Transvalor S.A is a company that provides best-in-class, affordable and flexible solutions to simulate fastener manufacturing. Thanks to its FORGE® and COLDFORM® software, users get strong performing solutions together with the support of a team of experts for consulting services.

At every step of the manufacturing process, engineers can take advantage of virtual manufacturing. Transvalor states that simulation is a crucial strategic mean for the development of high performance fasteners.

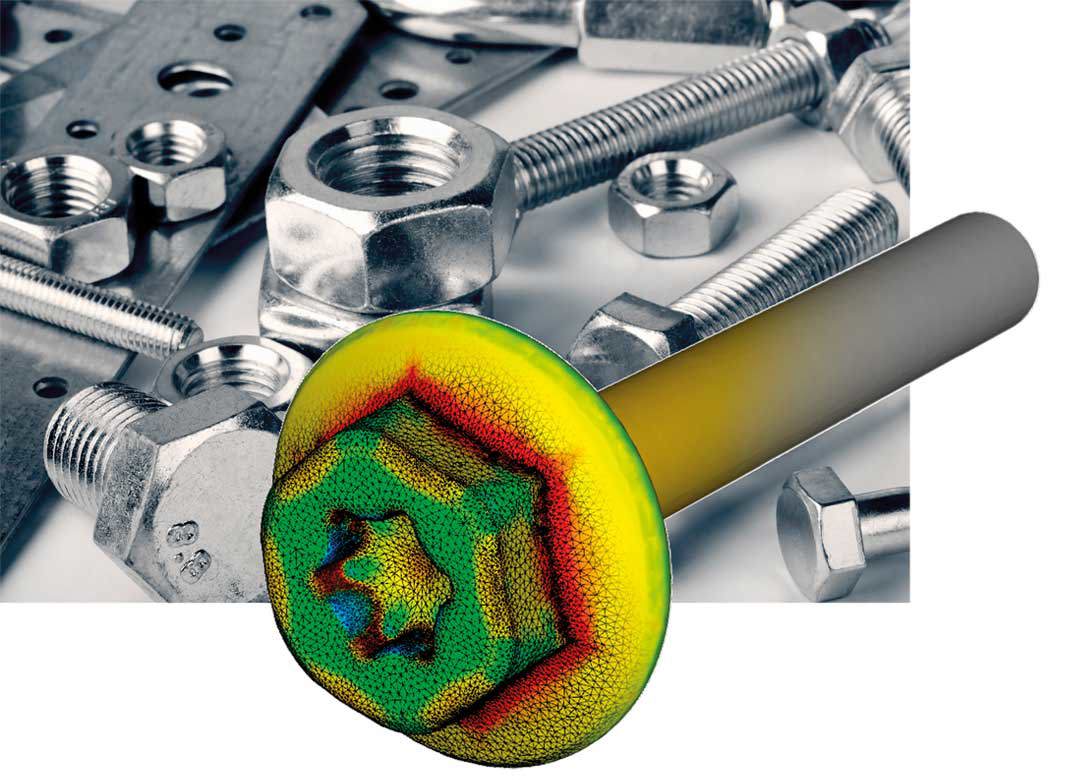

The software is relevant to simulate the entire manufacturing process from wire blank cut-off through to the cold heading sequence, thread rolling and final heat treatments. Moreover, by bridging process simulation and product analysis, one can simulate the response of fasteners under stress loading and consider the impact of residual stresses due to prior forming sequences.

Simulation contributes to mastering the process and improving the quality of products. It also:

Transvalor points out that virtual manufacturing is a unique opportunity to drive costs down and differentiate from the competition. One can eliminate the cost of trials and errors, select the right forming equipment and avoid premature die failure. Consequently, the engineering team can demonstrate that high-quality forgings will be delivered in a timely manner.

“For our customers, Transvalor’s simulation-based approach enhances the knowledge of manufacturing techniques and effectively accelerates time to market for new products,” says Stéphane Andrietti, marketing director at Transvalor.

Competitive advantages also include optimising existing processes and increasing productivity, daring new designs for innovative projects, and an easy decision when replying to requests for quotations.

“With Transvalor software there is no trade off on quality. All features are available without extra or hidden options. Customers can lease or purchase a licence or enquire about engineering consulting. Our experts in simulation will provide the most appropriate services to match expectations,” comments Stéphane.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.