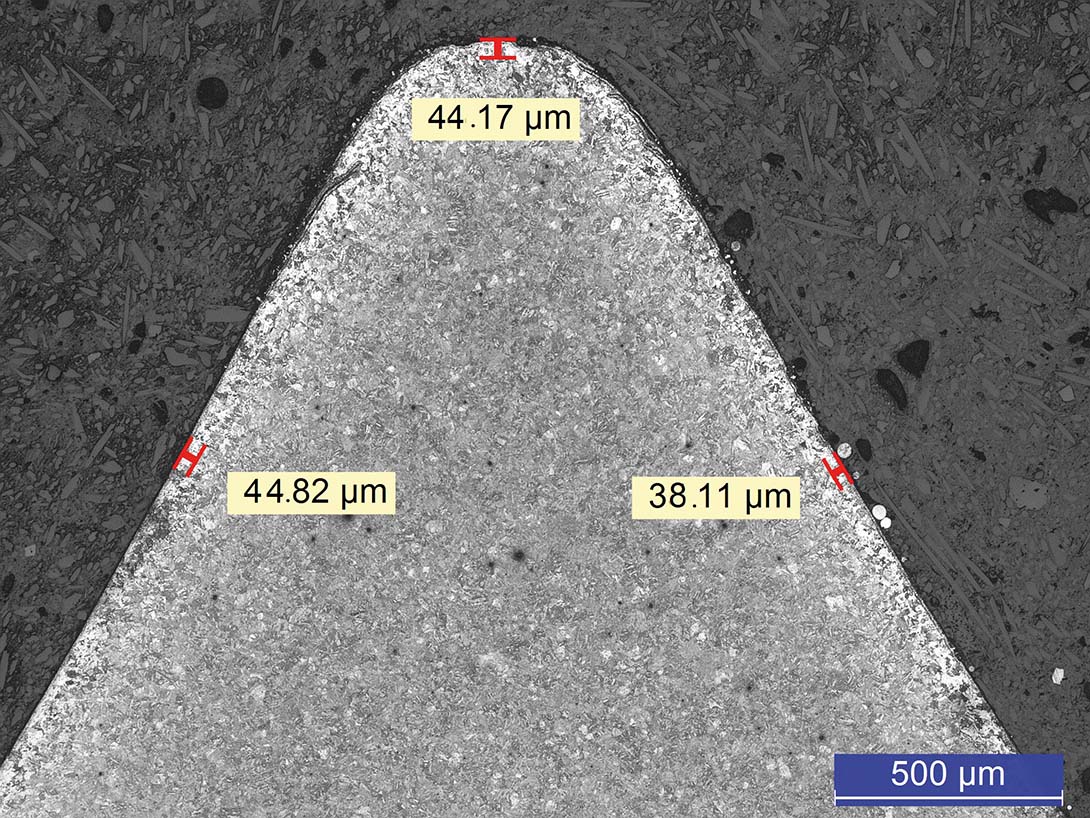

Some fasteners are subjected to quenching and tempering to increase the mechanical properties and to have structures capable of ensuring good toughness. In the case of the EN ISO 898-1 standard, it is mandatory to carry out this heat treatment for classes 8.8, 10.9 and 12.9.  (Figure 1)

(Figure 1)

This heat treatment can be performed on the raw material (wire rod or bar) or on the threaded part and can cause decarburisation, a detrimental chemical reaction that involves a loss of carbon on the surface of the steel.

At high temperatures, more precisely above the Ac1 transformation point, the carbon present on the superficial parts of the steel reacts with oxygen present in the atmosphere of the furnace to generate carbon monoxide (CO), which being a gas disperses – reducing the carbon present in steel.

This is a phenomenon that mainly affects steels treated in non-controlled atmosphere furnaces but also in the case of furnaces protected with inert gases it is possible to have decarburisation due to incorrect settings, not perfect sealing of the furnace, etc. The surface loss of carbon has a negative effect because it reduces surface hardness, resistance to fatigue and wear.

For this reason, the EN ISO 898-1 standard provides a control of the decarburisation of the thread with the aim of determining the depth of the area with complete decarburisation.

