One of the biggest frustrations nail producers face is downtime, from box changes to locating and fixing issues. That is why the latest version of the ENKOline, from ENKOTEC, is designed to minimise downtime and reduce labour intensity.

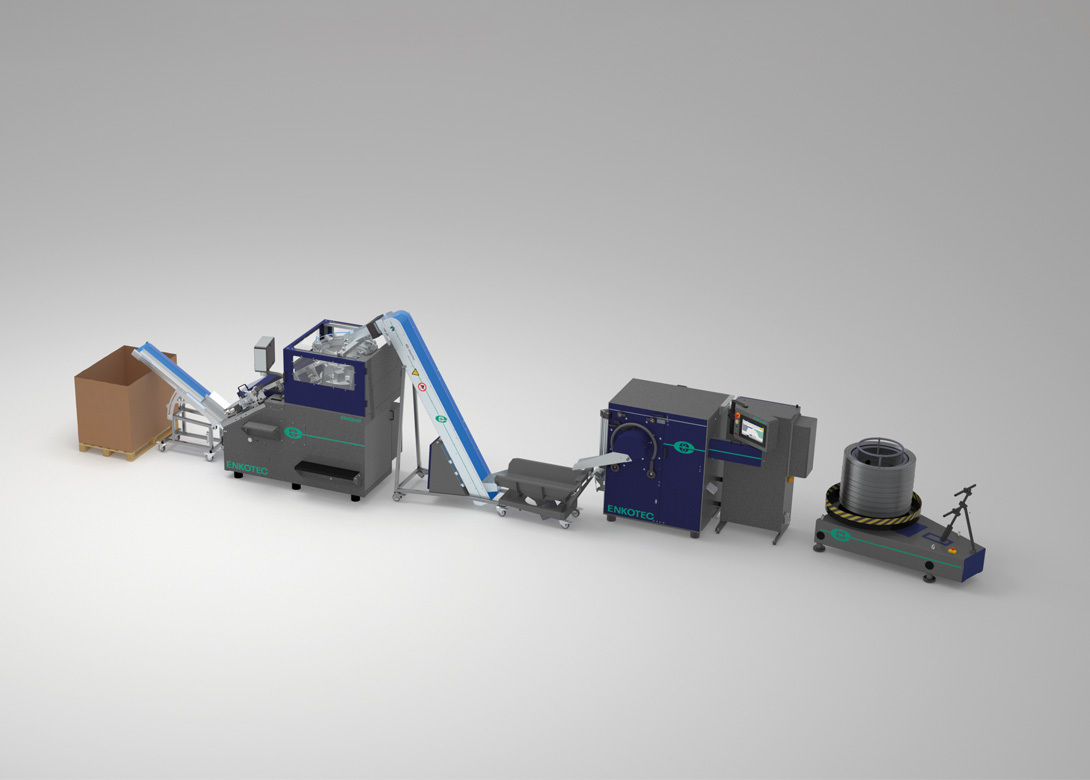

When placed in an in-line configuration with the ENKOveyor magnetic conveyor, ENKOroll thread rolling machine, as well as the ENKOveyor Smart Belt conveyor, the ENKOline functions as a complete end-to-end nail production solution. Equipped with the ENKOsmart software platform – an advanced system of interconnected applied sensor technology that allows the individual machines in the line to communicate with each other – the new ENKOline offers a range of advantages such as automatic nail transportation, a reduced footprint and auto-stop/start capabilities.

For example, when the ENKOveyor Smart Belt conveyor senses the nail box at the end of the line is almost full, it will send a signal to put the thread roller into idle mode, which will in turn send a signal to the magnetic conveyor in front of the thread roller and the nail machine, causing them to stop. This allows the operator to change the box without having to shut down the whole line. As soon as the ENKOveyor senses that the box has been changed, it will send a signal to the other machines to resume their normal production, automatically starting up the line again.

This saves valuable time and makes it possible for one operator to manage multiple ENKOlines at the same time – significantly increasing production efficiency in comparison to other in-line or batch production set-ups. The ENKOline can also be arranged in a number of configurations to suit floorspace and needs – including a range of collating solutions, which will be demonstrated by ENKOTEC at the upcoming wire® Düsseldorf show.

The advanced sensors, and ENKOsmart software platform, also enables users to monitor nail production and collect data about the machine’s performance, such as precision quality control and intelligent error tracking, which can be viewed on an interactive touchscreen – making it easy to spot opportunities for improvement.

If an error should occur, the sensors can accurately identify it and report it on the touchscreen interface. This means repairs can begin straight away, eliminating the downtime usually needed to discover the cause of the problem. The screen also features a digital manual and intuitive video guides to make maintenance and repairs as quick and easy as possible.

The ENKOsmart system also delivers a solution to one of the most frustrating issues in any production industry – waiting for support. It provides a unique opportunity for remote connectivity, which facilitates ‘real time’ troubleshooting and support from a team of expert service engineers at ENKOTEC HQ. This significantly reduces downtime as many issues can be resolved remotely with specialist guidance – getting the machines up and running again as quickly as possible.

www.enkotec.com

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.