Lightweight anchoring

08 December 2016

In 48 years Mungo Befestigungstechnik AG has gained the experience and technical know-how to develop innovative and technical solutions – whilst guaranteeing Swiss quality. Here the company focuses on the different types of lightweight anchoring and the benefits.

The guideline ETAG 001 Part 6 (used as a European Assessment Document – EAD) represents the base for issuing a European Technical Assessment (ETA) for metal anchors for multiple use in non-structural applications in concrete. In this case, non-structural (in the ETAG 001 Part 1 [2], also called light systems) stands for building elements, which do not contribute to the stability against the collapsing of the building. Examples for such constructions are light suspended ceilings, ductwork as well as façade coverings, and are therefore mostly called lightweight fixings or anchors.

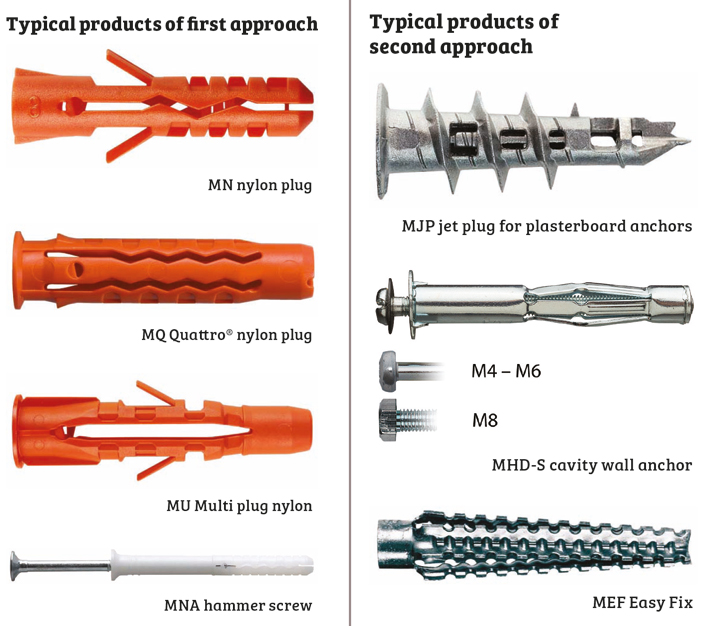

If a customer enquiries for technical literature or looks at the homepages of diverse producers of fastening technology, this definition gets extended by many more products and the boundaries to middle or heavy-duty fixings/anchors blurr quickly. In general, you can find two definitions determined by two different approaches:

First approach

Anchors of lightweight add-on parts such as pictures, lamps, rails, light switches, etc, are called lightweight fixings/anchors.

In this case, the installer can forgo an overdesigned and expensive anchor, because the attached part is rather light and the requirement to the load values are rather low. The installer mostly uses a multifunctional product, which can be applied by means of different connection types. Dependent of the given ground material, they mostly create a friction or a mechanical interlock. The most common product is the conventional nylon plug such as MN, MQ, MU or MNA hammer screws.

Second approach

Anchors in building materials such as masonry, gypsum plaster boards, aerated concrete, etc.

More problems arise, when it comes to fixing/anchoring in an unstable underground material. In this case, the use of mid weight or heavy-duty anchors is not possible because of the weakness of the base material. For this application, lightweight anchors with very specific properties have to be applied. Normally, the used anchors work with the mechanical interlock connection type to distribute the loads on as much ground material as possible – to reach the highest possible load. Usually, they are limited by the weakness of the ground material.