By Ian Parker, freelancer, ianfliesrussian@aol.com

Airlines have had a double-whammy from the Covid-19 pandemic and environmental concerns, so they will be looking for very different planes in the future – possibly even electric planes.

Keeping many passengers close together in the airport and on the plane, breathing the same air, and then burning kerosene to the destination will both have to go. Aircraft layouts and propulsion will have to change quickly if the travel levels of recent years are to be maintained or exceeded.

Providing passengers with clean, uncontaminated air will be as important as providing the powerplants with non-polluting energy. The latter will probably come from the use of hydrogen, either directly as a fuel, or in the production of electricity in hydrogen fuel cells for powerful motors. However, hydrogen has to be kept very cold to maintain it in a liquid state and those low temperatures offer a major advantage to systems that use a large amount of electrical power – superconductivity can be employed.

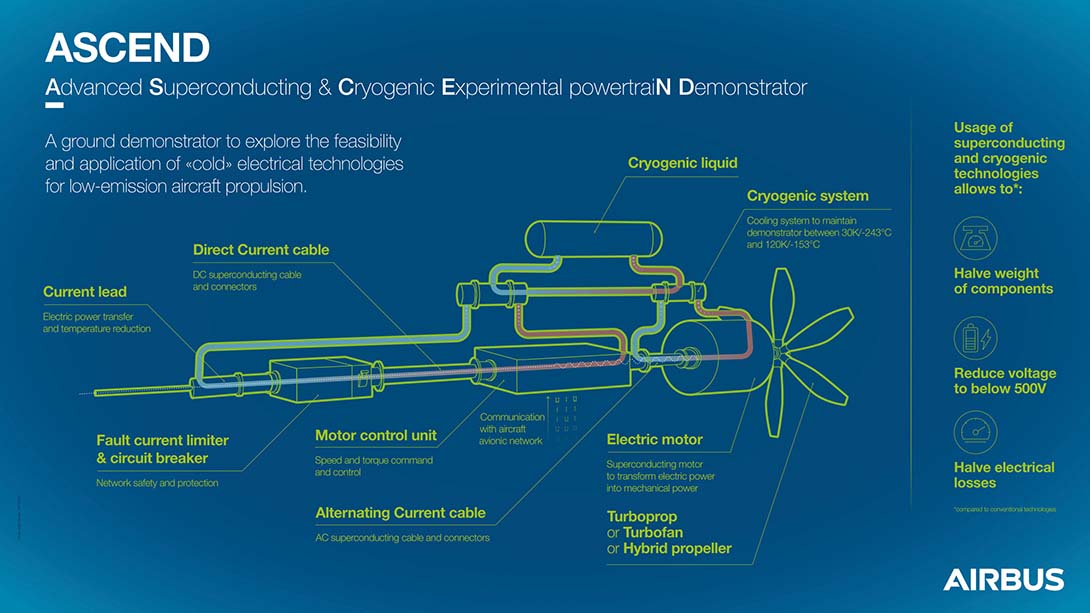

To exploit such principles, Airbus has launched its ASCEND project – a major breakthrough in electric propulsion for long-range aircraft could soon be on the horizon. The presence of a cold source, in the form of liquid hydrogen, alongside superconducting technologies promises to unlock new possibilities. Today, the ASCEND demonstrator project by Airbus UpNext aims to mature these technologies to significantly boost the performance of electric and hybrid-electric propulsion systems in future low emission aircraft.

What is superconductivity?

In 1911 Dutch physicist Heike Kamerlingh Onnes found himself preoccupied with one question: ‘What happens to the electrical conductivity of pure metals at very low temperatures?’ During an experiment, he immersed a wire made of solid mercury into liquid helium and, to his astonishment, found the wire’s electrical resistivity completely vanished at 4.2°Kelvin (-268.95°C).

He called the phenomenon ‘superconductivity’ or the ability of certain materials to generate strong magnetic fields and conduct very high electric currents with practically zero resistance when exposed to very low temperatures. The discovery was so groundbreaking, it earned Kamerlingh Onnes the 1913 Nobel Prize in physics.

Today, superconductivity has a variety of practical applications, including:

However, superconductivity’s applications in the aerospace industry have yet to be fully explored. Airbus UpNext is looking to change that with its latest ground-based demonstrator project called ASCEND (Advanced Superconducting & Cryogenic Experimental Powertrain Demonstrator). Sandra Bour Schaeffer, CEO at Airbus UpNext, comments: “With the ASCEND demonstrator, we’ll pave the way for a real breakthrough in electric propulsion for future aircraft.”

The twin power of cryogenics and superconductivity

One of the major challenges of scaling up electric propulsion to larger aircrafts is the power-to-weight ratio. In other words, today’s electrical systems simply do not meet the necessary power requirements without adding excess weight to the aircraft. However, high-temperature superconducting technologies are emerging as a promising solution to this technical conundrum, notably by increasing power density in the propulsion chain – while significantly lowering the mass of the distribution system.

This is where ASCEND comes in. The three year demonstrator project aims to show that an electric or hybrid-electric propulsion system, complemented by cryogenic and superconducting technologies, can be more than 2 to 3 times lighter than a conventional system – through a reduction in cable weight and a limit of 30kW/kg in power electronics – without compromising a 97% powertrain efficiency.