This standard allows two different types of decarburisation control – the microscopic method and the hardness method.

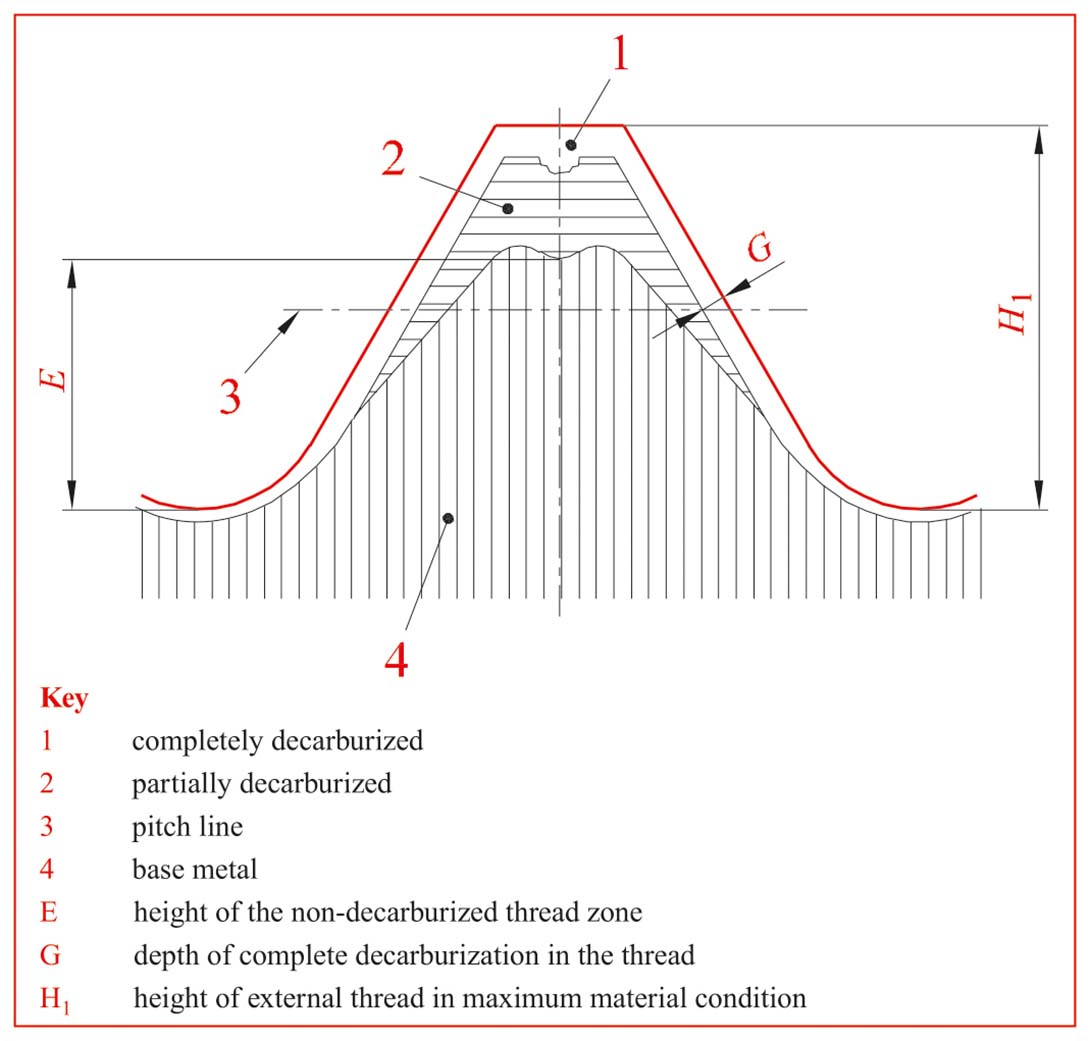

(Figure 2)Microscopic method

For the microscopic method the sample must be taken in the longitudinal direction, polished and then pickled with 3% nital (solution consisting of alcohol and 3% nitric acid).