To achieve this objective, ASCEND features a 500kW powertrain consisting of the following components:

“With the ASCEND demonstrator, we’ll adapt ground-based cryogenic and superconducting technologies to a fully electric powertrain to confirm their potential at aircraft level,” explains Ludovic Ybanez, head of the ASCEND demonstrator. “Integrating these components will not only be a world first, but also an essential step towards future full-scale tests and flying demonstrators.”

Cool hydrogen

Cool hydrogen

In addition to optimising the weight of the distribution system, another objective of ASCEND is to significantly increase the power density of the propulsion chain. This is a key consideration, as increasing the power of current electrical aircraft systems from a few hundred kW to the MW required for a fully electric aircraft is no easy feat. Simply put, more power increases weight and installation complexity, and generates more heat.

However, if a cold source at 20°K (-253.15°C), such as liquid hydrogen, is available on board, it can be used to cool the electrical systems. The superconducting components can then work to significantly improve the power density of the electric-propulsion systems.

Airbus is already looking into how liquid hydrogen could be used as fuel for an internal combustion engine or fuel cell as part of its ZEROe pre-programme. The ASCEND demonstrator will thus complement this research by providing additional insight into how cryogenic and superconducting technologies can support an ultra-efficient electric and/or hybrid-electric propulsion system for future aircraft.

“With the ASCEND demonstrator, we’ll pave the way for a real breakthrough in electric propulsion for future aircraft,” says Sandra Bour Schaeffer. “The importance of this work can’t be overstated. Cryogenic and superconducting technologies could be key enablers to enhancing the performance of low emission technologies, which will be essential to achieving our ambitious decarbonisation targets.”

The fastener issues

Aerospace fasteners are already in a high spec category. How will they have to be developed to take on these new high voltage/low temperature environments?

There are tens of thousands in the average passenger jet. Aircraft fasteners are very different from commercial grade fasteners and the two should never be confused. Although the average commercial grade fasteners are high performance items in themselves, the two can’t be compared.

Aerospace bolts are made from corrosion resistant steel and are heat treated to exceed a tensile strength of 125,000 psi. Commercial grade fasteners, by contrast, are made using low carbon steel. They bend easily and have very little corrosion protection. Their tensile strength is measured somewhere between 50,000 psi – 60,000 psi.

Many aerospace standards are common with those in the military because that’s their origin. The commercial aviation industry has its roots in the technology developed during World War II, so much of the safety measurements and terminology used was first defined by the US and British military.

Bolts

The difference between an aerospace quality bolt and a commercial one is in the quality and cost of the materials. Aircraft standard bolts are made with alloy steel, stainless or corrosion resistant steel, aluminium alloys and titanium. These allow the bolts to be both lighter and stronger than their commercial counterparts. They typically have a tensile strength of around 160,000 psi.

Nuts

The nuts found on aircraft are distinctive in two major ways. Firstl they are all constructed from the same materials listed above. Secondly, because of the vibration caused by flying, and the extreme pressures they can be placed under, all aerospace quality nuts have some form of locking device to keep them in place. These are commonly known as castle nuts, lock-washers, safety wire and fibre inserts.

Washers

Simply put, washers are used normally as you would expect, however like the nuts and bolts listed above they are constructed from stronger more lightweight materials.

Fastener covers

These are widely used in the industry to cover the nuts, bolts and washers already listed. Manufacturers employ a wide range of specialist materials as they need to be resistant to the many environmental factors within our atmosphere. Such materials include cadmium, zinc, nickel, silver, phosphate and black oxide.

Even the tiniest amount of extra weight will have a huge impact on aircraft performance, so aerospace fastener design becomes a combination of engineering and physics with a strict adherence to the highest quality materials, design and manufacturing standards.

The most commonly used materials are:

The most commonly used materials are:

So aerospace fasteners are often exposed to low temperatures, but rarely are they exposed to high voltages. In the automotive sector, new energy vehicles (NEVs) need safe energy storage and delivery to the propulsion on demand. This requires electronic control mechanisms, which cannot be disrupted by electro-magnetic waves or affected by corrosion, contamination or moisture. This is where there will be a growth in uptake of isolating coatings and non-magnetic fasteners. Initial NEV designs used bolted-on batteries, whereas new designs are looking to integrate the battery assembly as part of the structural design of the vehicle.

Battery retention bolts and compression limiters are playing a large role in the materialisation of these designs to allow transfer of forces through the structure, whilst allowing access for repair and maintenance. Well designed cable management will secure the ever growing wiring looms for delivery of energy to all parts of the vehicle and report back any key information picked up by the multiple sensors.

Another factor of very low temperatures is embrittlement. A substance that is extremely strong at normal temperatures can be very brittle when near absolute zero. Austenitic stainless steels such as 304 (1.4301) and 316 (1.4401) are however ‘tough’ at cryogenic temperatures and can be classed as ‘cryogenic steels’. They can be considered suitable for sub-zero ambient temperatures sometimes mentioned in service specifications for sub-arctic and arctic applications and locations, typically down to -40°C.

The vast majority of fasteners in airliners will remain unchanged, but those used in superconducting cryogenic power systems will face a range of stresses connected with very low temperatures and high voltages. Just what those stresses are will be part of what comes of Airbus’s development of ASCEND… and the fastener industry will be expected to respond accordingly.

Acknowledgment: The author thanks JP Aero for input to this article

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.