After this, the sample should be observed under the microscope at 100X and the depth (G) of complete decarburisation measured (Figure 1), made evident by the presence of a completely ferritic structure (Figure 2).

Another parameter that must be measured is the height (E) of the base metal, which must have a minimum value depending on the pitch thread (P). In the case of P ≤ 1.25mm, the microscopic method is the only one that can be used.

Hardness method

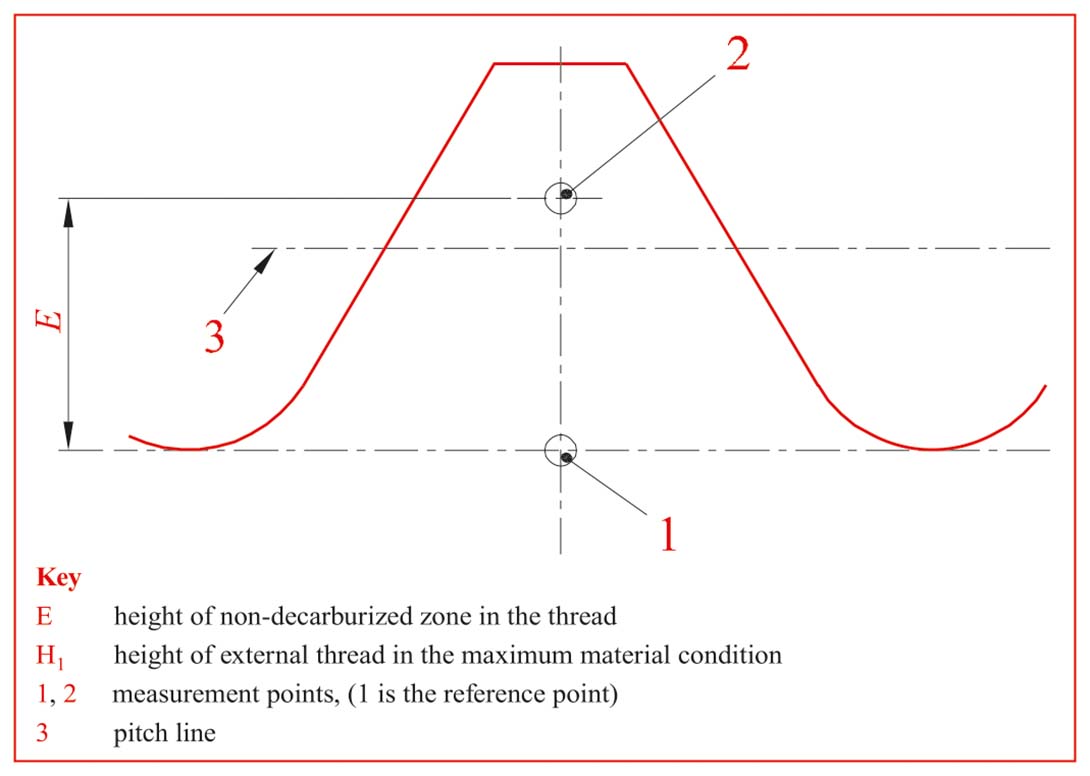

For the hardness method the sample must be prepared as shown in the previous case and then two Vickers HV0.3 hardness tests must be performed in points 1 and 2 (Figure 3).

(Figure 3)

The sample can be considered free from decarburisation if the hardness value HV0.3 in point 2 is equal to or greater than the hardness measured in point 1 minus 30 Vickers points. The height of the non-decarburised area is a function of the pitch thread.

Differences between the two methods

The hardness method has the advantage of being an objective and not subjective method like the microscopic method, which is subject to the interpretation of the metallograph. However, the hardness method has the limit of being usable only with a pitch thread greater than or equal to 1.25mm and does not allow for the measurement of complete decarburisation.

At S.M.T we have a laboratory that can perform both methods perfectly, in full compliance with current regulations. In the case of the microscopic method, the measurements are performed automatically using an image analyser, as well as in the case of the hardness method, where a dedicated software of the Vickers hardness tester is able to detect the hardness values in a precise and automatic way.

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.